Instruction Manual

CON 11/110

74

18

CALCULATING TEMPERATURE COEFFICIENTS

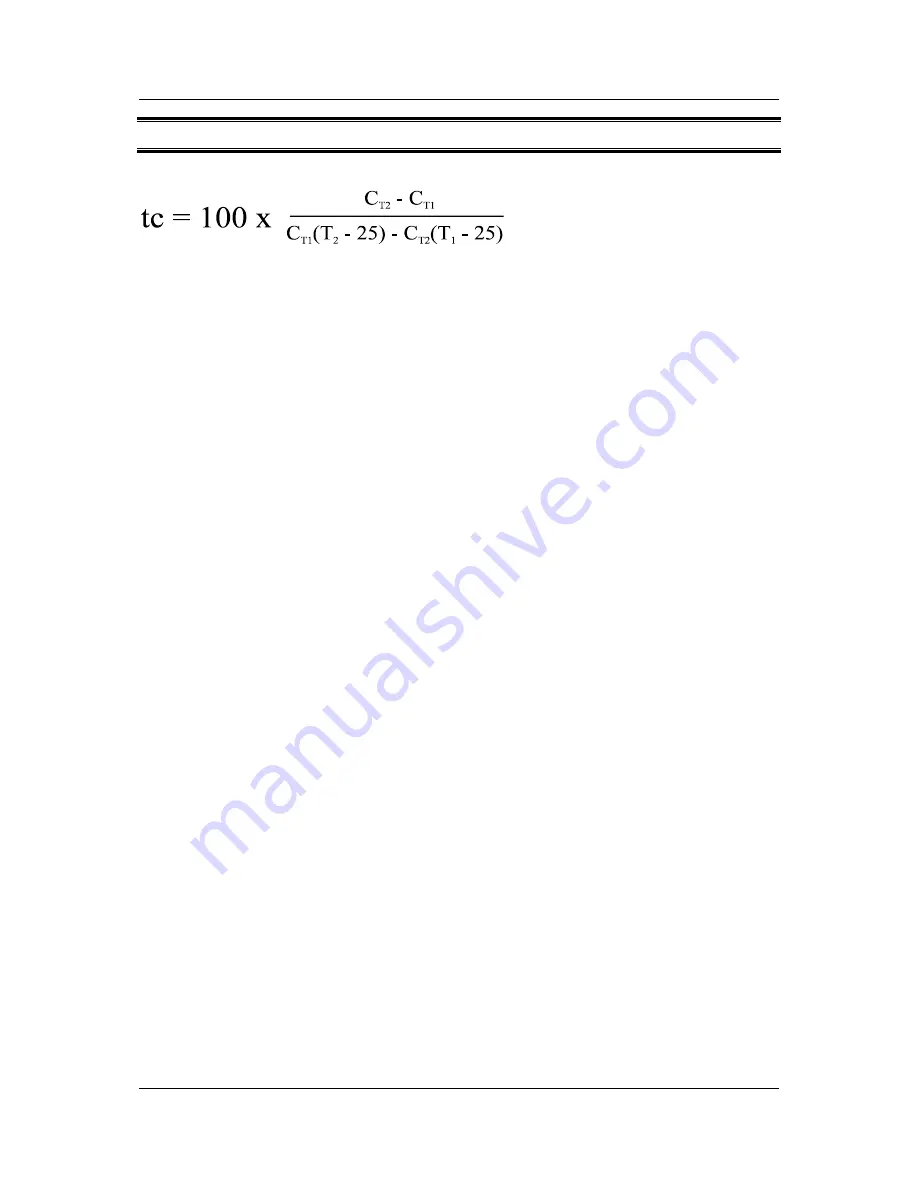

To determine the temperature coefficient of your sample solution use this formula:

Where:

tc

= Temperature coefficient

25

= 25 °C

C

T1

= Conductivity at Temp 1

C

T2

= Conductivity at Temp 2

T

1

= Temp 1

T

2

= Temp 2

NOTE:

A controlled temperature water bath is ideal for this procedure

1. Immerse the electrode into a sample of your solution and adjust the temperature

coefficient to 0% (that is, no compensation) by performing the following:

2. From measurement mode, press the

SETUP

key to enter Setup menu.

3. Press the

MI/

S

or

MR/

T

key until the lower display reads P7.0.

4. Press the

HOLD/ENTER

key to display the temperature coefficient value.

5. Press the

MR/

T

key until the upper display shows 0.0.

6. Press

HOLD

/

ENTER

key to confirm the value.

7. Press

CAL/MEAS

key to return to measurement mode.

8. Wait for 5 minutes. Note

T

1

and

C

T1

(conductivity at

T

1

).

9. Condition the sample solution and electrode to a temperature (

T

2

) that is about 5

°C to 10 °C different from

T

1

, and note the conductivity reading

C

T2

.

NOTE:

Record your results for future reference. Ideally

T

1

and

T

2

should bracket your

measurement temperature, and should not differ by more than 5 °C.

10. Calculate the temperature coefficient of your solution using the formula shown

above.

11. Enter the temperature coefficient you calculated into the meter by following the

following steps.

12. From measurement mode, press the

SETUP

key to enter Setup mode.

13. Press the

MR/

T

key until the lower display reads P7.0.

14. Press the

HOLD/ENTER

key to show the temperature coefficient value (should be

0, as per step 1 above).

15. Press the

MI/

S

key until the upper display shows your calculated temperature

coefficient.

16. Press

HOLD

/

ENTER

key to confirm the value.

17. Press

CAL/MEAS

key twice to return to measurement mode.

The calculated temperature coefficient will not be applied to all the meter readings.