*If motor has no ground tab

(as shown here), solder the

capacitors to motor can.

The XBR Sport has the industry-standard receiver input connector on a user-

replaceable input harness &

works with all major radio brand’s new receivers

.

However, some very old receivers must have the wiring sequence in the plastic

3-pin connector housing changed.

This is important, because receiver & servo

electronics may be damaged if the sequence is incorrect.

JR • Hitec • Futaba • New KO • Airtronics Z

JR, Hitec, Futaba, new KO, & Airtronics Z receivers do not need input

harness re-wiring.

Airtronics Z receivers have blue plastic cases & new KO

cases have tabs on the input harness openings as in

Figure 1

.

• Plug one end of the input signal harness into the

THROTTLE CHANNEL (#2)

of

receiver with the

BLACK wire toward the outside edge

of receiver case.

• Plug the other end of the input harness into 3-pin header inside the ESC’s case

with the

WHITE wire toward the ‘S’ (signal) marking

on the ESC’s case above

the rectangular signal harness opening.

Old-style KO • Old-style Sanwa/Airtronics

If you have an older KO or Sanwa/Airtronics, you must change the sequence

of the ESC’s input harness wires--

Old Sanwa/Airtronics cases are black color &

Old KO cases do not have tab openings, as in

Figure 2

above.

• Using a small flat blade screwdriver,

remove the red & black wires

from the plastic

housing at the receiver end of the input harness as in

Figure 3

below.

•

Interchange the red and black wires

in the plastic 3-pin connector housing at

the receiver end of the input harness.

• Insert modified end of the harness into the

THROTTLE CHANNEL (#2)

of receiver

with the

RED wire toward the outside edge

of receiver case.

• Plug the other end of the input harness into the ESC with the

WHITE wire toward

the ‘S’ (signal) marking

on the ESC’s case.

FIGURE 3

With a small standard screwdriver, gently lift plastic prong

until wire and metal socket easily slide out of plastic housing.

changing wiring sequence

@

receiver end

FIGURE 1

FIGURE 2

New KO

(with tabs)

Old KO

(no tabs)

tabs

no tabs

black

red

red

white

black

white

P3

step

1

–

connect input harness

step

2

–

wirinG speed control, motor, & battEry

1. MOTOR CAPACITORS NOT NEEDED

Novak brushless motors do not require external motor capacitors.

2.

DO NOT USE SCHOTTKY DIODES IN BRUSHLESS-MODE

Schottky diodes must NOT be used with reversible ESCs (including brushless).

Schottky diode usage will damage the ESC & void warranty.

3. FACTORY-INSTALLED POWER CAPACITOR REQUIRED

The factory-installed Power Capacitor MUST be used with brushless &

brush-type motors.

If Power Capacitor becomes dented or damaged, ESC failure can

occur

--replace immediately

.

Longer Power Capacitor wires will decrease performance

.

4. CHECK FOR PROPER GEARING

Refer to the

‘PROPER GEAR SELECTION’

portion of the

PROGRAMMING/

GEARING

Sheet (Pg.5) to determine proper gearing & avoid overheating.

5. SOLDER MOTOR POWER WIRES TO MOTOR

*

Skip this step if installing complete system with ESC factory-wired to motor.

a.

Cut the

BLUE, YELLOW, & ORANGE

silicone motor power wires to the

desired length, and strip 1/8-3/16” of insulation from the end of each

wire. Tightly twist the exposed strands of wire, and tin the exposed end

section of each wire with solder with a good, high heat iron.

b.

Solder the ESC’s

BLUE Phase ‘A’

motor wire to the

motor’s phase ‘A’ solder

tab

. Apply heat to exposed wire with soldering iron, and add solder to

the tip of the iron & the wire--Add just enough solder to form a clean &

continuous joint from the solder tab up onto the wire.

IMPORTANT NOTE:

DO NOT OVERHEAT SOLDER TABS

Prolonged/excessive heating of solder tabs (motor or ESC) will cause damage.

c.

Solder the ESC’s

YELLOW Phase ‘B’

motor wire to the

motor’s phase ‘B’

solder tab

as described in Step 5B above.

d.

Solder the ESC’s

ORANGE Phase ‘C’

motor wire to the

motor’s phase ‘C’

solder tab

as described in Step 5B above.

Note: Make sure no wire strands have strayed to an adjacent solder tab, this will

result in short-circuiting & severe ESC damage, which will void the warranty.

6. CONNECT MOTOR’S SENSOR HARNESS TO ESC

Insert the 6-pin connector on the end of the motor’s Teflon sensor wires

into ESC’s sensor harness socket--the connector is keyed and will only go

together in one direction.

Spiral wrap can be used to protect sensor wires.

7. CONNECT SPEED CONTROL TO BATTERY PACK

Connect the speed control’s Tamiya-style JST battery connector to a charged

4 to 7 cell

(1.2VDC/cell)

or 2-cell LiPo battery pack.

step

3

–

ESC MOUNTiNG

Mount ESC with power wires away from other electronics & moving parts.

Select a location that allows airflow through heat sinks--

If the ESC gets air

flow, it will run cooler; and that means it will be more efficient, and you will go faster!

1. MOUNT SPEED CONTROL IN VEHICLE

Use the included double-sided tape to mount ESC in vehicle

(do not glue)

.

Avoid contact with side walls or other components to minimize vibration

.

Be sure receiver & antenna are mounted as far from ESC, power wires, battery,

& servo as possible--these components all emit RF noise when throttle is

applied. On graphite or aluminum chassis vehicles, it may help to place

receiver on edge with crystal & antenna as far above chassis as possible.

Note: Mount antenna as close to receiver as possible--trail any excess wire off top

of antenna mast (cutting or coiling excess antenna wire will reduce radio range).

2. SECURE POWER CAPACITOR TO CHASSIS

Use included double-sided tape, or a tie-wrap, to mount Power Capacitor

to the vehicle’s chassis or shock tower.

Capacitor can also be tie-wrapped

along the power wires--this requires less space on the chassis

.

3. INSTALL ON/OFF SWITCH

Use a screw or the included double-sided tape, and mount the switch

where it will be easy to access--be sure to select a position where it will

not get damaged or get switched OFF during a crash or roll-over.

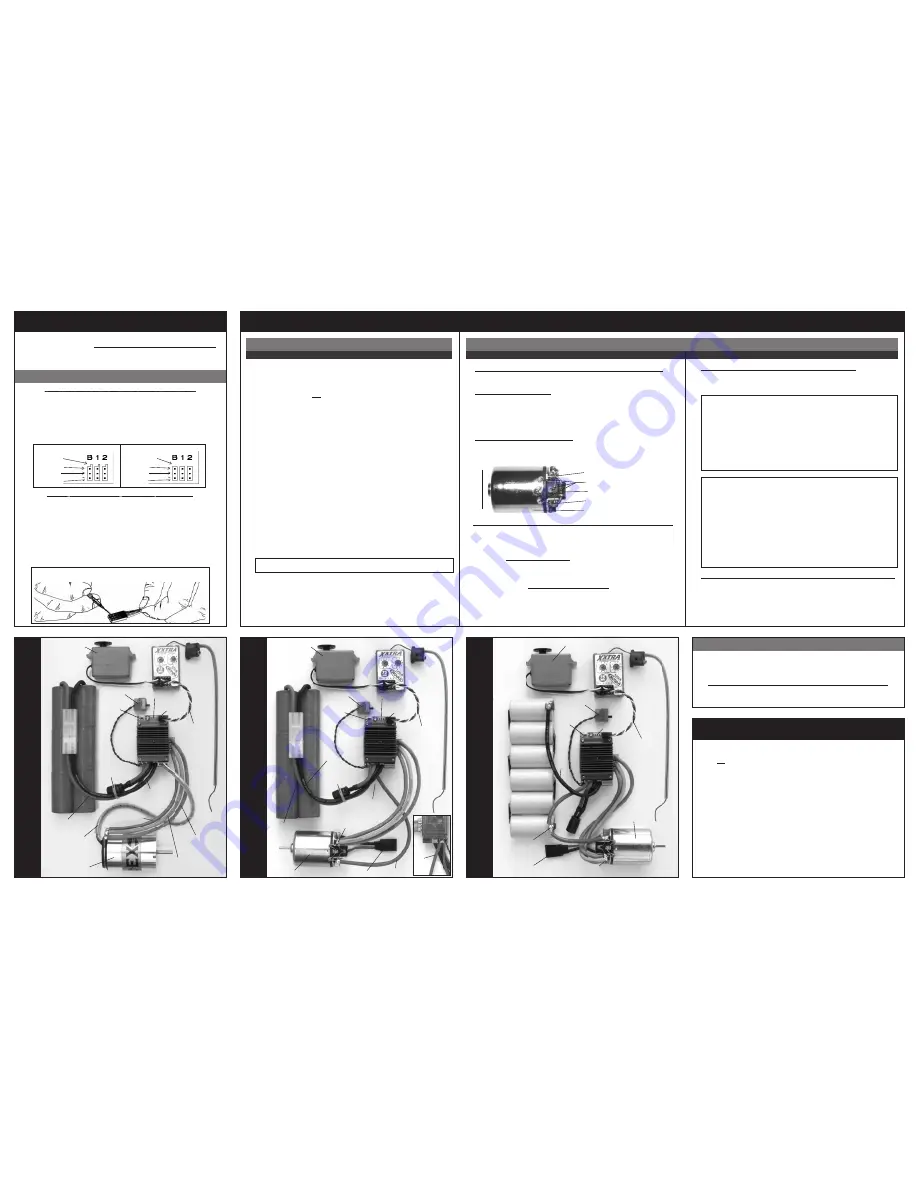

NOvak bRuSHlESS mOtOrS

(Fig.4)

Amber LED flashes 4 times at start-up when transmitter signal is present

bRuSH-typE mOtOrS

(Fig.5-8)

Red LED flashes 4 times at start-up when transmitter signal is present & ESC is is Brush-Mode

1. DISCONNECT BRUSHLESS MOTOR SENSOR HARNESS

The XBR automatically switches to Brush-Mode when the ESC power is switched

ON and no brushless sensor harness is connected.

2. MOTOR CAPACITORS

Electric brush-type motors generate RF noise that causes interference. The

included 0.1µF (50V) non-polarized, ceramic capacitors must be used on all

motors to reduce motor noise & prevent ESC damage.

Note: Some motors come with built-in capacitors. If your motor only has 2 capacitors,

you need to install a capacitor between the positive & negative motor tabs––If you

experience radio interference with built-in capacitors only, install external ones.

Solder 0.1µF (50V) capacitors between:

• POSITIVE (+) & NEGATIVE (–) motor tabs.

• POSITIVE (+) motor tab & GROUND tab*.

• NEGATIVE (–) motor tab & GROUND tab*.

Negative (–) motor tab

0.1µF Capacitors

Schottky diode

Positive (+) motor tab

Ground / motor can

3. INSTALLING OPTIONAL SCHOTTKY DIODE

(Brush-Mode Only)

The XBR Sport does not require an external Schottky diode under most brush

motor conditions.

Note that an external Schottky will optimize the ESC’s braking

and motor performance in applications with heavy or repeated braking

(lap after

lap)

, or when using lower turn modified motors.

• If using an axial lead Schottky diode as shown in the photo above

(older Novak

style--35V/8A min.)

, solder lead

CLOSEST to the silver stripe

on the Schottky

diode’s body to the

POSITIVE (+) Motor Tab

. Solder the lead

OPPOSITE the

silver stripe

on the body to the

NEGATIVE (–) Motor Tab

.

• If using the Novak Racing Schottky Motor Module

(this is the best performing

Schottky diode available)

, solder the

RED wire

from the module to the

POSITIVE

(+) Motor Tab

. Solder the

BLACK wire

from the Schottky module to the

NEGATIVE (–) Motor Tab

.

If Schottky diode is installed backwards it will be destroyed. Replace only with

Schottky diodes with a minimum rating of 35 volts/8 amps.

FIGURE 5

4. SPEED CONTROL’S RED WIRE CONNECTION

To use the XBR Sport with brush-type motors, the

RED

power wire going to

Battery POSITIVE (+)

, must also go to the

POSITIVE (+) Motor Tab

. There

are two ways of doing this, as decribed below:

This method allows you to continue using stick pack batteries with the factory-

installed connector, but can also be used with hard-wired installations. (Figure 6)

a.

Strip about 1/4” of insulation from the end of the included extra piece

of

RED

silicone power. Tin the exposed section of wire with solder.

b.

Solder this wire to the bottom of the ESC’s

Battery POSITIVE (+)

solder

tab

, as shown in Figure 7 inset photo.

Be sure no strands of wire or

solder short-circuit over the gap to the battery negative solder tab.

c.

Determine the proper length for this new

RED

power wire to reach the

POSITIVE (+) Motor Tab

and cut it to this length. Strip & tin the end

of the wire and solder it to the POSITIVE (+) Motor Tab.

This method requires a hard-wired installation & has lower voltage losses. (Figure 7)

a.

Strip 1/4-3/8” piece of insulation from the mid-section of the ESC’s

RED

silicone power wire where you will solder it to either

Battery Pack

POSITIVE (+)

or the

POSITIVE (+) Motor Tab

(whatever component is

in the middle)

. Tin the exposed section of wire with solder.

b.

Solder the exposed section of the ESC’s power wire to

Battery Pack

POSITIVE (+)

or the

POSITIVE (+) Motor Tab

(component in middle)

.

c.

Strip & tin the end of the ESC’s

RED

power wire

(after the first

connection)

, and solder it to the final component--either

Battery Pack

Positive (+)

or the

Positive (+) Motor Tab

.

D.

Strip & tin the end of the ESC’s

BLACK

power wire, and solder it to

Battery Pack Negative (–)

.

5. PREP & SOLDER ESC’S BLUE, YELLOW, & ORANGE WIRES

With brush-type motors, the XBR Sport’s

BLUE, YELLOW, & ORANGE

motor

phase power wires must all go to the

NEGATIVE (–) Motor Tab

.

a.

Strip 1/4” of insulation from the end of the

BLUE, YELLOW, & ORANGE

motor phase wires. Twist & tin the end of each of the wires.

b.

Solder all of the motor phase wires (

BLUE, YELLOW, & ORANGE)

to the

NEGATIVE (–) Motor Tab

.

If you are going to use connectors, we suggest low-loss connectors

(do not use crimp type)

like

Dean’s Ultra. To prevent cross-connection of motor phase wires, we do not recommend

using connectors on the motor power wires of sensor-based brushless motors.

• Use polarized connectors. Reverse voltage will damage the ESC & void warranty.

• Use a female connector on battery packs to avoid shorting.

When wiring the vehicle’s electronics, short wires & clean/neat installations will give

you better performance, higher efficiency, & less radio problems (glitching, etc.). Try

your best to keep power wires away from signal wires & receiver/antenna.

BRUSH-MODE SET

-UP PHOTO 1

‘Y’ Method (FIGURE 6)

BRUSHLESS-MODE SET

-UP PHOTO

(FIGURE 4)

BRUSH-MODE SET

-UP PHOTO 2

Single W

ire Method (FIGURE 7)

Blue, Yellow, and Orange motor phase

wires connect to motor negative

ON/OFF

Switch

User-replaceable

input signal

harness (Ch.2)

Black power wire

(batter

y negative)

Trail excess wire off top of antenna mast

Red power wire

(battery positive)

Blue power wire

(motor phase ‘A’)

(–)

(+)

4 to 6 cell batter

y pack or 2-cell LiPo

Yellow power wire

(motor phase ‘B’)

Orange power wire

(motor phase ‘C’)

Sensor Harness

bundled with

spiral wrap

Servo plugged into

steering ch. (#1)

Novak sensor-based

brushless motor

down to 8.5 turns

P2

‘Y’ connection of

Red power wire

(battery & motor)

brush-type motor

One-Touch

button

Power Cap

tie-wrapped

to wires

Racing Schottky Module

Blue, Yellow, and Orange motor phase

wires connect to motor negative

(–)

(+)

brush-type

motor

(–)

(+)

Racing Schottky

Module

In-Line connection

of Red power wire

(battery & motor

positive)

‘y’

wiring method

single wire method

CONNECTORS & wiring hintS

Status LEDs

Fan power

output pins

(–)

(+)

ON/OFF

Switch

User-replaceable

input signal

harness (Ch.2)

Black power wire (batter

y negative)

Red power

wire (battery

positive)

(–)

(+)

4 to 6 cell batter

y pack or 2-cell LiPo

Servo plugged into

steering ch. (#1)

One-Touch

button

Power Cap

tie-wrapped

to wires

Status LEDs

Fan power

output pins

ON/OFF

Switch

User-replaceable

input signal

harness (Ch.2)

Black power wire (batter

y negative)

Trail excess wire off top of antenna mast

4 to 6 cell batter

y pack or 2-cell LiPo

Servo plugged into

steering ch. (#1)

One-Touch

button

Status LEDs

Extra Red wire soldered to tab

Extra Red wire

soldered to motor