11

condensing unit or heat pump. Twinning is possible for B64

units with PSC motors. All low voltage wiring instructions,

cautions, and warnings accompanying the air handler remain

applicable, except for:

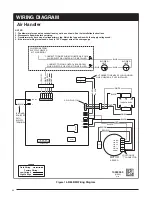

Line & Low Voltage Connections

a. The line voltage connections for both air handlers must

be the same phase and on the same leg of power.

b. Low voltage wiring should be connected as shown in

c. Wire all other low voltage thermostat terminals to

NOTE:

If there is any other air moving device in the

duct work, consult the factory for a resolution.

Heater Kits

When electric heat packages with circuit breakers are field-

installed, the circuit breaker may be used as a disconnecting

means in most applications. Reference the NEC and local

codes for disconnect requirements.

If a heater kit is installed:

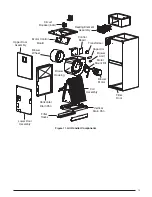

B64BM air handlers are shipped from the factory without

an electric heater kit installed. If electric heat is desired, a

heater kit may be purchased separately and field installed.

Determine the correct size heater kit for your unit by referring

to the heater kit installation instructions.

1. Connect the 2 wire plug of the air handler to the mating 2

wire plug of the heater kit.

2. Connect the line voltage leads to the circuit breaker or

terminal block provided.

3. Connect the heater kit plug with the mating receptacle on

the air handler control board.

If a heater kit is not installed:

1. Remove the 2 wire plug of the air handler by cutting the

wires and discarding the plug.

2. Strip the ends of the 2 air handler wires and connect to

the line-voltage leads with the 2 wire nuts provided.

3. Certain air handler models are equipped with blower limits

. These are left unconnected

if a heater kit is not installed.

Electronic Air Cleaner (EAC)

The unit has an output to power an electronic air cleaner

when the blower is running. This output is rated to 1.0 amp

STARTUP & ADJUSTMENTS

Before You Start the Unit

Prior to start-up, complete the following inspections:

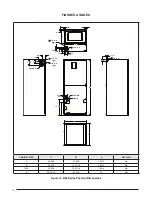

√

Verify the unit is level and properly located with adequate

clearances for servicing the unit as shown in

√

Check condensate drain line(s) for proper drainage.

√

Verify the surrounding area and top of the unit is free from

obstructions and debris.

√

Check all duct connections. Make sure the duct work is

adequately sealed to prevent air leakage.

√

Check all coil connections for leaks.

√

Verify that the line voltage power leads are securely

connected and the unit is properly grounded. Make sure

all doors are installed before restoring power to the unit

√

Verify the thermostat is wired correctly. Make sure all low

voltage wires are securely connected.

√

Verify the power supply branch circuit overcurrent protection

is sized properly.

√

Verify filter is properly and securely installed.

IMPORTANT:

Before starting the unit, install the initial

charge on units that are factory shipped with a nitrogen

holding charge:

1. Read all installation instructions first.

2. Purge the nitrogen holding charge.

3. Evacuate the unit to 350 - 500 microns.

4. Allow the unit to remain under vacuum for at least 30

minutes.

5. Weigh in the proper amount of new (or reclaimed)

refrigerant. Refer to the air conditioner or heat pump

installation manual for the proper type and quantity of

refrigerant.

Air Circulation

Running the Blower Continuously

Set the thermostat’s system mode to

OFF

and the thermostat’s

fan mode to

ON

. The blower motor should run continuously.

Check for air delivery at the register(s). Ensure that there are

no obstructions at the registers or in the ducts.

Turning the Blower Off

Set thermostat’s fan mode to

AUTO

, the blower will shut

down immediately.

System Cooling

1. Set the thermostat’s system mode to

COOL

and fan mode

to

AUTO

. Lower the thermostat’s temperature mode below

room temperature and observe that the blower energizes.

Check the air being discharged at the register is cooler

than room temperature. Verify unit refrigerant pressures

are in order. Blower should be turning in direction indicated

by arrow.

NOTE:

DO NOT alter unit wiring. Listen for any unusual

noises. Locate the source and correct as needed.

2. Allow the unit to run for several minutes and then set the

thermostat’s temperature above room temperature. Verify

the blower cycles off with the thermostat.

System Heating

1. Set the thermostat’s system mode to

HEAT

and the fan

mode to

AUTO

. Increase the thermostat’s temperature

above room temperature and observe that the blower

energizes. Check the air being discharged at the register

is warmer than room temperature.

2. Allow the unit to run for several minutes and then set the

thermostat’s temperature below room temperature. Verify

the blower cycles off with the thermostat.

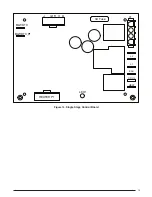

Selecting Minimum Electric Heat Airflow

The minimum electric heat airflow setting controls the

minimum air flow that will be produced whenever electric

heater kits are used. When the electric heater kit is energized

along with a heat pump, the airflow may be higher depending

on the basic cooling/heat-pump airflow setting. The minimum

electric heat airflow is selected by the red blower wire on

3-speed models.

Blower Configurations

Determining Nominal System Capacity

To select the appropriate airflows for the air handler, the

nominal system capacity must be known. The nominal system

capacity is always the nominal capacity of the outdoor unit.

However, in some situations the nominal system capacity

may not be the same as the nominal capacity of the air

handler. Always refer to the nominal capacity of the outdoor

unit to determine the nominal system capacity. Use

as a guide for acceptable airflow CFM

(dependent on air handler cabinet size and nominal capacity

of the outdoor unit).