CS9200 Low Solvent series printers

42

AP-40301 – Rev. 2.0 – 02/05/2008

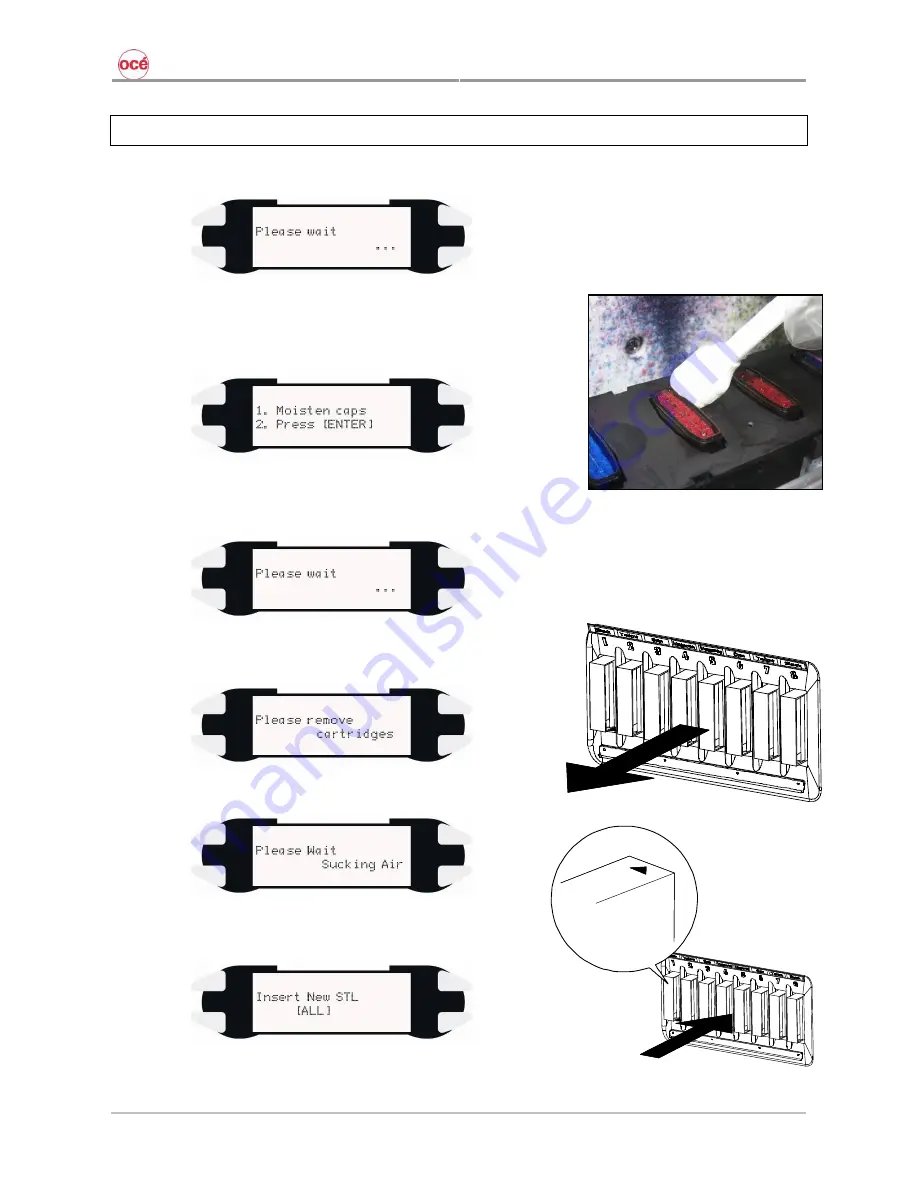

6.2 FIRST INK LOAD PROCEDURE

Step 1 :

Power ON the unit.

Step 2 :

The carriage will automatically move to the left side of the

machine. Open the front cover and moisten the rubber sides

of the caps with

Solvent Cleaning liquid

when asked. This to

optimize the ink loading cycle.

Step 3 :

Close the front cover when done and press the [ENTER] key.

Step 4 :

Please wait.

Step 5 :

Remove

dummy cassettes

when following message is

displayed.

Step 6 :

Please wait while printer is sucking air.

Step 7 :

Insert 8 NEW cassettes with

Low Solvent Setup

Cleaning

when following message is displayed.

Summary of Contents for CS9265

Page 1: ...Oc CS9265 Oc CS9290 Installation Guide Low Solvent...

Page 2: ...CS9200 Low Solvent series printers 2 AP 40301 Rev 2 0 02 05 2008...

Page 4: ...CS9200 Low Solvent series printers 4 AP 40301 Rev 2 0 02 05 2008...

Page 8: ...CS9200 Low Solvent series printers 8 AP 40301 Rev 2 0 02 05 2008...

Page 12: ...CS9200 Low Solvent series printers 12 AP 40301 Rev 2 0 02 05 2008...

Page 20: ...CS9200 Low Solvent series printers 20 AP 40301 Rev 2 0 02 05 2008...

Page 40: ...CS9200 Low Solvent series printers 40 AP 40301 Rev 2 0 02 05 2008...

Page 46: ...CS9200 Low Solvent series printers 46 AP 40301 Rev 2 0 02 05 2008...