ENGLISH

NovaJet PRO 600e

Quick Start 19

➪

➪

➪

➪

➪

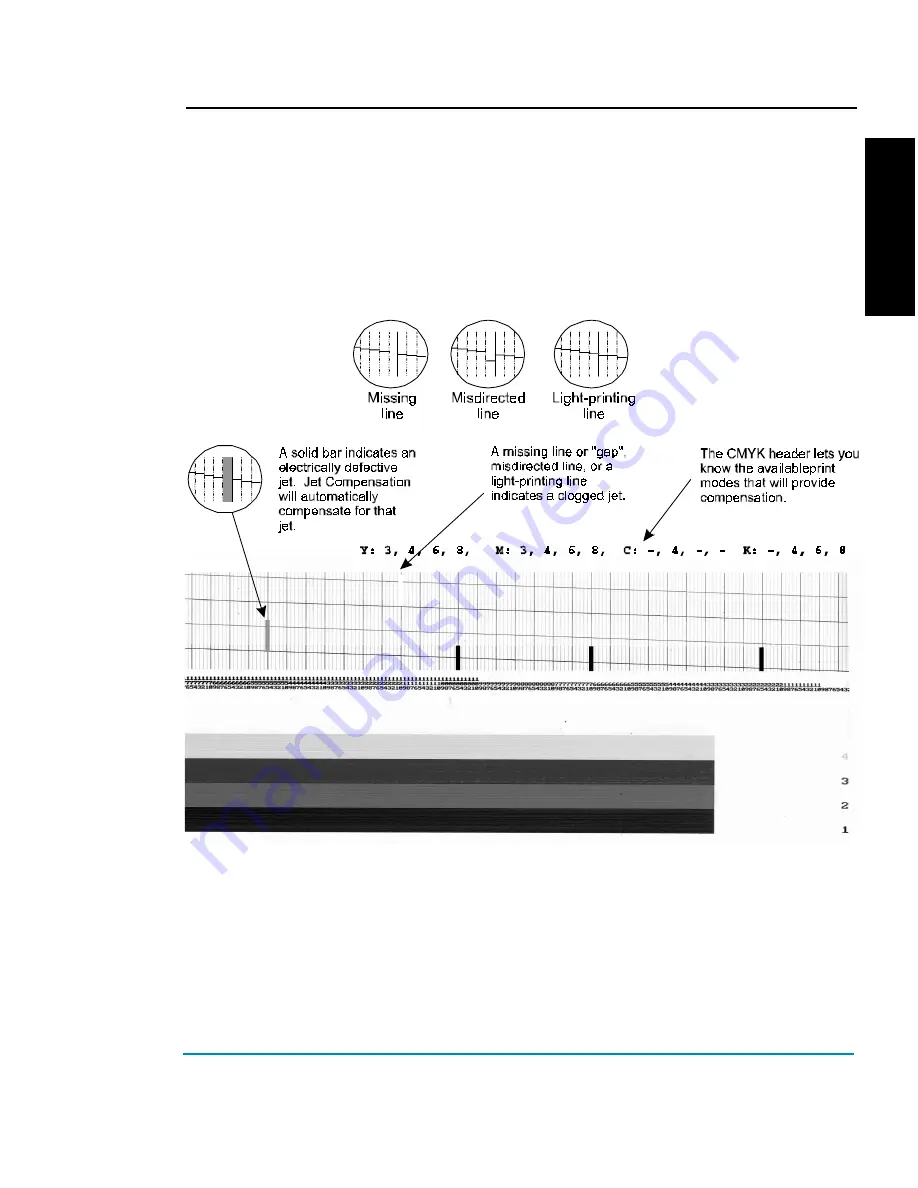

To interpret the Prime test pattern

The test pattern consists of bands of color for each cartridge and a sloping

line. Within the Prime test pattern, each jet is represented with a short

horizontal line. Together, these short horizontal lines form a “stair step”

pattern. Electrically defective jets appear as solid bars. Clogged jets appear

as missing or misdirected lines in the “stair step” pattern. The print modes

for which compensation is available are shown clearly above the Prime.

Clogged jets

Clogged jets cannot be automatically detected and therefore must be cleared manually. If

a jet is clogged, it will appear in the prime pattern as a gap in the sloping line for each

cartridge.

To clear a clogged jet, clean and prime the affected cartridge according to the instruc-

tions in Chapter 4 of the User Guide. Your goal is to eliminate all gaps in the “stair step”

pattern before starting your job.