25

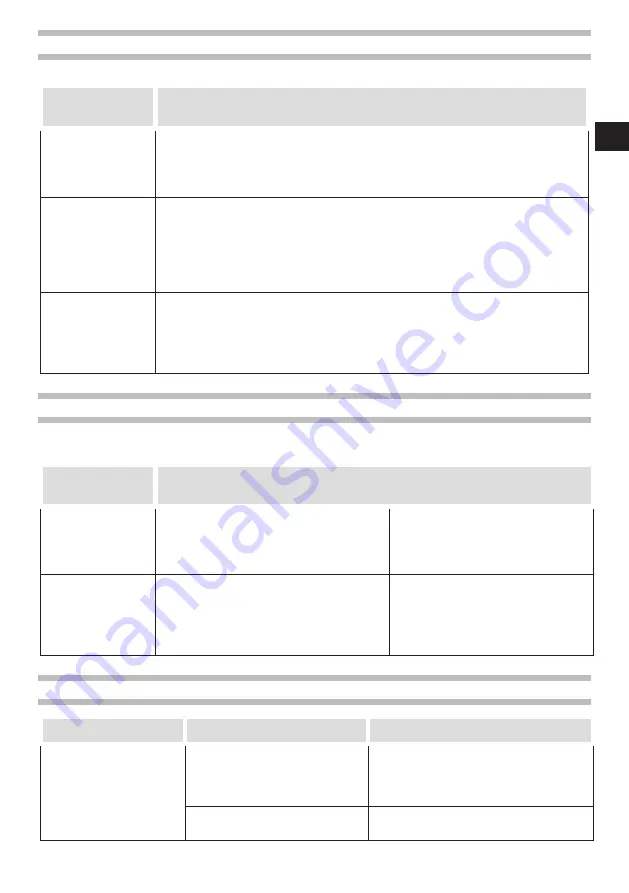

ROUTINE MAINTENANCE

Follow the instructions for

“STOPPING WORK”

and those provided in the table below.

MAINTENANCE

SCHEDULE

ACTION

Ever y time the

cleaner is used

• Check the power cord, the high pressure hose, the connectors, the cleaner

gun and the lance pipe.

Should any of these look damaged, do not use the cleaner for any reason and

contact a

Qualified Technician.

Once a Week

• Check the water inlet filter (29) and clean it if necessary.

Unscrew the cup (28) and remove the filter (29).

Running water or compressed air is generally all that is needed to clean the filter.

In the most difficult cases, use a limescale remover or replace it, contacting a

Specialized Technician

to buy the spare part.

Mount the filter again, following the above steps in reverse order.

Once a Month

• Clean the nozzle.

To clean the nozzle, it is generally sufficient to insert the pin (22) supplied into the

nozzle’s hole. If no appreciable results are obtained, contact a

Qualified Technician

to buy the spare part. The nozzle can be replaced using a 14 mm/0.55” spanner

(not supplied).

SUPPLEMENTARY MAINTENANCE

Supplementary maintenance should only be carried out by a

Qualified Technician

, following the table

below (guideline only):

MAINTENANCE

SCHEDULE

ACTION

Every 100 hours

• Check the pump’s hydraulic circuit (water).

• Check the pump is firmly secured.

• Adjust the electrodes.

• Check/top up the pump’s oil level.

• Clean the fuel nozzle.

• Check/replace the fuel filter.

• Check/replace the water filter.

Every 300 hours

• Change the pump oil.

• Replace the electrodes.

• Replace the fuel nozzle.

• Check the pump delivery/suction valves.

• Check the tightness of pump screws.

• Check the pump’s adjustment valve.

• Clean the boiler.

• Remove any lime scale on the

heating element.

• Check the safety devices.

TROUBLESHOOTING

PROBLEM

CAUSE

SOLUTION

The cleaner does not

start when the master

switch (1) is turned to

“I”

.

A safety device has been tripped

on the system where the cleaner is

connected (a fuse, circuit breaker,

etc.).

Reset the safety device.

SHOULD IT TRIP AGAIN, DO NOT USE THE

CLEANER AND CONTACT A QUALIFIED

TECHNICIAN.

The plug has not been inserted

properly in the power outlet.

Disconnect the plug and reconnect it

correctly.

(continued on next page)

GB

Summary of Contents for IP 2500 HS

Page 2: ......

Page 4: ...1 9 10 7 3 3 11 11 B A...

Page 5: ...2 2 1 4 3 7 6 5 8...

Page 6: ...3 C T max kW 12 13 14 15 16...

Page 7: ...4 1 31 6 2 D 37...

Page 8: ...5 18 19 20 20 21 22 19 23 24 17 25 27 26 29 28 30 C...

Page 9: ...6 32 33 34 E...

Page 10: ...7 26 18 19 22 17 5 F G H 27 25...

Page 11: ...8 4 29 28 35 I 36...

Page 70: ...70 1 0 23 10 15 24 23 18 5 C a...

Page 73: ...73 23 26 6 7 29 28 29 4 22 14 mm 0 55 in 100 GR...

Page 74: ...74 300 1 I 29 33...

Page 75: ...75 Total Stop 1 38 GR...

Page 86: ...86 1 0 23 10 15 24 23 18 5 C...

Page 89: ...89 29 28 29 4 22 14 0 55 100 300 RUS UA...

Page 90: ...90 1 I 29 33...

Page 91: ...91 Total Stop 1 RUS UA...

Page 131: ......