N1040 Controller

NOVUS AUTOMATION

2/7

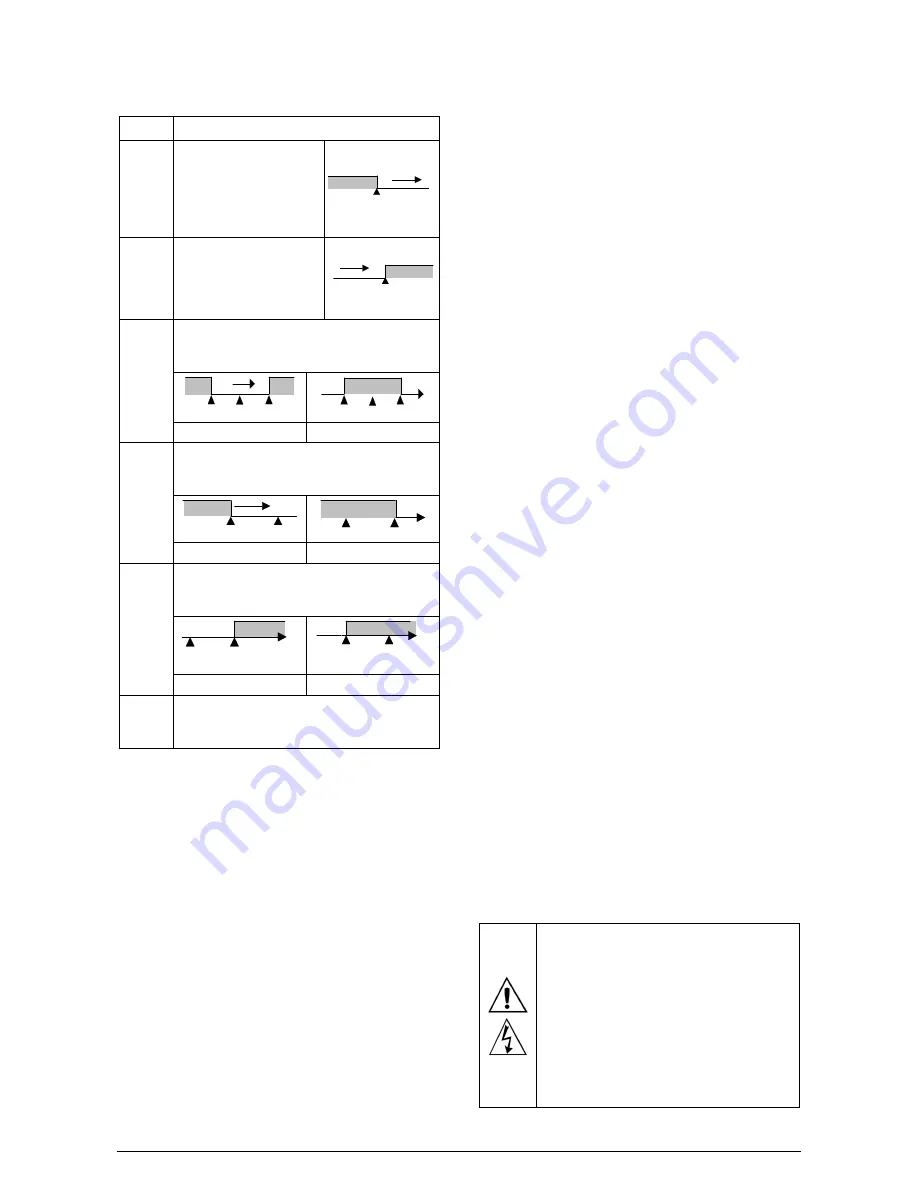

ALARM OUTPUT

The controller contains 2 alarms that can be directed (assigned) to any

output channel. The alarm functions are described in Table 02.

off

Output is not used as alarm.

lo

Alarm of Absolute Minimum

Value. Triggers when the

value of measured PV is

below the value defined for

alarm

Setpoint

.

(SPA1 or

SPA2)

.

SPA1

PV

ki

Alarm of Absolute Maximum

Value. Triggers when the

value of measured PV is

above the value defined for

alarm

Setpoint

.

SPA1

PV

dif

Alarm of Differential Value. In this function the

parameters

SPA1

and

SPA2

represent the deviation

of PV in relation to the SP of CONTROL.

SP

PV

SP + SPA1

SP – SPA1

SP

PV

SV – SPA1

SV + SPA1

Positive SPA1

Negative SPA1

difl

Alarm of Minimum Differential Value. It triggers when

the value of PV is below the defined point by (using

the Alarm 1 as example).

SP

PV

SP – SPA1

SP

PV

SP – SPA1

Positive SPA1

Negative SPA1

difk

Alarm of Valor Maximum Differential Value. Triggers

when the value of PV is above the defined point by

(using Alarm 1 as example):

SP

PV

SP + SPA1

SP

PV

SP + SPA1

Positive SPA1

Negative SPA1

ierr

Alarms of the Sensor Break (Sensor

Break Alarm

). It

is activated when the Input presents problems such

as interrupted sensor, bad connection, etc.

Table 02 – Alarm functions

Note: Alarm functions on Table 02 are also valid for Alarm 2 (SPA2).

INITIAL BLOCKING OF ALARM

The initial blocking option inhibits the alarm from being recognized

if an alarm condition is present when the controller is first energized

(or after a transition from run YES

NO). The alarm will be enabled

only after the occurrence of a non-alarm condition followed by a new

occurrence for the alarm.

The initial blocking is useful, for instance, when one of the alarms is

configured as a minimum value alarm, causing the activation of the

alarm soon upon the process start-up, an occurrence that may be

undesirable.

The initial blocking is disabled for the sensor break alarm function

ierr

.

SAFE OUTPUT VALUE WITH SENSOR FAILURE

This function defines an output value (user defined) to be assigned to

the control output in the event of a sensor failure.

When the input sensor is identified as broken, the controller switches

the control mode to MANUAL while forcing MV to assume the user

configured value in the

1E.ov

parameter. This function requires that

one of the alarms be configured as

1Err

and the

1E.ov

parameter

(control output percentage) programmed with a value other then 0

(zero).

Once this function is triggered, the controller remains in SAFE mode

(MANUAL control output) even after the sensor failure appears to be

fixed. The operator intervention is required for switching back to

AUTO mode.

1E.ov

values are only 0 and 100 % when in ON/OFF control mode.

For PID control mode any value in the range from 0 to 100 % is

accepted.

LBD FUNCTION – LOOP BREAK DETECTION

The parameter defines a time interval, in minutes, within which the

PV is expect to react to a control output signal. If the PV does not

react properly within the time interval configured in

lbd.t

, the

controller interprets this as a control loop break and signals this

occurrence in the display.

A LBD event may be sent to any output channel. Simply configure

the LDB function to the desired output channel (OUT1 or OUT2): the

selected output will be activated when a LDB condition is detected.

When the

Lbd.t

parameter is programmed with 0 (zero), the LDB

function is disabled.

The LBD is useful in detecting system failures, such us defective

sensors or actuators, loads and power supply, among others.

OFFSET

Allows fine adjustments to the PV reading for compensation of

sensor error.

USB INTERFACE

The USB interface is used for CONFIGURING or MONITORING the

controller. The

NConfig

software must be used for the configuration.

It makes it possible to create, view, save and open configurations

from the equipment or files in your computer. The tool for saving and

opening configurations in files makes it possible to transfer

configurations between pieces of equipment and to make backup

copies. For specific models, the

NConfig

software also makes it

possible to update the firmware (internal software) of the controller

through the USB.

For MONITORING purposes you can use any supervisory software

(SCADA) or laboratory software that supports the MODBUS RTU

communication on a serial communications port. When connected to

the USB of a computer, the controller is recognized as a conventional

serial port (COM x). Use the

NConfig

software or consult the

DEVICE MANAGER in the Windows CONTROL PANEL to identify

the COM port that was assigned to the controller. Consult the

mapping of the MODBUS memory in the controller’s communications

manual and the documentation of your supervisory software to

conduct the MONITORING process.

Follow the procedure below to use the USB communication of the

equipment:

1.

Download the

NConfig

software from our website and install it on

your computer. The USB drivers necessary for operating the

communication will be installed together with the software.

2.

Connect the USB cable between the equipment and the

computer. The controller does not have to be connected to a

power supply. The USB will provide enough power to operate the

communication (other equipment functions cannot operate).

3.

Open the

NConfig

software, configure the communication and

start recognition of the device.

The USB interface IS NOT SEPARATE from the

signal input (PV) or the controller’s digital inputs and

outputs. It is intended for temporary use during

CONFIGURATION and MONITORING periods. For

the safety of people and equipment, it must only be

used when the piece of equipment is completely

disconnected from the input/output signals. Using the

USB in any other type of connection is possible but

requires a careful analysis by the person responsible

for installing it. When MONITORING for long periods

of time and with connected inputs and outputs, we

recommend using the RS485 interface.