80-9369-0120-020 (09-08)

7

PAS

DN

T2

T1

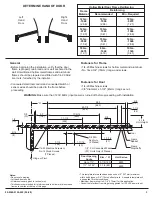

Pinion

Timing Pulley

Screw

ELS Board

Pulley

LED

Timing Belt

Pinion

Timing Pulley

CW

CCW

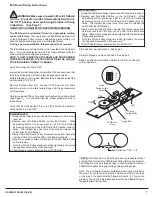

ELS Board Timing Instructions:

**NOTE: If LED should turn off during the above procedure without

any significant movement of ELS Board Pulley, this is not a problem.

The timing zone range is large enough to allow for slight movement

of ELS Board pulley during tightening of pinion timing screw.

Note: The ELS board is factory-calibrated without any pre-load on

the pinion. When the unit is properly installed, and there is pre-load

on the pinion, the light on the ELS board will not be lit. This is not a

problem. The LED is simply intended to set the ELS Board Pulley in

the appropriate “timing zone”.

Pre-Load Arm per instructions. See page 4.

Re-teach Closed and Open Positions. See page 5.

Place 3 position Selector Mode Switch in the “ON” position for

normal operation.

Belt Deflection 1/16” – 1/8”

RH-PUSH UNITS:

Rotate the ELS Board Pulley Counter-Clockwise unit hard stop is

reached.

Slowly rotate ELS Board Pulley Clockwise (away from hard stop

less than 1/8th turn) until the LED on the ELS board lights.

: Pinion pulley should be rotating with the ELS Board Pulley

during this step.

Hold the Pinion Pulley stationary while tightening the pinion

timing pulley screw with a 5/32 hex wrench.**

The ELS board is now calibrated for a RH-PUSH Unit.

Note

•

• Depress and hold Black Button on the ELS Board.

While

depressing button, turn power input to unit “ON” and continue

depressing button until the ELS Board LED flashes three (3)

times. The installer then has three (3) seconds to release the

button after the LED flashes.

•

•

•

!

WARNING: Make sure dip switch #3 on ELS Board

is in the

position and the Selector Mode Switch in is

the “OFF” position when preforming ELS Board Timing

Calibration.

( See Page 2)

“A”

READ STEPS COMPLETELY BEFORE PROCEEDING.

The ELS board is calibrated (Timed) to appropriate starting

zone at the factory.

During a normal installation, this procedure is not required.

If for any reason the ELS Board was removed

or the ELS Board Pulley is turned without the pinion turning, it is

likely the ELS board will need to be re-calibrated (timed).

The ELS board may be timed while unit is mounted to the frame and

door.

The unit may also be timed off the frame and door with the

pinion in the at rest position (no pre-load).

Verify Power Input to Unit is “OFF”

Loosen the pinion timing pulley screw with a 5/32 hex wrench so that

the pinion timing pulley is free to rotate independent of pinion.

Maintain tension on timing belt. Belt should be tensioned so that the

belt can deflect 1/16” to 1/8”.

Remove Pre-Load from Arm. Loosen 1/4-20 Screw on Arm Slide

and allow main arm to rotate toward hinge until it is perpendicular

with frame face.

Determine Hand of Door. See hand marking found on unit manifold

(See Page 2). This will determine the proper calibration step to

follow below.

Verify that ELS Dip Switch #3 is in the

Position and Selector

Mode Switch is turned “OFF”.

NOTE:

CLOSED

IF UNIT IS MOUNTED TO FRAME AND DOOR DURING

THESE PROCEDURES, THE DOOR MUST BE IN THE

POSITION DURING“TIMING”OF BOARD.

“ ”

A

LH-PUSH UNITS:

Rotate the ELS Board Pulley Clockwise unit hard stop is reached.

Slowly rotate ELS Board Pulley Counter-Clockwise (away from

hard stop less than 1/8th turn) until the LED on the ELS board

lights.

: Pinion pulley should be rotating with the ELS Board

Pulley during this step.

Hold the Pinion Pulley stationary while tightening the pinion

timing pulley screw with a 5/32 hex wrench.**

The ELS board is now calibrated for a LH-PUSH Unit.

Note

•

• Depress and hold Black Button on the ELS Board.

While

depressing button, turn power input to unit “ON” and continue

depressing button until the ELS Board LED flashes three (3)

times. The installer then has three (3) seconds to release the

button after the LED flashes.

•

•

•