4

E

.0

4.

20

00

•

G

. 1

6.

11

.1

0

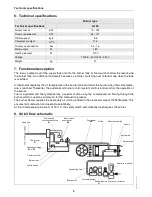

Technical specifications

6. Technical specifications

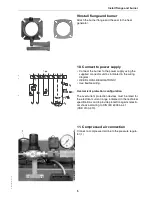

7. Functional description

The fuel is pumped out of the supply tank and into the burner tank. A float switch controls the level inside

the burner tank. An additional microswitch serves as a limiter, switching over to fault mode when the tank

is overfilled.

A thermostat regulates the oil temperature in the burner tank and starts the burner when the set tempera-

ture is reached. Thereafter, the automatic oil burner control system controls and monitors the operation of

the burner.

Fuel is aspirated and finely atomised by a special nozzle using the compressed air flowing through the

burner, which is used as primary air for the combustion process.

The burner blower supplies the secondary air which is added to the atomised spray at the baffle plate. This

ensures full combustion and operational reliability.

At the oil temperature in excess of 150° C, the safety switch automatically de-energises the burner.

8. Air/oil flow schematic

Burner type

Technical specifications

G100

Output, fuel oil

KW

70 - 132

Output, rapeseed oil

KW

65 - 101

Oil throughput

kg/h

8.6

Compressor output

m

3

/h

11.5

Primary air connection

bar

0.4 - 1.5

Motor output

W

180

Heating element

W

1100

Voltage

1/N/PE ~50 Hz 220 - 240 V

Weight

kg

21

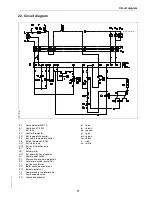

Feed line

Contact switch

Heating cartridge

E1 + E2

Overflow tank

Burner tank

Thermostat

F1

Safety valve

Pressure gauge

Solenoid valve

Y1

Primary air actuator

Pressure controller

Connecting line

baffle plate

Burner pipe

Nozzle

Nozzle assembly

Oil line

Fan wheel

M1

Micro-switch,

overflow protection

S1

Micro-switch,

level control

S2

Summary of Contents for G100 Universal

Page 1: ...G100 Universal Oil Burner Installation Maintenance Manual...

Page 15: ......