6

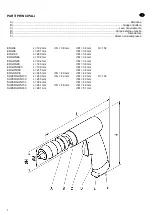

TECHNICAL FEATURES

GB

Table 1

Model

Code N°

Speed

Power

Steel

Consumption Weight

Chuck

Noise

Vibrations

drilling

standard

(dB(A))

(m/s

2

)

(rpm)

(watt)

(mm)

(Nl/min.)

(Kg)

Lp

a

h

ERG66

8201071

2800

150

6

450

0.90

3710645

75.8

<2.5

ERG88

8201072

1100

150

8

450

1.05

3710844

75.8

<2.5

ERG100

8201073

600

150

10

450

1.15

3711045

75.8

<2.5

ERGON66

8201081

4000

300

6

650

1.06

3710844

73.5

<2.5

ERGON88

8201082

2300

300

8

650

0.95

3710844

73.5

<2.5

ERGON8C

8201086

2300

300

10

650

0.80

3711035

73.5

<2.5

ERGON100V

8201089

2300

300

10

650

1.05

3711045

73.5

<2.5

ERGON100

8201083

950

300

10

650

1.20

3711045

73.5

<2.5

ERGON130

8201084

580

300

13

650

1.45

3711316

73.5

<2.5

SUPERGON13C

8201085

2100

480

13

720

1.54

3711316

76.3

<2.5

SUPERGON13V

8201088

820

480

13

720

1.72

3711316

76.3

<2.5

SUPERGON13L

8201090

240

480

13

720

1.72

3716317

76.3

<2.5

SUPERGON130

8201091

500

480

13

720

2.00

3711316

76.3

<2.5

SUPERGON160

8201092

400

480

16

720

2.65

3711616

76.3

<2.5

Air inlet 1/4” GAS - Ø inside tube min. ERG 6 mm; ERGON 8 mm; SUPERGON 10 mm. – Chuck connection:

ERG/ERGON 3/8”x24; ERGON130/SUPERGON 1/2”x20

Noise emission levels determined by using ISO/CD 15744

– ISO 3477

Levels of vibrations at the handle determined by using ISO 8662

Note: make sure that the performance features required correspond to those described above, otherwise it will be

necessary to choose a different model from the broad range offered by OBER.

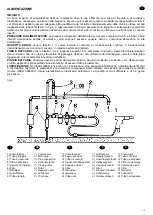

TOOL NOISE

The table of technical specifications indicates the noise level- where the noise level exceeds 85 dB (A) the noise power is

also indicated. Ear protectors must be worn where the noise level exceeds 85 dB (A) at the operator position. We

recommend that you also wear ear protectors below this noise level.

Noise risk and hearing damage are related to the intensity of the noise source and the length of exposure. Noise risk must

be assessed on a case by case basis taking into account these two factors. Measures should be taken to protect the user

against hearing damage in accordance with current Health and Safety regulations.

The formula and table can be used to calculate the daily exposure level for a drill using the use coefficient c. The use

coefficient c for screwdrivers is between 20 and 50%.

L

eq,d

= L

eq

+ 10 Log

10

T

e

/ T

0

TOOL VIBRATION

The table of technical specifications indicates the vibration level for the tool; the vibration level is calculated as the squared

weighted value of the acceleration frequency, Vibration risk is related to the intensity of the vibration source and the length

of exposure. Vibration risk must be assessed an a case by case basis taking into account these two factors. Measures

should be taken to protect the user against vibration injury in accordance with current Health and Safety Regulations.

The formula and table can be used to calculate the daily exposure level for a drill using the use coefficient c. The use

coefficient c for screwdrivers is between 20 and 50%.

5

,

0

8

,

8

t

a

a

h

h

h

Te= c T

0

T

0

= 8h

Daily exposure

level

L

eq

c

L

eq,

d

85

20%

35%

50%

78,0

80,4

82,0

t = c 8h

Daily exposure

level

a

h

c

a

h,8h

2,5

20%

35%

50%

1,1

1,5

1,8