Page 16

www.oldschoolmodels.com

Construction Manual

servos are mounted to thicken the mounting surface for the servo's

screws. If using standard size servos for the elevator and rudder, you

may need to stack the TR3's two-high so the servos will clear things that

might interfere with the servo arms.

Take a bit of time to plan things out, including how you'll run the

throttle and nose gear steering pushrods.

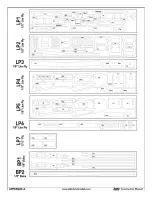

When mounting the servos to each of the SH's you'll need to cut

eight 3/4" lengths of the 1/4" square basswood scrap. Make four

thicker mounting posts by laminating two pieces together then

sand the ends flat.

Position your aileron

servo on the inside of

the aileron hatch so the

servo arm output shaft is

centered in the opening.

On the inside of each

aileron hatch, glue one

post on each side of the

servo as shown in the photo.

Note that the left hatch is a mirror

image of the right hatch.

Now fit the servo hatches into

position on the bottom of the wing.

Using the pre-cut holes as a guide,

drill four 1/16” mounting holes into

the basswood mounting posts you

just installed. Harden the wood with

a bit of thin CA and you can use the

supplied 2-56 x 3/4” self tapping screws to secure the hatches in

place.

Finish the layout of your radio gear by adding the receiver, flight

pack battery and the switch. We mounted the receiver to the

tray by using a bit of self-adhesive hook-and-loop (not included).

The radio's switch should be mounted to the opposite side

of the muffler (to help keep the goop out of it). Or, for an even

cleaner installation, it could be installed inside the tank/battery

compartment - hidden under the hatch - VERY NICE!

Covering

Now it is time to cover the Lark. Remove the powerplant, main

gear, nosewheel assembly, pushrods, and any other components

that would get in the way of applying the covering.

Double check that all surfaces are smooth and ready to cover. Sand

as necessary, then cover the entire airframe with the covering/finish

of your choice.

Note that if you’re powering with an electric motor, you’ll need

to make a hole for the cooling air to escape the bottom of the

fuselage, near the rear.

When the covering is complete, re-attach all the components you

removed earlier in this step.

Logos, numbers, etc.

If you want to use graphics similar to the

ones we used, Old School Model Works

has teamed up with Callie Graphics as a

supplier for pre-cut vinyl. They are a very

well known provider of custom graphics for

R/C models.

We have supplied them with the artwork

needed to cut the correct size logos. You can order straight from

them, choosing the colors that work for you.

Contact Callie Graphics at this link: https://callie-graphics.com or scan

the QR code.

Note that Callie Graphics is not affiliated with Old School Model

Works, nor does Old School Model Works generate any income

from this partnership.

Attach the Control Surfaces

Now is the time to attach all the control surfaces to the airframe, by

gluing the hinges in position with thin C/A. We've noted suggested

hinge locations for each of the control surfaces on the plans.

When using the CA hinges, first push a

pin through on side, at the center of the

hinge as shown here. This will keep the

hinge centered as it's pushed into the

surfaces. When you've got all the hinges

for a surface in place, then remove the

pins and glue the hinges.

Make sure that you attach the elevator

first, and make sure you cut away some

clearance to allow the elevator joiner to rotate freely and not

interfere with the fuselage.

When the elevator's in place, then attach the rudder.

And don't forget the ailerons.

Attach wheels

Use the included 5/32” i.d. wheel collars to hold each wheel (not

included) on the axles. For a maintenance free installation, file

a small flat on the axle where the set screw of the wheel collar

touches. Also use a touch of thread-locking compound to keep the

screw from loosening over time.