12

Installation and Maintenance

QUIETWIN QTR BELT DRIVE TWINFAN

Maintenance (continued).

CASE SIZE ‘D’ UNITS

ISOLATION

BEFORE COMMENCING WORK MAKE SURE

THAT THE UNIT AND NUAIRE CONTROL,

IF FITTED, ARE ELECTRICALLY ISOLATED FROM

THE MAINS SUPPLY.

Access to the unit internals is gained by removing the top

cover(s) Isolate the unit and inspect the following items three

months after commissioning and then once per year.

Maintenance Intervals

The first maintenance should be carried out three months

after commissioning and thereafter at twelve monthly inter-

vals. These intervals may need to be shortened if the unit is

operating in adverse environmental conditions, or in heavily

polluted air.

Motors

Brush away any dust or dirt from the motor housings and

ensure that the motor vents are unblocked.

Bearings

Lubrication is unnecessary as the motors are fitted with sealed

for life bearings.

Impellers

Remove any dust and check that the impellers are securely

fixed to the motor shafts. Take care not to disturb any balance

weights fitted. Check sealed for life bearings for excessive

wear.

Shutter Assembly

Remove any dust and check that the shutters operate freely.

and that they seal the appropriate fan outlet effectively.

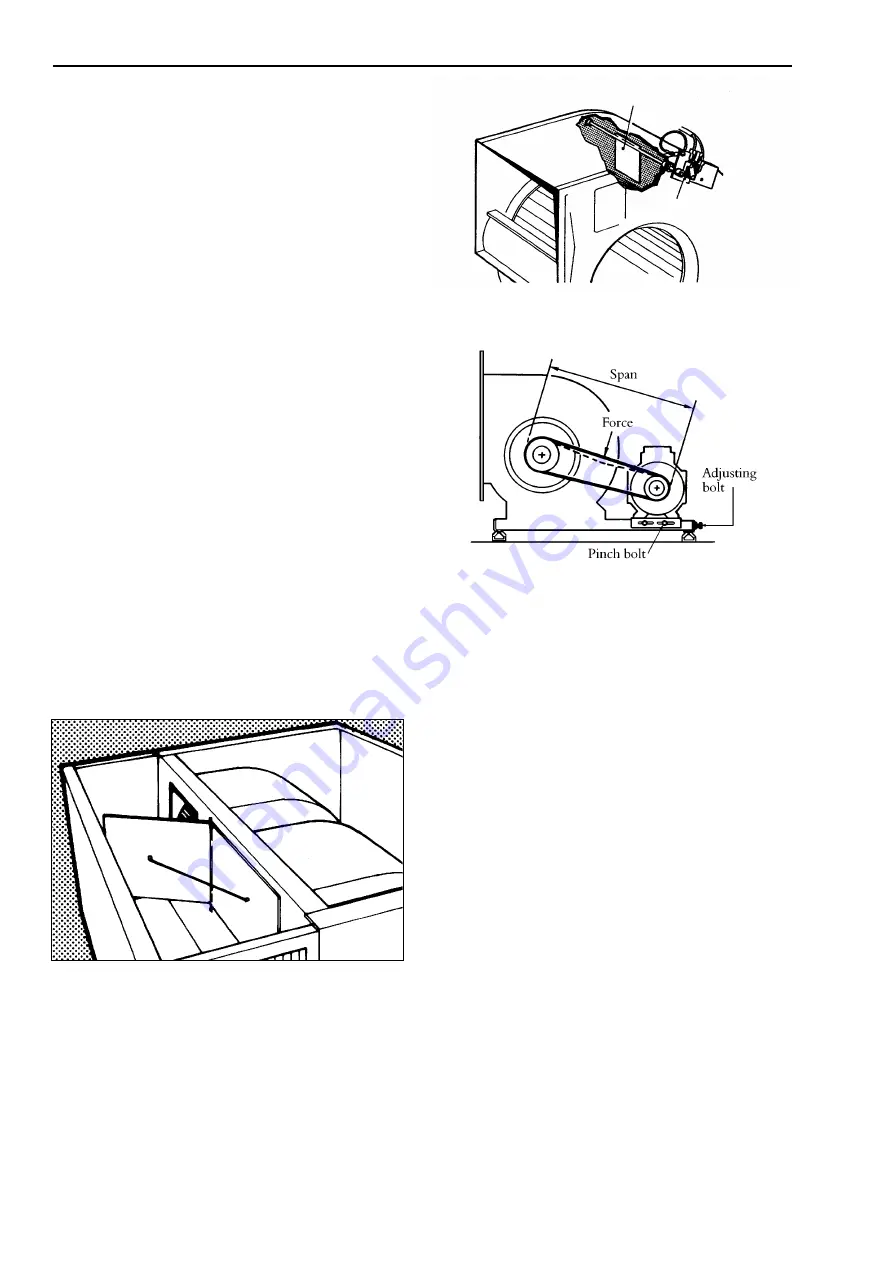

Fig. 13. Quietwin shutter detail.

Anti Vibration motor plate mountings

Each motor plate is supported on ten individual resilient

mountings. Check that all the mountings are secure and in

good condition. See fig 13.

Aiflow Flapswitch for Auto changeover

Check the flag switches operate freely by locating the spindle

and flap (through the blower outlet aperture) and carefully

moving the flap. A click will be heard when the switch oper-

ates. See fig. 14.

NOTE: Do not bend the flaps.

Fig. 14 Auto changeover flap switch

Fig. 15 Tensioning the drive belts on size ‘D’ units.

Belts

All belt drive units incorporate belt tensioning devices. To

adjust the belt tension, slacken the pinch bolt on the sides of

the motor plate. Turn the adjusting bolt clockwise to tighten

the belt and counter clockwise to loosen it.

The drive should be tensioned until a slight bow appears in

the slack side of the ‘V’ belt when running under load. To

check for correct tension, proceed as follows.

1. Measure the span length (See fig. 15).

2. At the centre of the span, apply a force at right angles to the

belt sufficient to deflect one belt 16mm for every metre of

span length (see fig. 7). The force required to deflect the ‘V’

belt should be from 0.5kg to 0.8kg.

General Cleaning and Inspection

Clean and inspect the exterior of the fan unit and associated

controls etc.

Remove the access panel from the fan unit. Inspect and, if

necessary, clean the fan and motor assemblies and the interior

of the case. If the unit is heavily soiled it may be more conve-

nient to remove the fan / motor assemblies.

If NuAire controls and or remote indicators are fitted, remove

the covers and carefully clean out the interiors as necessary.

Check for damage.

Check security of components. Refit the access covers.

General

1. Check that all fixings are tight.

2. Check sealing strips around the fan outlets are tight up

against the bulkhead.

3. Check that duct connections are not leaking.

Flap and spindle

Micro switch