8

E

.0

4.

20

00

•

G

. 1

6.

11

.1

0

Adjustment table

Measuring the photocurrent (MZ 770S only)

To measure the photocurrent, disconnect the plug unit

from the flame failure controller and install the pair of

measuring cables* between the plug and socket unit.

Both measuring connections should be connected to

the measuring instrument. If there is a negative deflec-

tion of the measuring instrument, reverse the plug on

the measuring instrument lead ! Set the measuring in-

strument to ampere metering for DC, measuring range

up to approx. 200

µ

mA !

Recommended measuring accessories

Digital measuring instrument

Art. No. 59-20-50263

* Pair of measuring cables

for photocurrent

Art. No. 59-20-50408

16. Adjustment table

The values given in the table are only setting values for start-up. The system settings required

in each case must be redefined if values such as boiler output, calorific value and altitude deviate.

Adjustment is required in any case (due to the system design).

•

For initial start-up, fill the burner tank up to the oil mark by hand.

Caution !

If the oil level is too high, the float switch will switch off the burner.

If the oil level is too low, the heating cartridge will become encrusted or damaged.

Adjustment table for rapeseed oil

Adjustment table for fuel oil

The thermostat on the burner tank must be set to between "min." for heating oil EL and 140°C

for rapeseed oil, depending on the viscosity of the oil.

Burner type

G100

Output in kW

65

70

78

82

90

96

102

Oil throughput in kg/h

6.4

7.0

7.7

8.1

8.9

9.5

10.1

Primary air in bar

0.5

0.6

0.7

0.8

1.0

1.2

1.5

Secondary air

(scale on air damper)

3.0

3.5

3.8

4.0

4.5

5.0

6.0

Thermostat setting in °C

140

Burner type

G100

Output in kW

71

82

91

100

117

123

133

Oil throughput in kg/h

5.9

6.9

7.6

8.4

9.8

10.3

11.1

Primary air in bar

0.4

0.5

0.6

0.8

1.0

1.2

1.5

Secondary air

(scale on air damper)

3.2

3.8

4.0

4.8

6.2

6.5

7.0

Thermostat setting in °C

0° do not heat

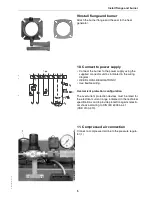

Flame failure controller

Control unit

bottom part

500

µ

A

or

200

µ

A

Summary of Contents for G100 Universal

Page 1: ...G100 Universal Oil Burner Installation Maintenance Manual...

Page 15: ......