7.3.4.3 Replacing the transfer corotron (torn wire) (pinfed)

A29246-X20-X-4-7680 / fa702_pinfed.fm

277

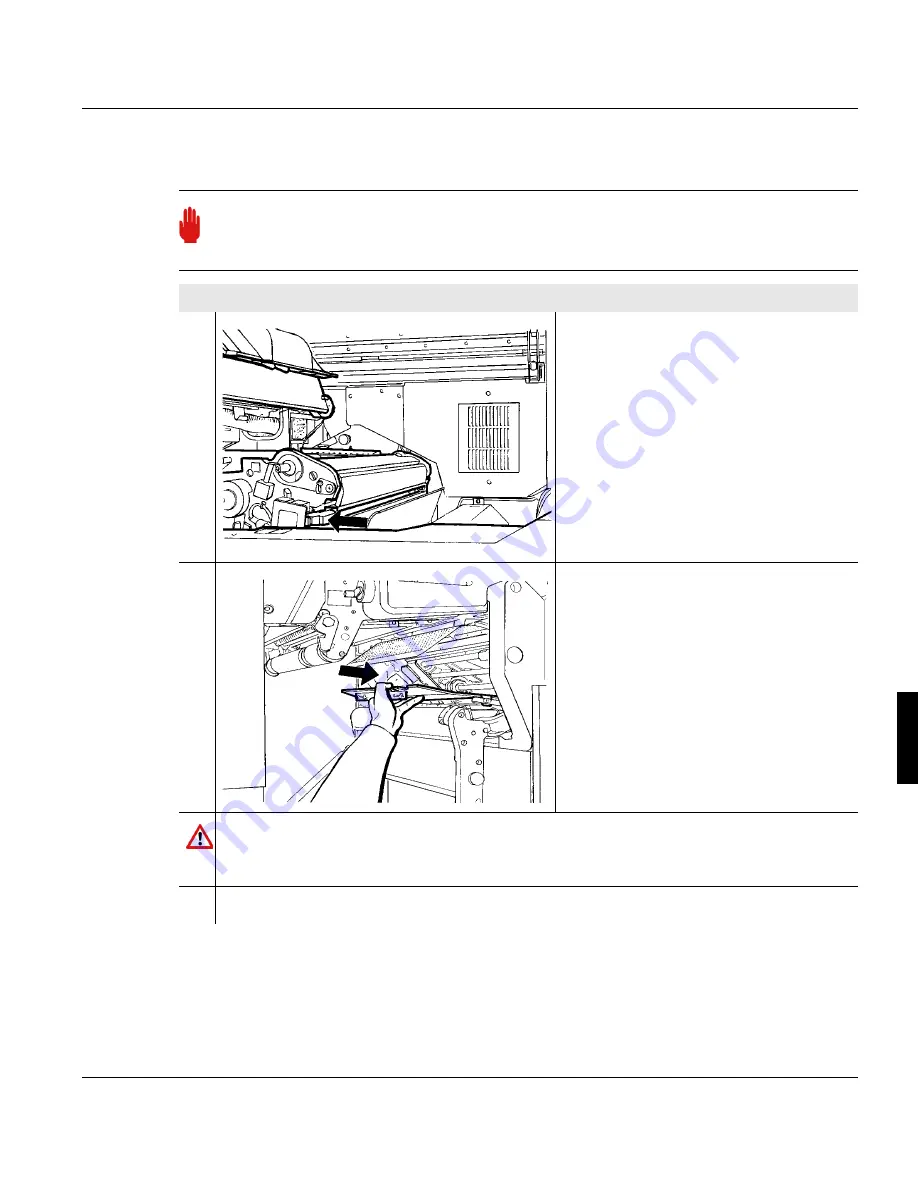

Install new transfer corotron

7.3.4.8 Complete corotron replacement >>> page 290

Important

Observe the safety directives before replacing corotrons (

see section 7.3.4 Replacing

corotrons, page 269)

.

Proceed as follows:

1.

Push in new corotron cartridge until the

spring engages.

2.

Swivel down the paper transporter by

the handle to the stop point and hold

firmly. At the same time, raise the

locking lever with your thumb to the

point where it jumps back to its exit

position.

Caution

Danger of pinching when swiveling the paper transporter back.

Always swivel the paper transporter back slowly and carefully.

3.

Swivel the paper transporter back again.

Summary of Contents for VarioStream 7000 SINGLE

Page 1: ...Oc Oc Operating Manual Oc VarioStream 7000 SINGLE Pinfed...

Page 4: ......

Page 24: ...1 8 Statutory requirements 24 A29246 X20 X 4 7680 all103 fm...

Page 58: ...3 5 Paper feed options 58 A29246 X20 X 4 7680 fa301 fm...

Page 208: ...6 8 1 Cleaning the toner mark sensor 208 A29246 X20 X 4 7680 fa603 fm...

Page 354: ...8 6 Permitting or blocking remote access 354 A29246 X20 X 4 7680 fa805 fm...

Page 373: ...Technical data A29246 X20 X 4 7680 faA01 fm 373 Weight Approx 1 260 kg simplex printing system...

Page 374: ...Technical data 374 A29246 X20 X 4 7680 faA01 fm...

Page 384: ......