13

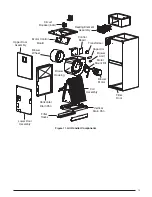

Blower Fan Wheel

- Inspect the blower wheel blades for

accumulations of dirt and clean if necessary. Inspect mounting

nut for tightness when done.

Blower Motor & Assembly

- Inspect the blower assembly

and motor mounting brackets for tightness and corrosion.

Correct deficiencies if necessary. The blower motor contains

sealed bearings and under normal operating conditions,

no maintenance is necessary for the life of the equipment.

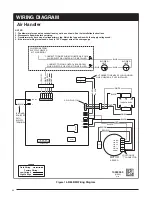

REFRIGERANT CHARGING

WARNING:

NITROGEN

HEALTH

FLAMMABILITY

REACTIVITY

0 Minimal Hazard

1 Slight Hazard

1

0

0

The evaporator coil is shipped from the factory

with a nitrogen charge. Use caution when

preparing coils for field connections. If repairs

make it necessary for evacuation and charging,

it should only be attempted by qualified,

trained personnel thoroughly familiar with this

equipment. Some local codes require licensed

installation service personnel to service this

type of equipment. Under no circumstances

should the equipment owner attempt to install

and/or service this equipment. Failure to comply

with this warning could result in equipment

damage, personal injury, or death.

The system refrigerant charge can be checked and adjusted

through the service ports provided at the front panel of the

outdoor unit. Use only gauge lines which have a Schrader

depression device present to actuate the valve.

Table 3.

Filter Sizes

CABINET SIZE

FILTER SIZE

A

12 x 20 x 1

B

18 x 20 x 1

C

20 x 20 x 1