MAINTENANCE AND CARE

Visual Inspection

a) Smooth safety and trigger movement.

b) All screws are tightened.

c) Never use damaged or incomplete tool.

Cleaning

The periodical cleaning of the tool is recommended to ensure proper functioning.

a) Disconnect the tool from the air supply.

b) Remove all fasteners

c) Clear the magazine and nose sections with a blowgun to remove any accumulated debris.

d) Check for free movement of the trigger, follower and work contact element. Remove any

obstructions carefully.

e) Oil tool daily with proper air tool oil.

f) Empty the air tanks on your compressor daily to prevent moisture buildup in the air lines.

Lubrication

The tool should be lubricated daily.

a) Add a few drops of non-detergent oil in the tool air inlet before each use.

b) Never use detergent oils, which can damage o-rings causing the tool to malfunction.

c) Wipe off excessive oil from the exhaust.

d) Hammer cage set should be periodically lubricated

– at least one time per month

Excessive oil will damage o-rings of tool.

WARNING:

Stop using the tool immediately if any of the following problems occurs. Serious personal injury could

occur. Necessary repair of replacement must be carried out by qualified and trained technician of an

authorized service location.

OEM Limited One Year Warranty

For one (1) year from the date of purchase OEM tools will warranty this tool against defects in materials

and workmanship. Defective OEM brand hand tools purchased from an authorized OEM distributor will be

repaired or replaced when returned freight prepaid to the OEM Warranty Dept., 3580 E. Raines Rd. #3,

Memphis, TN 38118. Proof of purchase with date of purchase will be required with all returns. OEM will

not be responsible for any consequential or incidental damages arising from the breach of this or any

other warranty, whether expressed, implied or statutory. Some states do not allow the exclusion or

limitation of consequential or incidental damages, so the above exclusion may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

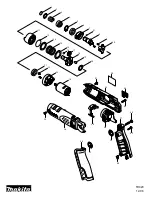

Summary of Contents for 24402

Page 7: ......