12

Since the FS-70 ULTIMATE

is intended to be started with an

electric starter, the addition of a spinner assembly for

centering the starter sleeve is desirable. In this case, optional

locknut sets are available from O.S. Propeller Locknut Set for

Spinner (Code No. 45810200) Propeller Locknut Set for Tru

Turn Spinner (Code No. 45810300).

PROPELLER & SPINNER ATTACHMENT

Ream the propeller shaft hole to 6.5mm bore with an

appropriate reamer, checking that the hole is exactly

centered.

Install the prop to the engine shaft, followed by the retaining

washer and prop nut and tighten firmly with a 12mm

wrench.

There is a risk, particularly

with powerful four-stroke

engines, of the propeller flying

off if the prop nut loosens due

to detonation ("knocking") in

the combustion chamber when

the engine is operated too

lean, or under an excessively

heavy load.

Obviously, this can be very hazardous. To eliminate such

dangers, the O.S. Safety Locknut Assembly was devised.

Install this as follows:

Lock Nut

Propeller Washer

Propeller Nut

1.

2.

3.

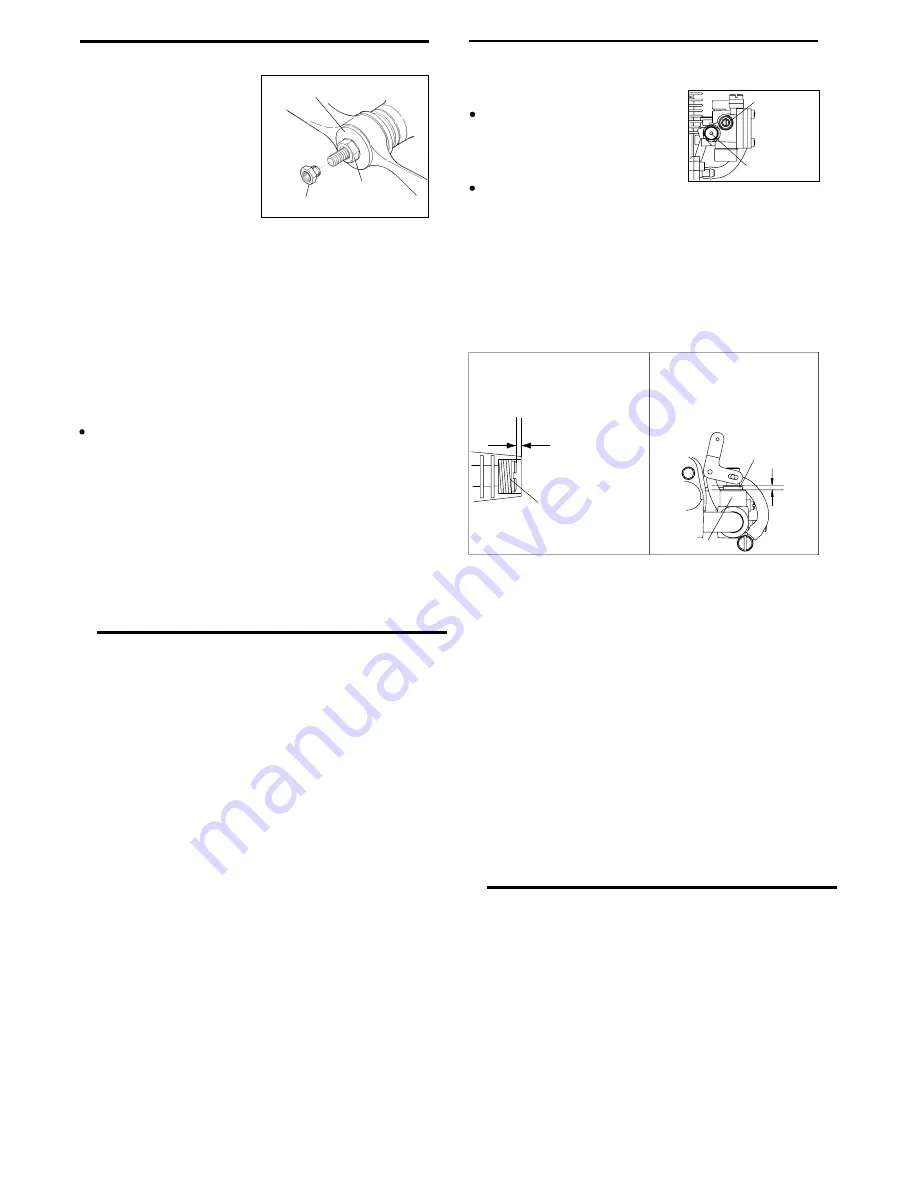

Two adjustable controls are provided on these carburetors.

They are as follows:

TYPE 60U CARBURETOR

The Needle Valve

This is used to establish the fuel/air

mixture strength required for full

power when the throttle is fully open.

The sequence in which these controls are adjusted is

explained in the succeeding sections, under Starting,

Running-in and Idling Adjustment.

Add the special tapered and slotted locknut and secure

with a 10mm wrench while holding the prop nut with the

12mm wrench.

Needle Valve

Mixture

Control Screw

Spinners retained by a nose bolt cannot be used with this

Locknut.

The Mixture Control Screw

This is used to establish the mixture strength required for

steady idling and a smooth transition to medium speeds.

(The varying mixture strength required between part-throttle

and full-throttle running is automatically adjusted by coupled

movement of the throttle.)

BASIC POSITION OF THE

MIXTURE CONTROL SCREW

The basic position is

1/2 turn screwed in

position from the flat

with the body face.

Mixture Control Screw

IDLING POSITION OF THE

THROTTLE VALVE

The idling position is where

the throttle valve comes out

approx. 1mm from the body

face.

Carburetor Body

Throttle Valve

Approx. 1mm

13

STARTING

The FS-70 ULTIMATE

is not equipped with manual choke

controls, as they are intended for use with an electric starter only.

A high-torque electric starter not only makes starting the engine

much easier, it dispenses with the need for a choke valve by

turning the engine over fast enough to cause the fuel pump to

prime the cylinder automatically.

Starting procedure is as follows:

Check that the current to the glowplug is switched off.

Check that the polarity of the starter battery leads rotates the

engine counter-clockwise when viewed from the front.

Open the needle-valve approx. 2 turns from the fully closed

position and temporarily set the throttle in the fully open

position.

Apply the starter and press the starter switch for 5-6

seconds, or until fuel is seen to emerge from the exhaust

outlet, indicating that the cylinder is now primed.

Close the throttle-arm to within 15-20

°

of the fully closed

position and slowly turn the prop "backwards" (clockwise) by

hand until it is arrested by compression.This is to enable the

kinetic energy of the prop to subsequently assist the starter

through the compression stroke to start the engine.

Energize the glowplug and apply the starter. If the starter

fails to rotate the engine completely, this may be due to the

cylinder being over-primed, or to the starter battery being

insufficiently charged.

RUNNING-IN ("Breaking-in")

For long life and peak performance, every engine needs

special treatment when new, known as "running-in" or

"breaking-in". This is a process during which the engine is

operated under strictly controlled conditions at the beginning

of its life, in order to avoid the risk of immediate damage to

certain components through becoming overheated or stressed

and to help working surfaces to become smoothed and

aligned for maximum mechanical efficiency thereafter.

With some engines, this can require a tediously protracted

period of bench running, but, as O.S. engines are

manufactured to fine tolerances and from the finest quality

materials, a relatively brief running-in period is sufficient and

can be completed with the engine installed in the aircraft.

The recommended procedure is as follows :

1.

2.

3.

4.

5.

6.

Check these conditions and, instead of pressing the starter

button after applying the starter, have the starter spinning

before applying it to the engine, to give it a "running start".

When the engine starts, slowly open the throttle, leaving

the needle-valve at its rich starting setting to promote cool

running conditions.

However, if the engine slows down because the mixture is

excessively rich, the needle-valve may be closed a little to

speed it up until it runs evenly.

Now disconnect current to the glowplug and gradually close

the needle-valve so that the engine rpm increases. Make

adjustments to the needle in small steps. Abrupt changes

at this stage are likely to cause the engine to stall. Restart

the engine by simply applying the starter with the glowplug

re-energized and the throttle at its starting setting.

7.

8.