Maintenance and Servicing |

46

RH2 Maintenance Checklist

Model #: _________________

Serial #: _________________

Tag: ________

Cylinder #:

CHECK CYLINDER

Cylinder spent), yellow LED flashing 4 times in sequence.

(If Yellow LED is On and cylinder is not new then cylinder will have to be replaced soon.)

REPLACE CYLINDER

Cylinder drained.

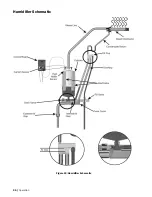

Disconnect open, On/Off/Drain switch off, water shut off valve closed, cover removed.

Cylinder removed

Drain valve removed / cleaned / new O-Ring

Drain valve installed / ground wire attached.

New Cylinder Installed

New cylinder model #

(Should be same as removed cylinder)

Cylinder plug colors match cylinder dots.

Cylinder plugs snug and in good condition.

High Water Sensor plug snug and in good condition.

Cover replaced, water shut off valve open, On/Off /Drain switch On, Disconnect Closed

SYSTEM CHECK

Yellow Led flashing? No

Yes

Flash Sequence?

(See Troubleshooting Chapter for actions if yellow LED is flashing

)

Cylinder plugs snug and in good condition.

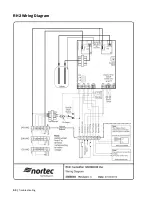

Electrical wiring not loose and in good condition,

Steam hoses and steam lines in good condition / No kinks in hose,

No Signs of water leaking around humidifier, steam line, condensate returns,

Inspected by:

Date of inspection: _______/_______/______

Company: