Document UT-MT-0428

Page 20 of 35

Edition 11/03/2014

Supersedes edition 04/30/2012

INSET RUNWAY EDGE LIGHT SLRE

INSTRUCTION MANUAL FOR USE, INSTALLATION AND MAINTENANCE

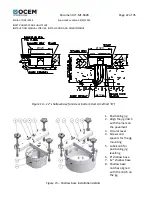

STEP A

B

ACTIVITY DESCRIPTION

7

Completely cover the bottom of the base with sealer material, apply a thin

coat of sealer to the bottom of the drilled hole to assure a bond between the

bottom of the light base and the drilled hole. It may be necessary to place

temporary plugs so as to block the wireways entrances into the drilled hole

(METHOD “A”) or the cable ducts entrance (METHOD “B”). The plugs will retain

the sealer while it begins to dry up.

ATTENTION: avoid starting the installation when the ambient temperature is

below 10°C (86°F), unless the sealer used is designed to dry up at a lower

temperature.

8

Push the base into the recess until its upper side is at the level of the

pavement surface; take care no sealer flowing inside the base. Align the notch

of the base with the markings on the pavement surface.

9

/

Observing the circular level fixed on the jig, level the jig by operating the three

leveling lobe knobs (Figure 15). If necessary, a weight may be placed on the jig

to hold the light base in position.

The remainder of the space between the sides of the shallow base and the

drilled hole should be filled with sealer up to approx 25 mm from the

pavement, according to the local needs.

Fill the remaining 25 mm with a suitable joint sealing filler.

10

/

Observing the circular level fixed on the jig, level the jig by operating the three

leveling lobe knobs (Figure ). If necessary, a weight may be placed on the jig to

hold the light base in position.

When the shallow base is in its final position, the conduit(s) must be properly

jointed to the hole(s) provided on the shallow base. This(these) hole(s) can be

provided either on the wall either on the bottom, the number and the

dimensions according to customer requirements (Figure 14).

The remainder of the space between the sides of the shallow base and the

drilled hole should be filled with sealer up to approx 25 mm from the

pavement, according to the local needs.

Fill the remaining 25 mm with a suitable joint sealing filler.

11

/

Lay the secondary power cable, equipped with a suitable two-pole receptacle

kit, and the grounding wire inside the cable duct.