P.O. Box 40525, Houston, Texas USA 77240-0525

Tel: 713·466·3552 · Fax: 713·896·7386

www.norriseal.com

2700A — ©2015, February, 2015

O

PERATING AND

M

AINTENANCE

M

ANUAL

Series 2700A Control Valve

2.0 Valve Maintenance

Before attempting any repairs, isolate

the control valve from the system and

make sure that all pressure is released

from the valve body, both up and

downstream. Shut off and vent supply

and signal air lines to the actuator.

1. Isolate the valve from the

process.

2. Shut off all control and supply

lines to the actuator.

3. Release the process pressure.

4. Vent the actuator loading

pressure.

Valve parts are subject to normal wear

and must be inspected and replaced

as necessary, with the frequency

of inspection depending upon the

severity of the repair needed. The

following sections describe the

procedures for disassembling and

reassembling the valve for normal

maintenance and troubleshooting.

All maintenance operations may

be performed while the valve body

remains in line, as long as the line is

not in service and/or is isolated from

active process by block valves. Table

2 lists the maintenance schedule for

the valve assembly. Table 5 provides

assistance in troubleshooting valve

operation.

NOTE: An increase in plug seating

force will also require an increase in the

diaphragm supply pressure required to

fully open the valve.

NOTE: Excessive adjustment of the

spring to increase seating force may

shorten the valve stroke preventing the

valve from opening fully.

Direct (fail open):

Loosen

the lock nut on the adjusting

nut below the spring.

Turn the adjusting nut

clockwise to increase the

spring’s preload and turn it

counterclockwise to reduce

the preload. Retighten the

nut after adjustment.

NOTE: In a direct setting, any increase

in pressure may produce an increase

in plug seating force when the valve is

closed. Do not exceed 55 psi supply

pressure.

Stem travels for valves with full size

trim are listed below. For valves with

reduced or restricted trim, stem travel

may be less than the value shown.

Page 2 of 12

pipeline. For threaded (NPT)

bodies, use pipe thread sealant.

The bodies are rated ANSI 150,

300, 600, 900, 1500 or 2500

class. Do not install the valve

in a system where the working

pressures exceed the limitations

noted on the nameplate.

Where piping is insulated

do not

insulate the valve above the

valve bonnet.

Connect the instrument air to the

actuator or positioner connection.

Refer to the nameplate for

maximum instrument air pressure.

Check for proper valve operation

by cycling the actuator several

times and observing the stem

movement.

Do not exceed the maximum instrument

air pressure stamped on the valve

nameplate. Under no circumstances

should the actuator loading pressure

exceed 55 psi.

Actuator springs are pre-set at

a factory and may require ad-

justments to suit your specific

operating conditions. To adjust

the spring setting, complete the

following:

Reverse (fail close)

:

Loos-

en the lock nut on the stem

below the spring, and turn

the adjusting nut above

it clockwise to increase

the spring’s pre-load and

plug seating force. This will

achieve a more secure shut-

off. Turn the adjusting nut

counterclockwise to reduce

preload. Retighten the nut

after adjustment.

WARNING!

WARNING!

5.

6.

7.

8.

a.

b.

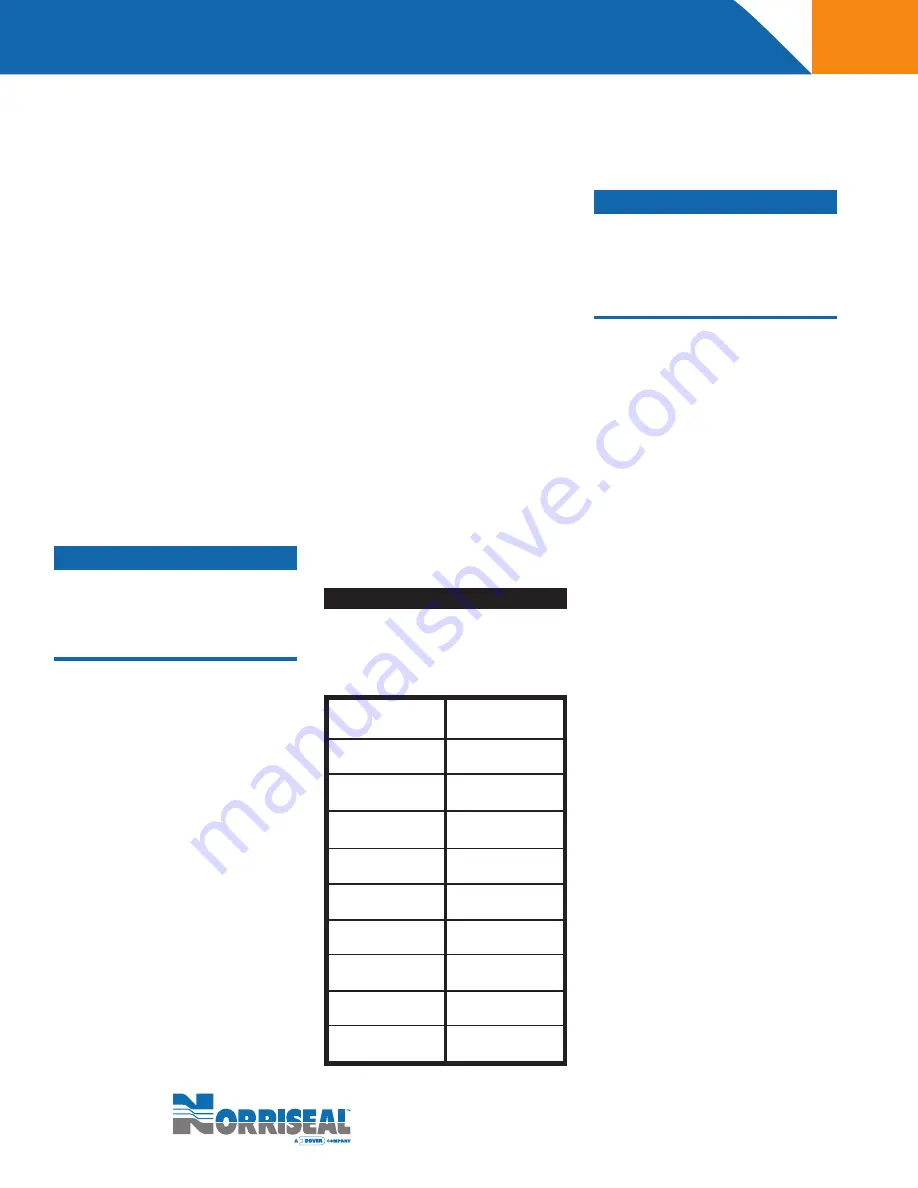

T A B L E 1

BODY SIZE (in)

1.00

1.50

2.00

3.00

4.00

6.00

8.00

10.00

12.00

STEM TRAVEL (in)

0.75

1.00

1.25

1.50

2.00

2.75

4.00

4.00

4.00