Boiler and Heating System Piping

│

FTV I&O Manual

38

Dirt Removal

– A dirt removal device should be installed in all systems. In older systems containing cast iron

radiators/baseboard or large amount black iron or steel pipe, a magnetic dirt separator must be installed.

Glycol, Snow Melt, and Oxygen Permeable Piping

– When freeze protection is required, only multi metal

inhibited propylene glycol, at a minimum of 20% and a maximum of 50%, is allowed for use with boiler

system. If the boiler is being used with a snow melt system that requires a concentration of glycol higher

than 50%, then a plate heat exchanger is required to separate the snow melt system from the boiler water.

Note: the use of glycol may reduce the usable output capacity of the boiler, thus requiring the unit to be

“down-fired” by limiting the maximum operating capacity and/or the maximum water temperature. If

oxygen permeable piping (non-oxygen barrier tubing) is used in the system a plate heat exchanger is required

to separate it from the boiler water.

Ethylene glycol is prohibited for use with the boiler, only inhibited propylene glycol is

allowed for use with the boiler.

Water Treatment

– When filling the boiler system, the water must be tested. Table 10-1 outlines the

parameters that should be tested for, and the corresponding ranges that are permitted. Water quality that does

not fall within the stated ranges will void the warranty of the boiler. Utilize proper testing equipment, such as

digital meters, to verify water quality.

Never use petroleum based compounds in the system for cleaning or sealing.

Inhibitors should be used for all installations in both new and existing heating systems. Follow the

instructions provided by the inhibitor manufacturer when adding to the system to ensure the correct

concentration. A list of approved inhibitors is provided below.

•

Rhomar Pro-tek 922

•

Sentinel X100

•

Fernox Protector F1 (NTI part no. 83448)

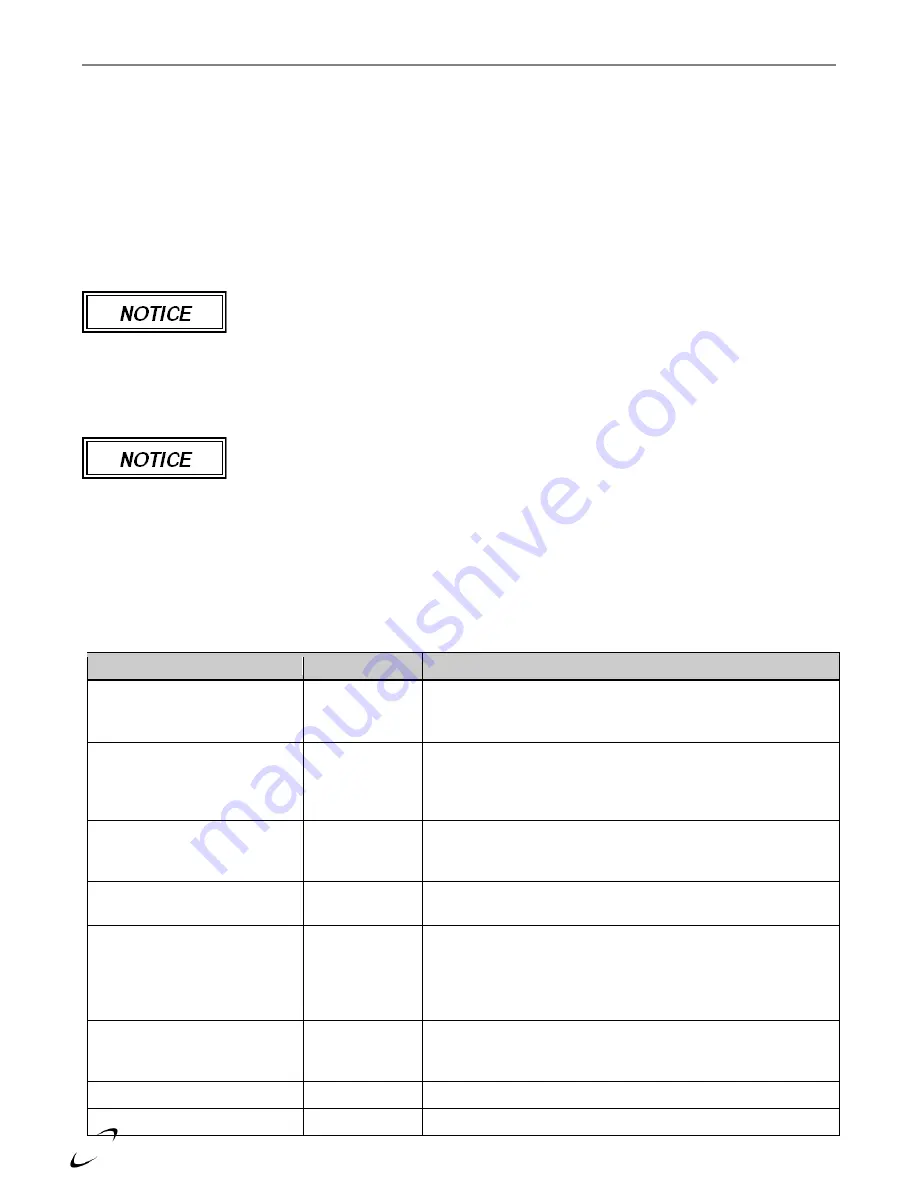

Table 10-1 Boiler System Cleansers and Corrosion Inhibitors

Parameter

Range

Information

pH

7 to 9

The total pH scale ranges from 1 to 14, with 7 considered to

be neutral. A pH less than 7 is said to be acidic and solutions

with a pH greater than 7 are basic or alkaline.

Conductivity

100 to 300 μS/cm

Conductivity is an indirect method of determining the total

dissolved solids in the water. High conductivity in

untreated

water indicates hard water. Adding corrosion inhibitors will

increase conductivity.

Hardness

50 to 200 ppm

(3 to 11.7 gpg)

Artificially soft water can damage the system. The use of un-

softened water is recommended. Do

not

use distilled or

purified water.

Chlorine

150 ppm

High Chlorine content in the water can damage the boilers

heat exchanger.

Glycol (if applicable)

20-50%

Concentrations below 20% can promote bacteria growth, and

concentrations above 50% will dramatically reduce

efficiency and may require de-rating the boiler. Inhibited

glycol mixed at 50% should have a pH 8-9. Check with

glycol manufacturer.

Total Dissolved Solids (TDS)

50 to 300 ppm

TDS includes calcium and magnesium associated with lime scale

but also includes other harmful solids such as magnetite, chlorides,

sodium and other organic and inorganic materials.

Bacteria/Mold

none

Glycol above 20% will kill any bacteria.

Molybdate Corrosion Inhibitor

100 to 300 ppm

Film-forming inhibitor that protects against iron corrosion.