- 7 -

4.5

TDS and Conductivity

4.5.1.

TDS and conductivity are linear related. The conversion factor is 0.40-1.00. Adjust the factor from

parameter P2.6. The factory default setting is 0.71 and please refer to Section 7.4. The meter only needs to

be calibrated in Conductivity mode, then after calibration of conductivity, the meter can switch from conductivity

to TDS.

4.5.2.

Adjust TDS conversion factor in parameter setting P4 according to the data collected during testing and

experience. Table – 10 lists some commonly used Conductivity and TDS conversion factors. This is for your

reference only.

Table – 10 Conductivity and TDS conversion factors

Conductivity of solution

TDS conversion factor

0-100 μS/cm

0.60

100-1,000 μS/cm

0.71

1-10 mS/cm

0.81

10-100 mS/cm

0.94

4.6

Sample Test

4.6.1.

Rinse conductivity electrode in distilled or pure water, dry it, and submerge it in the sample solution. Stir

the solution briefly and allow it to stay in the sample solution until a stable reading is reached and

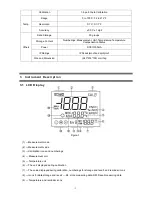

icon

appears on LCD, then get the reading value, which is the conductivity value of the solution.

4.6.2.

During the process of calibration and measurement, the meter has self-diagnosis functions, indicating

the relative information as below: Table – 8.

Table – 8 Self-diagnosis information of conductivity measurement mode

Display Icons

Contents

Checking

Wrong conductivity calibration solution or

the meter recognition of calibration

solution is out of range.

1. Check whether conductivity calibration

solution is correct.

2. Check whether the meter connects the

electrode well.

3. Check whether the electrode is damaged.

Press

key when measuring value is

not stable during calibration.

Press

key

after

icon appears.

During calibration, the measuring value

being unstable for over 3 minutes.

1. Shake the electrode to eliminate bubbles in

electrode head.

2. Replace with new conductivity electrode.

4.6.3.

Factory default setting

For factory default setting, please refer to parameter setting P7 (Section 4.7.2). With this function, all calibration

data is deleted, and the meter restores to the theory value. Some functions restore to the original value. When

calibration or measurement fails, please restore the meter to factory default setting and then perform re-

calibration or measurement. Please note once set the factory default, all the data deleted will be irretrievable.