TROUBLESHOOTING

S

If you require technical support for any Oceanic

Systems' products you can reach us using any of the

following ways:

•

Tel (UK): +44(0)1425 610022

•

Tel (USA): (844)898 6462

•

Fax: +44(0)1425 614794

•

Email: [email protected]

•

Web: www.osukl.com

•

Post: Oceanic Systems (UK) Ltd

Unit 11 Milton Business Centre

Wick Drive, New Milton, BH25 6RH

United Kingdom

WARRANTY

Oceanic Systems warrants this product to be free from defects in materials and workmanship for one year from

the date of original purchase. If within the applicable period any such products shall be proved to Oceanic

Systems satisfaction to fail to meet the above limited warranty, such products shall be repaired or replaced at

Oceanic Systems option. Purchaser's exclusive remedy and Oceanic Systems sole obligation hereunder, provided

product is returned pursuant to the return requirements below, shall be limited to the repair or replacement, at

Oceanic Systems option, of any product not meeting the above limited warranty and which is returned to Oceanic

Systems'; or if Oceanic Systems is unable to deliver a replacement that is free from defects in materials or

workmanship, Purchaser’s payment for such product will be refunded. Oceanic Systems assumes no liability

whatsoever for expenses of removing any defective product or part, or for installing the repaired product or part

or a replacement therefore or for any loss or damage to equipment in connection with which Oceanic Systems

products or parts shall be used. The foregoing warranties shall not apply with respect to products subjected to

negligence, misuse, misapplication, accident, damages by circumstances beyond Oceanic Systems control, to

improper installation, operation, maintenance, or storage, or to other than normal use or service.

THE FOREGOING WARRANTIES ARE EXPRESSLY IN LIEU OF AND EXCLUDES ALL OTHER EXPRESS OR IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND OF FITNESS

FOR A PARTICULAR PURPOSE.

TECHNICAL SUPPORT

NMEA2000®

Check that the unit is connected to the

NMEA2000®

network

securely and that the network is powered correctly.

PLC:

Check that the three connections to the connecting block are correctly and

securely fastened. Check that there is a 12 or 24 power feed connected.

NMEA2000®

There is no tank data on the network that matches the 5250 tank

type and device instance switch position.

Troubleshooting Procedure

Symptom

“NO INPUT” displayed

No display

Level does not reach 0%

in analogue mode

Ensure that the signal voltage reaches 0v for the sense input.

Do not attempt to

use an external pull-down resistor

, as this will affect the internal calibration

circuitry of the device.

2 of 4

3 of 4

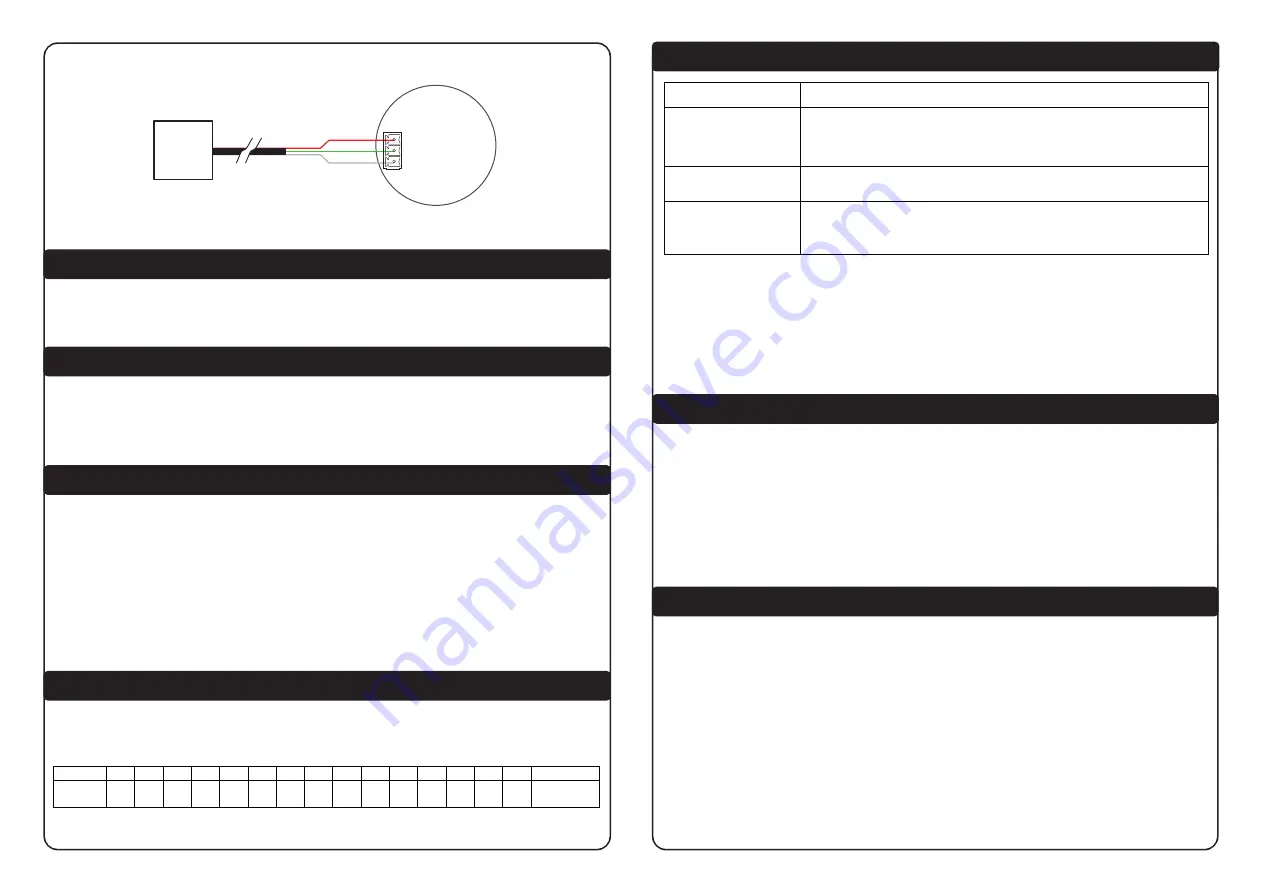

Signal

0-10V = 100%

+12/24V

Ground

PLC

PLC network example

SAFETY INSTRUCTIONS

This unit should only be installed by a person competent and experienced in working on electrical systems on

boats. Before beginning the work the battery should be disconnected to avoid the risk of a short circuit, fire or

explosion. Before drilling any holes to mount the unit or run the cabling always make sure it is safe to do so.

INCLUDED IN THE BOX

• 5250 Deck Gauge

•Instalation and Operation Instructions (this document)

•3x M4 30mm countersunk screws

•3 x M4 nuts

•3 x M4 flat washers

LOCATION AND INSTALLATION

The 5250 Deck Gauge should be mounted horizontally or vertically near the tank filler cap, so that it can be seen

easily during the tank filling operation. Supplied in the box is a full size mounting template showing the external

dimensions, the mounting hole sizes and their positions to simplify mounting. The three mounting holes in the bezel

are designed to fit suitable M4 countersunk or self-tapping screws.

To connect to the NMEA2000® network use a NMEA2000® drop cable to connect from the male M12 plug on the rear

of the unit to the nearest Tee connector.

To connect to a voltage feed from a PLC system or similar connect a three core cable from the connector block on

the rear of the unit to the voltage source as follows:

(Illustration of the rear of the unit showing three core cable connected to the connecting block to ground, +12/24

Volts and signal from 0-10 Volts)

Please note that the unit must be connected to

EITHER

the NMEA2000® network OR the PLC source.

DO NOT

CONNECT

the unit to both sources at the same time.

CALIBRATION AND SETUP

No calibration is required. Simply set the small rotary switch to the tank instance of the tank to be monitored in

the table below or set to ‘F’ if the unit is to be used with a PLC input and it will automatically display the tank

level percentage.

Switch

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Instance

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PLC

Mode