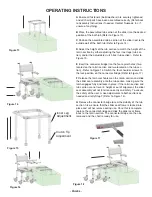

Figure 8

Reconfigure the multiCHAIR 6000Tilt, 6200Tilt,

6000Tilt P1, and 6000Tilt P2

with the Tub Section on

the user’s left side (Refer to Figures 6 and 7)

The roll-

in section and tub section frames are identical. To change

slide direction do the following:

A

Unbolt the sheet metal calf support plate using a large

Phillip head screw driver and a small Crescent wrench and

then reinstall it on the other frame.

B

Move the latch stops as shown using the 5/32” Allen

wrench that is provided with the slider

C

Move the complete leg assemblies and the side suction

cups from one frame to the other.

D

Relocated the tilt system crank handle from one side of

the shuttle frame to the other side

E

Adjustments to the “Tilt Assembly” (Refer to Figure 5 on

page 2 and Figure 7 this page) need to be made as fol-

lows: Remove the “crank handle” by removing the socket

screw with an 1/8” Allen wrench. Remove the cap from the

opposite side of the frame, again using an 1/8” Allen

wrench, and install it on this side. Reinstall the crank han-

dle on the opposite side of the frame. NOTE: position the

seat in the horizontal position and the crank handle should

be approximately covering the flat head socket bolt on the

frame.

F

Move the slider latch to the opposite side of the tilt

assembly:

1) Remove the 1/4-20 Flat Head Socket Screw with the

5/32 Allen wrench that is provided with the slider.

2) The second 1/4-20 Flat Head Socket Screw is bolted to

a nylon insert lock nut. Therefore a small crescent wrench

or a 7/16” open end can be used to hold the nut while turn-

ing the screw.

3) Position the latch on the opposite side of the frame and

reinstall.

Cantilever Arms

: If desired, the cantilever arms can be

removed from the backrest assembly for storage during

traveling. This can be accomplished by unscrewing the

socket head cap screws that attach the arms to the back-

rest posts using the 5/32” Allen wrench. Then remove the

arm assemblies from the posts and re-insert the socke

head cap screws into the arm assemblies, so they are not

lost. To re-install the cantilever arms, simply follow the

steps above in reverse (Refer to Figure 8).

ADDITIONAL ASSEMBLY INSTRUCTIONS

Figure 7

Release Latch Assembly: Do not attempt to unscrew the inner

slotted screws. Doing so can cause the entire latch assembly to

come apart, rendering it useless (There is no tool provided for this

operation) .

- PAGE 3 -

NOTE!

Figure 6

A

B

D

C

E

F