H

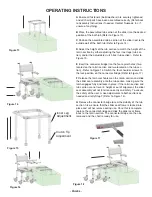

The calf support assembly is simply slide into the mounting

block (Refer to figure 3), and be adjusted by sliding it within the

mounting block than then pushing it down to engage one of the

bottom slots on the square tube.

I

Place the

connector bridge

into the matching holes on both

the roll-in section and tub section (Refer to Figure 3).

SAFETY PRECAUTION!

Both backrest posts must be completely engaged with the seat

frame and securely tightened. If they are not fitted correctly, there

is a risk of the posts dislodging from the seat frame.

This could cause serious injury or even death!

SAFETY PRECAUTION!

The swing-away footrests should be installed into the footrest

clamps after the user has been transferred into the chair. Putting

an extreme amount of weight on the swing-away footrests or

using them as an assistive device when transferring can cause

the entire chair to tip forward, resulting in serious injury or even

death!

SAFETY PRECAUTION!

The connector bridge must be fully seated into the corresponding

holes of both the roll-in section and tub section. If this is not done

correctly, the seat frame could dislodge itself from the chair when

transferring from the roll-in section to the tub section.

- PAGE 2 -

Figure 5

J

The shuttle frame is released from the roll-in base by pulling

back on the underside release lever and simultaneously sliding

the shuttle towards the tub section base (Refer to Figure 4).

K

The tilt mechanism is operated by pulling the spring loaded

crank lever outwards and rotating the handle. Once the tilt angle

is reached, we recommend either having the unit at its

highest/largest tilt angle or flat, slowly release the spring loaded

lever and it will automatically lock itself its pin into one of the

indexing holes on the indexing disk (Refer to Figure 4)

L

Index the handle by first positioning the seat in the horizontal

position. The end of the crank handle should be approximately

over the flat head socket bolt on the frame.

Figure 3

Figure 4

H

I

J

K

L