80-9369-0120-020 (09-08)

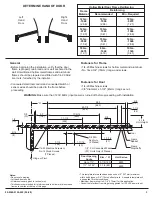

• Determine hand of door from illustration on Page 3.

• Using template, locate and prepare holes in the frame and door:

–

7/8" (22mm) diameter holes

for conduit, for power input and for switch/sensor wires.

On new construction these holes will generally be drilled by

the frame supplier at their shop or at the time the frame is installed in

the wall.

– Prepare

holes for 1/4-20 machine screws or

No. 14 x 2-3/4" (70mm) wood screws. Blind rivet nuts (by others) are

suggested for unreinforced hollow metal frames or for aluminum

frames.

– Prepare

holes for 3/8" diameter sex nuts. Standard units are

supplied with sex nuts and screws for 1-3/4" (44mm) thick door. Sex

nuts and screws for other door thicknesses are available to order.

• Remove cover from door operator assembly and set cover and cover

screws aside.

• Fasten backplate/control assembly to frame face

–

Connect conduit to backplate

fastening backplate to frame.

–

Fasten backplate to frame. Connect

conduit bracket, from screw pack, to the door control's backplate

with two (2) screws provided.Then connect wiring conduit to conduit

bracket on backplate.

• Remove forearm screws from the arm adjusting rod and disassemble

the arm slide and shoe assembly from the arm assembly.

Series 6920 / 6921 Models Only.

IF frame reveal is less than 3-1/4” (83mm) use a saw and cut 1-7/8”

(48mm) off the end fo the adjusting rod.

Frame

Door

Concealed Wired Units Only: Two (2)

NOTE:

seven (7)

two (2)

Concealed Wired Units Only:

Surface Wired Units Only:

NOTE:

before

Installation Sequence

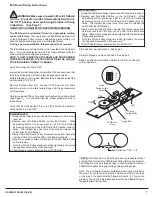

• Fasten arm slide and shoe assembly to the door with the long end of

arm shoe away from the hinge.

• Slide the main arm onto the pinion shaft of the door control unit at a

90° angle to the door control unit and frame. Align arm mark “S” with

the flat corner of the pinion shaft square (see illustration above

right).

•

Install and tighten 1/4-20 Flange Head Screw with 7/16”

wrench or socket.

• Open Door. Align and insert adjusting rod into the arm slide.

Close Door.

• Rotate the main arm away from the hinge until the adjusting rod

and arm slide are perpendicular (at a 90° angle) to the door.

Secure at 90° angle with the forearm screw.

• Adjust valves “S” and “L” using the 1/8” hex wrench provided. See

Hydraulic Adjustment Page 5

Note: A.D.A. Requires that from an open position of 70° the door

will take at least 3 seconds to move to a point 3” (75mm) from the

latched position, measured at the leading edge of the door.

• Make wire connections using Wiring Instructions

No. 80-9369-0901-020

IMPORTANT:

Power Operator Units Only:

Power Operator Units Only:

•

The opening speed of the door

from closed position to 80° must be 3 seconds or longer and 4

seconds or longer to the fully open position.

•

The force required to

a

door from opening or closing must not exceed a 15lbf. (67N)

applied 1" (25mm) from the latch edge of the door at any point in

the opening or closing cycle.

prevent

Left Hand Door Shown

Viewed from ceiling

Looking down on Unit

4

Adjusting

Rod

Arm

Slide

Door

Shoe

Main

Arm

R

L

Y

S

Z

Pinion

Flat

Arm Mark

Frame

Face

Frame

Reveal

Door