5

If the last sheet of paper pile does not cut through, even though the knife adjustment (#8) was

already adjusted to the left (+), the cutting stick (#4) should be changed, turned or rotated.

The cutting stick can be used two times on each side – which means 8 changes per stick.

The cutting stick (#4) fits into the machine table and can be lifted out with the help of screw

driver.

Please note – When the cutting stick is changed, the knife has to be readjusted. A knife which cuts

too deeply, not only damages the cutting stick, but the knife too.

Lubrication

From time to time all moving parts have to be lubricated and oiled.

Before lubricating, these parts should be cleaned from paper dust and old deposits of oil and

grease.

Knife Change

Precise cuts are only possible with a sharp knife. The knife should be changed as soon as the

quality and the accuracy of a cut are not in accordance with the standards expected from this

cutting machine. If the knife should jam in the paper pile or leave grooves in the paper, the knife

must be changed immediately. Knife life with normal paper is approximately 20 working hours;

of course, this will vary with different types of paper. The knife change must be executed by one

person only. The cutting edge of the knife is extremely sharp. In order to avoid injuries, the knife

has to be h andled with the utmost care.

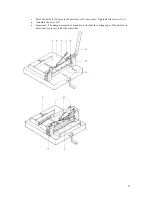

A knife change has to be down from the front of the machine as follows:

a.

The knife lever (#1) is locked in the top position.

b. Remove the 2 screws in the cover (#7). Unlock knife level (#1) and turn it slightly to the left.

Then take off the cover (#7).

c.

Return the knife lever (#1) to its starting position and lock it.

d. Open the hand guard (#5) to the top.

e.

Remove knife screws (B and D) and replace them with the two knife holders from the tool

box. Tighten securely. Take out knife screws (A, C and E).

f.

Loosen knife holders and lower the knife downwards from the knife carrier. Then, due to the

length of the knife, a sideways movement between the knife guide plates is required for

removal.

g. Turn or rotate the cutting stick (#4).

h. Turn back adjusting screws (F) until they reach the top edge of the knife carrier.

i.

Insert knife holders into second and fourth threaded hole (B and D) of the sharp knife. Place

knife (#3) into knife carrier and secure with knife holders.

j.

Screw in knife screws (A, C and E) – snuggly, don’t tighten. Remove knife holders. Screw

in knife screws (B and D) – snuggly, don’t tighten.

Caution: Do not leave the allen wrench in the knife screws.

k. Move the knife (#3) carefully down to the cutting stick (#4) via the knife lever (#1).

l.

Turn the knife adjustment (#8) to the right (-) until you have a visible ray of light between

knife edge and cutting stick (#4).

m. Adjust knife (#3) to the height of the cutting stick by means of the adjusting screws (F).

Screw in the middle first.

n. Move knife lever (#1) upwards and lock it. Make a trial cut with one sheet of paper. If the

paper is not cut through totally, the knife has to be adjusted via the adjusting screws (F).