5

Operating Instructions and Parts Manual

24820 / 24821

BODY REPAIR KIT

8/17

2017 OEMTOOLS

™

5. Aim the pushing end towards the damaged area and

slowly apply pressure with the pump.

6. Once contact is established at each end, keep

clear as well as practical and slowly apply

pressure to the damaged area until the desired

correction has been made.

CAUTION

:

KEEP HANDS AWAY FROM CONTACT

AREAS AND TIGHT SPACES IN CASE THE

COMPONENTS SHOULD SLIP AND CAUSE INJURY.

7. When the damaged area has been bent to the

desired position, slowly turn the release valve on the

pump unit in a counterclockwise direction to release

hydraulic pressure before removing the Ram.

USING THE SPREADER WEDGE

1. Determine the direction in which the metal needs

to be spread.

2. Remove any obstructions that are in the way and

could be damaged.

3. Place the Spreader Wedge so that the hinged arm

is resting against the part to be moved and the

stationary base is bearing against a rigid support.

Hold the Spreader Ram in position and apply the

pump pressure.

4. Once contact is established at each end, keep

clear as well as practical and slowly apply

pressure to the damaged area until the desired

correction has been made.

CAUTION

:

KEEP HANDS AWAY FROM CONTACT

AREAS AND TIGHT SPACES IN CASE THE

COMPONENTS SHOULD SLIP AND CAUSE INJURY.

5. When the damaged area has been bent to the

desired position, slowly turn the release valve on

the pump in a counterclockwise direction to release

hydraulic pressure before removing the wedge.

MAINTENANCE

If the pump has been stored for long periods, check

the oil level before use. Stand the pump on a level

surface and remove the breather valve on the oil

reservoir. If necessary, top up via the breather valve

which is then screwed on finger tight.

Note: Only unscrew this when the system is not under

pressure. The oil level should be near the bottom of

the opening. If required, oil can be Topped. Top using

high quality Hydraulic Oil.

After extensive use, the hydraulic oil should be

replaced to ensure longer equipment life. Do not overfill,

or the piston rod will be unable to move freely. Replace

the breather valve after re-filling. The required oil

volumes are as follows.

24820 - 250 ml + 5ml

24821 - 500 ml + 5ml

STORAGE

After use, screw the valve cover on to the pump

to keep the connection clear of dust and dirt and

cover the hydraulic hose end with the plastic cap.

When not in use, the pump should be stored with

the release valve open. Store all the equipment in its

moulded case in a clean, dry environment protected

from the weather.

ENVIRONMENTAL PROTECTION

If disposing of old oil or any damaged components, do

not dispose of them with general waste. Any escaping

oil should be captured with some absorbent material

which should then be disposed of appropriately.

This product and its packaging contain valuable raw

materials and should be taken to your local civic

amenity site for recycling.

SPARE PARTS

In the event of lost or damaged components,

replacements are available from OEM Parts & Service.

Please refer to the following parts list and diagrams,

quoting the OEM part numbers:

4 Ton: 24820-01 to 69.

10 Ton: 24821-01 to 69.

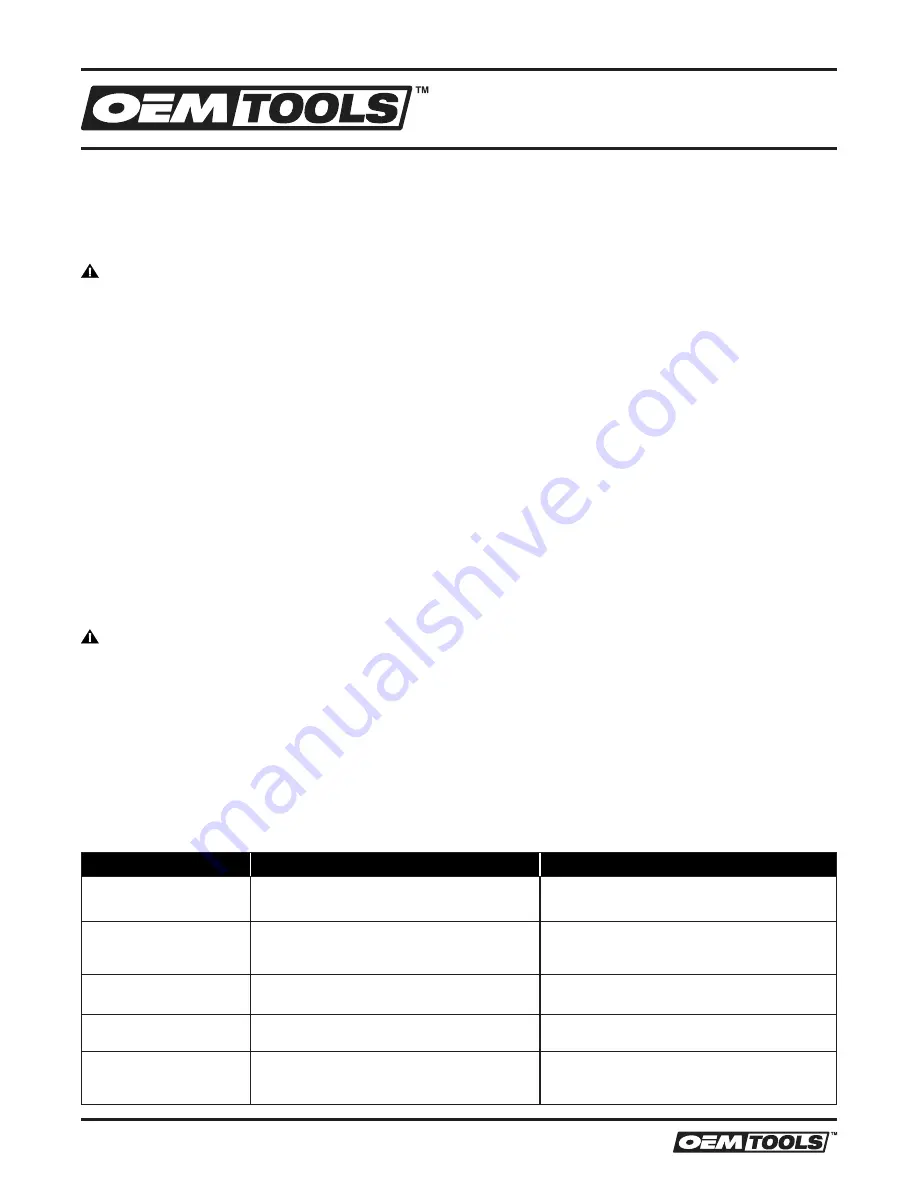

Problem

Possible Cause

Remedy

Ram does not operate

when handle is pumped.

Release valve not tightly closed. Air

trapped in system.

Firmly close the release valve. Purge air

from system by pumping operating handle.

Ram will not hold load.

Release valve not tightly closed.

Malfunction in pump such as dirt inside

valve mechanism.

Firmly close the release valve. Return

pump to dealer for overhaul.

Ram reluctant to lower

when load removed.

Oil reservoir overfilled. Piston binding.

Drain oil to correct level. Clean and

lubricate moving parts.

Ram will not extend to

full range of stroke.

Low oil level.

Add hydraulic oil to the reservoir.

Ram tries to tilt to

one side.

Poor positioning of the footing.

Stop work and re-position ram and base,

ensuring it is well supported and as close

to perpendicular to the repair as possible.

FAULT FINDING