Construction Manual

www.oldschoolmodels.com

Page 17

Optional canopy

Included is a canopy and

though it's certainly up to you

if you choose to use it, the

canopy is just a defining part

of the Lark's' outline, so why

not use it?

The following steps will

describe how to properly prepare and attach it.

• Trim along it’s flat edge. You’ll want to trim away the excess

plastic and leave a smooth lip, roughly 3/16” wide around the

it’s perimeter.

• Place it on the fuselage and make sure it's lays flat on the top of

the sheeting. Not all canopies are exactly identical, so a bit of

trial and error is needed to get a good fit.

• If you’re going to add a pilot figure (not included), now is the

time to test-fit, then glue it in place.

• Give the canopy a quick wash in warm, soapy water.

• If you're going to tint or paint the canopy, do this on the inside

now and allow it to try.

• Use a bit of canopy glue to attach the canopy. So it doesn't

move while the glue cures, hold it in place with a bit of low-tack

masking tape.

This completes the assembly of the Lark. Now you’ll need to

adjust the control throws and check for balance.

Recommended C.G. setting:

An important part of preparing the aircraft for flight is properly

balancing the model. This is especially important because of the

various motor/battery combinations that can be used.

CAUTION! DO NOT SKIP THIS STEP!

The recommended Center of Gravity (CG) range for the Lark is 3.1"

from the leading edge of the wing, and you’ll see this marked on

the fuselage plan with this symbol.

If necessary, move the battery, receiver,

and/or add weight to either the nose

or the tail until the correct balance is

achieved. Stick-on weights are available

at your local hobby store and work well

for this purpose.

We recommend balancing it at the

forward point for the first flights, then moving it backward if you'd

like it to be a little more maneuverable.

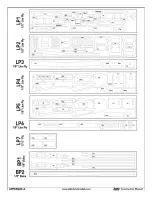

Recommended Control Throws:

The amount of control throw should be adjusted as closely as

possible using mechanical means, rather than making large

changes electronically at the radio.

By moving the position of the clevis at the control horn toward

the outermost hole, you will decrease the amount of control throw

of the control surface. Moving it toward the control surface will

increase the amount of throw. Moving the pushrod wire at the

servo arm will have the opposite effect: Moving it closer to center

will decrease throw, and away from center will increase throw. Work

with a combination of the two to achieve something relatively

close to these throws that are good for everyday sport flying. If

competing in pattern, you'll probably want to dial these down a bit

to give a smoother appearance to your maneuvers.

Aileron 3/8” up/down (25% expo)

Elevator 1/4” up/down (20% expo)

Rudder .75” left/right (15% expo)

(Expert tip: Once the control throws have been set, cut a few

pieces of medium silicone fuel tubing (or heat shrink tubing) to

go around each of the clevises. This will keep them from opening

during flight.)

Preflight:

Charge both the transmitter and receiver pack for your airplane.

Use the recommended charger supplied with your particular radio

system, following the instructions provided with the radio. In most

cases, the radio should be charged the night before going out

flying.

Check the radio installation and make sure all the control

surfaces are moving correctly (i.e. the correct direction and with

the recommended throws). Test run the engine and make sure it

transitions smoothly from idle to full throttle and back. Also ensure

the engine is tuned according to the manufacturer’s instructions,

and it will run consistently and constantly at full throttle when

adjusted.

Check all the control horns, servo horns and clevises to make

sure they are secure and in good condition. Replace any items

that would be considered questionable. Failure of any of these

components in flight would mean the loss of your aircraft.

Range check your radio before flying

Before each flying session, range check your radio. This is

accomplished by turning on your transmitter with the antenna

collapsed. Turn on the radio in your airplane, but do not attach the

arming switch.

With your airplane on the ground, you should be able to walk 30

paces away from your airplane and still have complete control of

all functions.

If not, don’t attempt to fly! Have your radio equipment checked

out by the manufacturer.

Warranty Information

Old School Model Works

guarantees this kit to be free from defects in both

material and workmanship at the date of purchase. This warranty does not cover

any parts damage by use or modification. In no case shall

Old School Model

Works’

liability exceed the original cost of the purchased kit. Further,

Old School

Model Works

reserves the right to change or modify this warranty without notice.

In that

Old School Model Works

has no control over the final assembly or

material used for the final assembly, no liability shall be assumed nor accepted for

any damage of the final user-assembled product. By the act of using the product,

the user accepts all resulting liability.

Limit of Liability

In the use of this product, our only obligation shall be to replace such quantity

of the product proven to be defective. The user shall determine the suitability

of the product for his or her intended use and shall assume all risk and liability in

connection therewith.

If the buyer is not prepared to accept the liability associated with the use of this

product, the buyer is advised to return this kit immediately in new and un-opened

condition.

As of this printing, you are required to register with the FAA if you own this product.

For up-to-date information on how to register with the FAA, visit

https://registermyuas.faa.gov .

For additional assistance on regulations and guidance of UAS usage, visit

http://www.knowbeforeyoufly.org .