4

The scale behind the crank serves fro fine adjustment of the back gauge. The figures “0-9” show

in a enlarged from the mm of the side gauge scale. “0” means a whole cm, “1-9” the

corresponding mm.

The exact adjustment of the size is always don in a way that the back gauge pushes paper toward

the front.

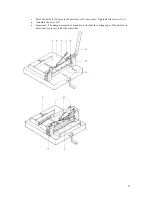

10. Back Gauge

Operation via the crank. For adjustment to the desired cutting size and for exact parallel placing

of the paper plies to be cut.

Do no use the back gauge for straightening the pile, as this will cause the gauge to move away

from the adjusted measurement and be inaccurate.

11. Side Gauge with Scale

In mm/cm and inch. For rectangular placing of the paper pile. The indicator on the back gauge

shows the measurement, which is adjusted on the scale of the side gauge. Fine adjustment is down

via the mm scale of the scale ring (#9).

12. Stand

Made of steel. Standard equipment of Model 3905 U.

Operation

•

The knife lever (#1) is locked in its top position.

•

Bring hand guard (#5) up. Push the paper pile into the machine from the front and place it against

the back gauge (#10) and along the side gauge (#11) on the left.

•

Push the back gauge crank (#9) toward the cutter to engage, and then turn the crank handle (#10)

clockwise to bring the back gauge toward the knife until the paper measurement is reached. With

the help of the fine adjustment ring, accurate measurement can easily be reached.

•

Release the back gauge crank (#9), so that the unintentional movement of the back gauge can be

prevented.

•

Throw the lever of the flick action clamping system (6) from the right to the left. When the flick

action clamping device touches the paper pile, apply quick pressure to the handle and then let go.

The paper pile is now secure.

•

Bring down the hand guard (#5).

•

Release the knife lock (#2) and bring down the knife lever (#1) using both hands. When the cut is

complete, move the knife lever to its top position until it locks.

•

Release the hand lever of the flick action clamp system (#6). Lift the hand guard (#5) upwards

and take the paper out of the cutter.

Regrinding

Please note – A dull knife does not cut accurately. The cutting of heavy paper or cardboard means

sharpening the blade more often keeping a spare knife on hand. Should you be unable to find a

local sharpening service, contact your dealer or distributor.

Cutting Stick