7

Line Voltage

• An electrical disconnect must be located within sight of and

readily accessible to the unit. This switch shall be capable

of electrically de-energizing the unit. See unit data label for

proper incoming field wiring. Any other wiring methods must

be acceptable to authority having jurisdiction.

• It is recommended that the line voltage to the unit be supplied

from a dedicated branch circuit containing the correct fuse

or circuit breaker for the unit.

• Overcurrent protection must be provided at the branch circuit

distribution panel and sized as shown on the unit rating

label and according to applicable local codes. See the unit

for maximum circuit ampacity and

maximum overcurrent protection limits.

• The installer should become familiar with the wiring diagram/

schematic before making any electrical connections to the

unit. See the unit wiring label or

.

• Use only copper wire for the line voltage power supply to

. Use proper code agency listed

conduit and a conduit connector for connecting the supply

wires to the unit. Even if not required by code, use of rain

tight conduit is always preferred.

• If replacing any of the original wires supplied with the unit,

the replacement wire must be copper wire consisting of the

same gauge and temperature rating.

• Provide power supply for the unit in accordance with the

unit wiring diagram, and the unit rating plate. Use UL listed

conduit and conduit connectors for connecting the supply

wires to the unit and for proper grounding. Field supplied

bushings for the power supply cables must be added to

support and protect the power supply cables.

Grounding

WarnInG:

the unit cabinet must have an uninterrupted or

unbroken electrical ground to minimize personal

injury if an electrical fault should occur. Do not use

gas piping as an electrical ground!

This unit must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the National

Electrical Code (ANSI/NFPA 70) or the CSA C22.1 Electrical

Code. Use the grounding lug provided in the control box for

grounding the unit.

thermostat requirements

• This system can be controlled by any industry standard

thermostat. Set-back thermostats can be used, but are

generally not advantageous with geothermal systems. This

system has such low operational power requirements that

it is counter-productive to use them because the system

must work harder to bring the entire interior air space up to a

preferred temperature, rather than operating on a preferred

temperature “maintain” mode.

• If the system has electric strip heat back-up within the air

handler, the system can operate together with the electric

supplement heat, as the strip heating coils are installed

downstream of the refrigerant heat exchanger. The electric

strip heat is supplemental to the heat provided by the

geothermal system.

• The thermostat used with this equipment must operate in

conjunction with any installed accessories.

ElEctrIcal connEctIons

WarnInG:

ElEctrIcal shocK, FIrE or

EXPlosIon hazarD

Failure to follow safety warnings exactly could result

in serious injury or property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property damage.

• Before servicing, disconnect all electrical power

to the unit.

• When servicing controls, label all wires prior to

disconnecting. reconnect wires correctly.

• Verify proper operation after servicing.

• Electrical connections shall be in compliance with all

applicable local codes and ordinances, and with the current

revision of the National Electric Code (ANSI/NFPA 70).

• For Canadian installations, the electrical connections and

grounding shall comply with the current Canadian Electrical

Code (CSA C22.1 and/or local codes).

Pre-Electrical checklist

• Verify the electrical wiring to the equipment is in compliance

with the maximum electrical capacity listed on the equipment

unit data label. This includes both the compressor unit and

the air handler selected for use, as well as any other related

supplemental equipment.

• Verify the circuit protection (fuse or circuit breaker size) is in

compliance with the minimum circuit amp capacity listed on

the unit data label. This includes both the compressor unit

and the air handler selected for use, as well as any other

related supplemental equipment.

• Verify all electric power wiring connections are correct and

tight prior to turning on any electrical power. Make sure

both the compressor section and air handler have been

properly grounded and have fuses and/or circuit breakers

in the primary electrical service box.

• Verify that the service provided by the utility is sufficient to

handle the additional load imposed by this equipment. See

• Verify factory wiring is in accordance with the unit wiring

diagram

. make sure no connections

came loose during shipping or installation.

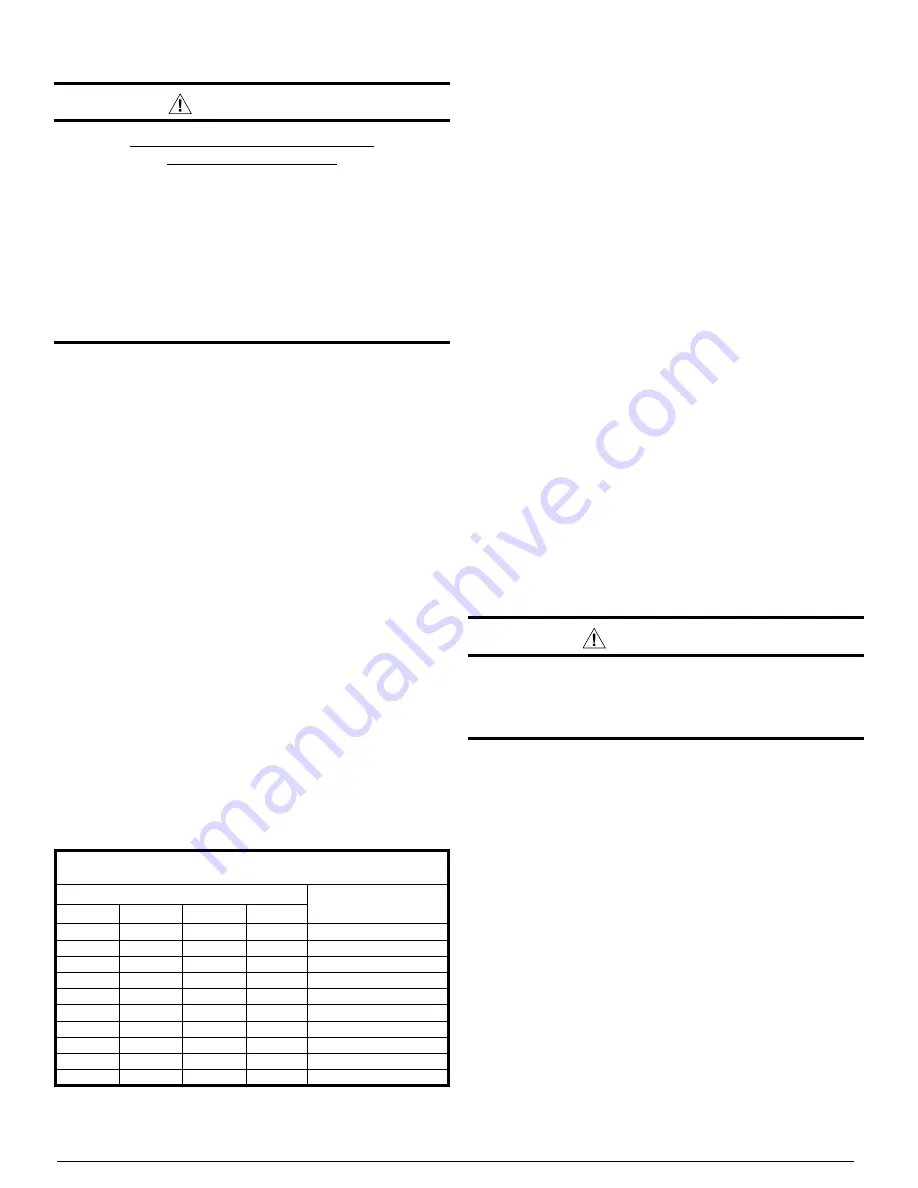

coPPEr WIrE sIzE — aWG

(1% VoLTAGE Drop)

suPPlY WIrE lEnGth-FEEt

suPPlY cIrcuIt

aMPacItY

200

150

100

50

6

8

10

14

15

4

6

8

12

20

4

6

8

10

25

4

4

6

10

30

3

4

6

8

35

3

4

6

8

40

2

3

4

6

45

2

3

4

6

50

2

3

4

6

55

1

2

3

4

60

Wire Size based on N.E.C. for 60° type copper conductors.

table 2. copper Wire size