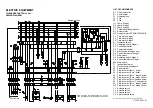

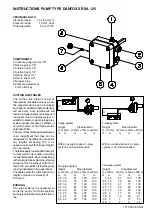

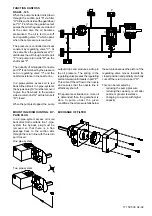

ELECTRIC EQUIPMENT

OIL BURNER CONTROL: LAL1...

WIRING DIAGRAM

LIST OF COMPONENTS

A1

Oil burner control

B1

Photoresistor

F1

Operating fuse

F2

Fuse

F3

Fuse

H1

Lamp, Stage 1

H2

Lamp, Stage 2

H3

Lamp, Stage 3

K1

Thermal overload protection

M1

Burner motor

M2

Damper motor L&S SQN75.436A21B

P1

Time meter, Stage 1

P2

Time meter, Stage 2

P3

Time meter, Stage 3

S1

Operating switch

S2

Operating switch, Stage 2

S3

Control thermostat

S4

Temperature limiter

S5

Micro switch for hinged door

S6

Control thermostat, Stage 2

S7

Main switch

S8

Operating switch, Stage 3

S9

Control thermostat, Stage 3

S20 Main switch

T1

Ignition transformer

X1

Connection terminal board

X2

Earth terminal

X3

Plug-in contact "Euro", burner

X4

Plug-in contact "Euro", boiler

X5

Plug-in contact "Euro", stage 3 burner

X6

Plug-in contact "Euro", stage 3 boiler

X7

Plug-in contact "Euro" 3-phase, burner

X8

Plug-in contact "Euro", 3-phase, boiler

X9

Plug-in contact "Euro", stage 2 burner

X10 Plug-in contact "Euro", stage 2 boiler

Y1

Solenoid valve 1

Y2

Solenoid valve 2

Y3

Solenoid valve 3

Y4

Safety solenoid valve

Mains connection and fuse in accordance with local regulations.

171 425 09 01-01

If S6 is missing connection between L1 and L2.

If S9 is missing connection between T6 and T8.

Damper position

3N ~50/60H

Z

400 V

Summary of Contents for MOL 1650-3R B70 2-3

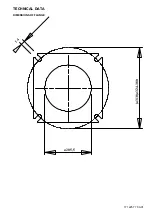

Page 4: ...TECHNICAL DATA DIMENSIONS OF FLANGE 171 225 77 00 01 14 310 324 380 205 5...

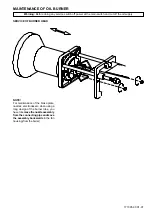

Page 14: ......

Page 16: ...NOTES...

Page 17: ...NOTES...