12

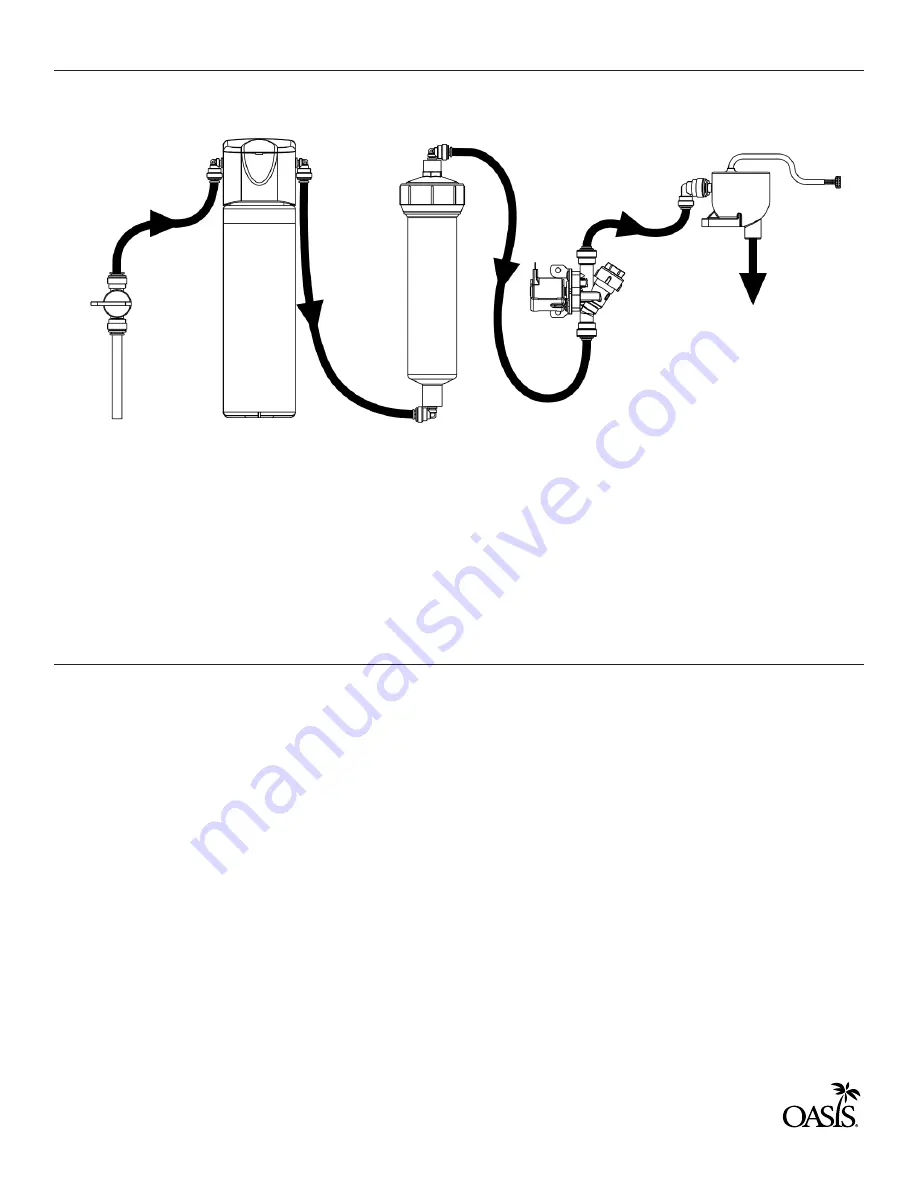

STEP 3B: FILTER INSTALLATION (WITHOUT CHILLER)

STEP 4: Electrical Connections

A.

B.

C.

A.

B.

C.

D.

Plumbing rough-in and wall opening should be prepared as shown in the rough-in

drawing. This drinking water cooler is designed to be operated at a water supply line

pressure of up to 100 PSI (690 kPa). A pressure regulator must be installed in front of the

unit’s water inlet if the pressure (including any possible pressure spikes) could exceed 100

PSI (690 kPa).

Install provided 3/8” O.D. copper tube, strainer, ball valve, and reducer to the building

water supply.

Install tubing as shown above.

A 2 x 4 junction box is provided for the installation of 115V receptacle. This unit is

intended to be connected to a ground fault circuit interrupting (GFCI) device to meet UL

requirements. It is recommended that a flexible conduit be used to supply power to the

junction box and chiller if used. Check the electric current available. Type and voltage

must be the same as listed on the product data plate.

As you put the bottle filler panel assembly in place on the frame assembly, feed the long

green ground wire and the terminals on the power supply cord through the bushings in

the frame assembly.

Attach the long green ground wire to the frame assembly junction box ground then plug

in the bottle filler power cord.

IMPORTANT: Review page 4: QUASAR UV-C LED Operation before proceeding. Failure

to follow the instructions on page 4 can damage the QUASAR module.

Optional In-Line

Filter

Optional

Versafilter III

Inlet Ball Valve

Assy. with

Strainer

Solenoid

Valve

UV-C LED

Summary of Contents for MWEBQ

Page 21: ...21...