04/21/20

Page 5

Champion

®

RC300

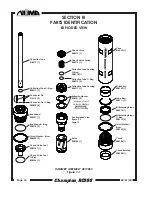

SECTION II

MAINTENANCE

DISASSEMBLY

•

Maintenance should be performed in a clean environment.

CAUTION

USE CAUTION WHEN HANDLING DOWN THE HOLE HAMMER PARTS. NUMA HAMMER

PARTS ARE MANUFACTURED FROM HARDENED, HEAT TREATED MATERIALS. DROPPING

OR STRIKING THESE PARTS MAY CAUSE SEVERE DAMAGE. STRIKING THE HAMMER

PARTS WITH HAMMERS, CROWBARS OR LIKE INSTRUMENTS WILL VOID THE WARRANTY.

•

Tools needed: hammer stand, 26" (660 mm) "J" or fork wrench (possibly incorporated in

the hammer stand), overhead crane or lift truck, pulldown visetong with a 28" (711 mm)

diameter capacity or a self contained power wrench capable of 200,000 foot pounds

of torque, lifting eyes, 2" (51 mm) diameter brass rod or mild steel rod 3 to 5 feet (1 m

to 1.5 m) long, snap ring pliers, chains, lifting slings, a drift pin and several difference

sized screwdrivers.

•

Clean the outside of the hammer. This will insure a good surface to clamp on.

•

With the hammer in a vertical position, remove the collection tube. The collection tube

is equipped with two 1/2" UNC threads for lifting eyes.

•

The collection tube can be replaced without disassembly of the hammer. Prior to

removal of the collection tube, pressure wash the inside diameter of the collection

tube to remove any cuttings or debris. The collection tube is equipped with two 1/2"

UNC tapped holes for lifting eyes to facilitate removal. With the hammer in a vertical

position, use an overhead crane or lift truck of appropriate capacity to remove the

collection tube. Thoroughly lubricate the collection tube O.D. and reverse the process

to install the new collection tube.

CAUTION

FAILURE TO THOROUGHLY CLEAN THE COLLECTION TUBE BEFORE REMOVAL MAY

ALLOW FOREIGN MATERIAL TO CONTAMINATE THE HAMMER.

•

Using an overhead crane or lift truck of appropriate capacity, place the hammer on a

hammer stand and secure it in the wrench. The chuck end can be held by the 26" (660

mm) flats, in the wrench. The backhead is also held in the 26" (660 mm) wrench. Place

the visetongs on the area of the case where the bit bearing is located when working

on the chuck end of the hammer. When working on the backhead end of the hammer,

place the chain vise on the area of the case where the feed tube housing in located.

Summary of Contents for Champion RC300

Page 2: ......