20

OM944F 5/21

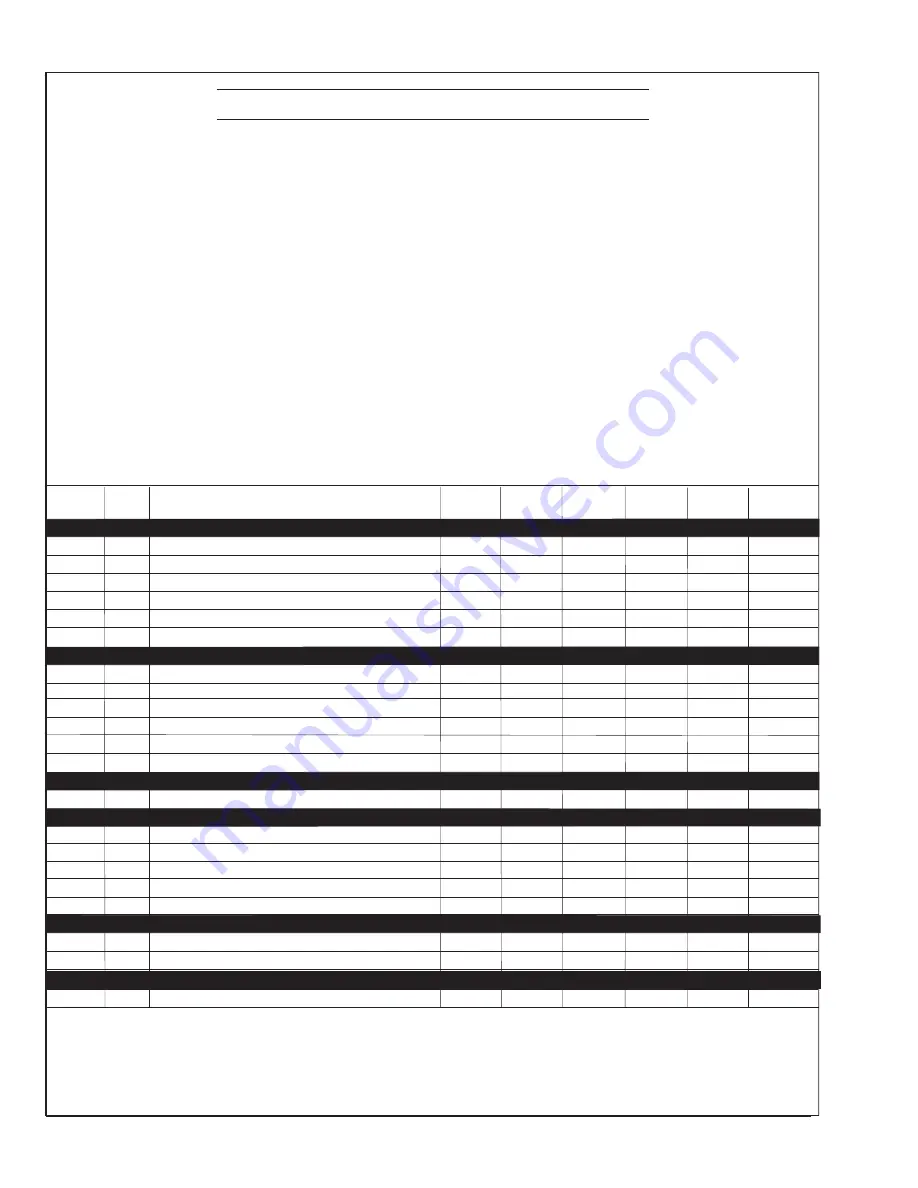

The Servicing Schedule Chart below shows the service schedule required for proper maintenance of your generator set.

More detailed coverage of each Service Point (SP) is listed on the page noted in the ‘page’ column.

DAILY:

Inspect for any signs of fluid leaking

SP1

Check oil level in engine

SP8

Check primary fuel filter

SP14

Check cooling water level

Check sea strainer

AFTER FIRST 50 HOURS:

SP2-3

Change engine oil and filter

SP5

Check V-belt tension

SP19

Check electrolyte level in batteries

EVERY 50 HOURS:

SP5

Check V-belt tension

SP6

Check valve clearances

SP19

Check electrolyte level in batteries

AFTER FIRST 100 HOURS:

SP2-3

Change engine oil and filter

EVERY 250 HOURS:

SP2-3

Change engine oil and filter

SP4

Check air cleaner

SP13

Check turbocharger

SP18

Check zinc electrodes

EVERY 500 HOURS:

SP6

Check valve clearances

SP8

Change primary fuel filter element

SP9

Change secondary fuel filter

SP11

Check injectors

SP14-15

Check cooling system

SP17

Change impeller

SP20

Check battery charge with hydrometer

EVERY 2000 HOURS or as needed:

SP4

Change air cleaner

SP12

Check fuel injection pump

SP16

Check and clean heat exchanger

Servicing Schedule Chart

SERVICE

50

100 250 500 2000

POINT

PAGE

OPERATION

DAILY Hours Hours Hours Hours Hours

ENGINE:

SP1

18

Check oil level

•

SP2

18

Change engine oil

1, 5

•

•

•

SP3

19

Change lube oil filters

1, 5

•

•

•

SP4

19

Check air cleaner

1, 3

•

•

SP5

19

Check V-belt tension

1, 5

•

SP6

20

Check valve clearances

1, 5

•

•

FUEL SYSTEM:

SP7

21

Check primary filter

2

•

SP8

21

Change primary filter element

1, 2, 3

•

SP9

21

Change secondary fuel filter

1, 3

•

SP10

22

Bleed the fuel system

3

SP11

23

Check injectors

1, 6

•

SP12

24

Check fuel injection pump

3

•

TURBOCHARGER:

SP13

25 Check

air, oil, & or leakage

1

•

COOLING SYSTEM:

SP14

26

Check cooling water level

•

SP15

26

Check and flush cooling system

7

•

SP16

27

Check and clean heat exchanger

3

•

SP17

27

Change impeller in raw water pump

1, 3

•

SP18

27

Check zinc electrodes

3

•

ELECTRICAL SYSTEM:

SP19

28

Check electrolyte level in batteries

1, 3

•

SP20

28

Check condition of batteries with hydrometer

1

•

OUT OF SERVICE:

SP21

29

Winterizing or out-of-service

3

1) Perform maintenance once a year even if hour level has not been reached.

2) Consult manufacturer's maintenance schedule, note on chart.

3) Or whenever necessary.

4) Change at 1000 hours.

5) After first 50 hours.

6) Fuel inj. valve opening pressure: 11.77 MPa (120 kgf/cm

2

)

7) Or every 2 years.

8) Valve clearance = .25 mm (0.0098”).

Updated 11-10-20