Reznor, RHC21 8000 Installation EN May 2021 D301319 Issue 0 Page No 13 of 52

4 Installation

4.1 General requirements

It is important that all gas

appliances are installed in

accordance with the rules in force

and by appropriately qualified

persons. Failure to install appliances

correctly could lead to prosecution.

It is in your own interest and that

of safety to ensure compliance with

the law.

Air heaters should not be installed

in corrosive atmospheres i.e. near

plating, spray or de-greasing plants

or in areas where there is a fire risk.

Care should be exercised when designing

ducting systems especially with regard to the

application of restriction and direction turning

fittings, i.e. elbows directly on to the air heater,

doing so can cause an uneven and turbulent air

flow across the heat exchanger resulting in heat

exchanger hot spots and nuisance shut down

of the gas burner due to localized overheating,

thus activating thermal over-heat controls.

The location must also provide sufficient space

to allow the heater to be serviced. Ensure that

the air heater is installed in a level plain and that

the surface onto which it is installed is vibration

free.

4.2 Unpacking and preparation

Prior to dispatch, the air heater was operated

and tested at the factory.

Check the shipping label and data plate to

ensure the specification of gas and electrical

supplies are compatible.

Read this document and become familiar with

the installation requirements and the appliance

before commencing installation.

4.3 Heater location

Do not locate the air heater where it may be

exposed to water spray, rain, etc. The location

chosen for the air heater must permit the

provision of a satisfactory flue system venting to

outdoor atmosphere and adequately ventilated

to provide for combustion air.

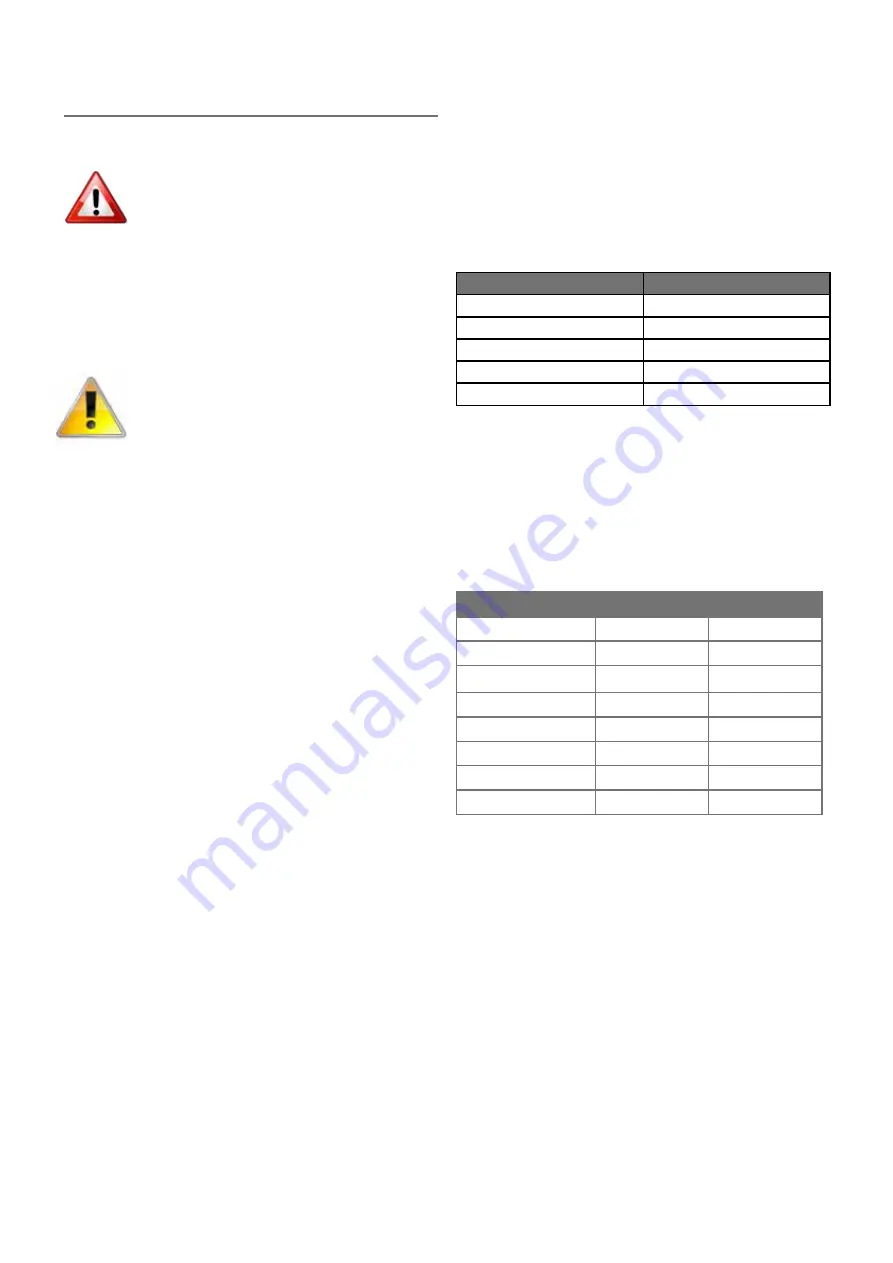

Position

mm

Top

150

Flue connector

150

Access panel

600

Non access side

150

Bottom

50

Table 7 : Installation clearances

4.4 Minimum airflow requirement

The minimum airflow duty through the heating

section (see figure 4 below) must be observed as

indicated in table 8 below.

Model

m

3

/hr

m

3

/s

RHC21 8045-09

6600

1.833

RHC21 8060-12

8750

2.431

RHC21 8075-09

10790

2.997

RHC21 8100-12

14300

3.972

RHC21 8125M15

18000

5.000

RHC21 8150M18

21000

5.833

RHC21 8175M21

21500

5.972

RHC21 8200M24

24000

6.667

Table 8 : Minimum airflow requirements

4.5 Maximum airflow condition

Special attention must be made to ensure that

the temperature rise of the air passing through

the module around the heat exchanger tubes

is high enough to avoid condensation forming

within the tubes.

This condensation forming could occur by

super cooling of the products of combustion.

Such condensation can be the source of severe

corrosion and damage to tubes or part of the

tubes.