24

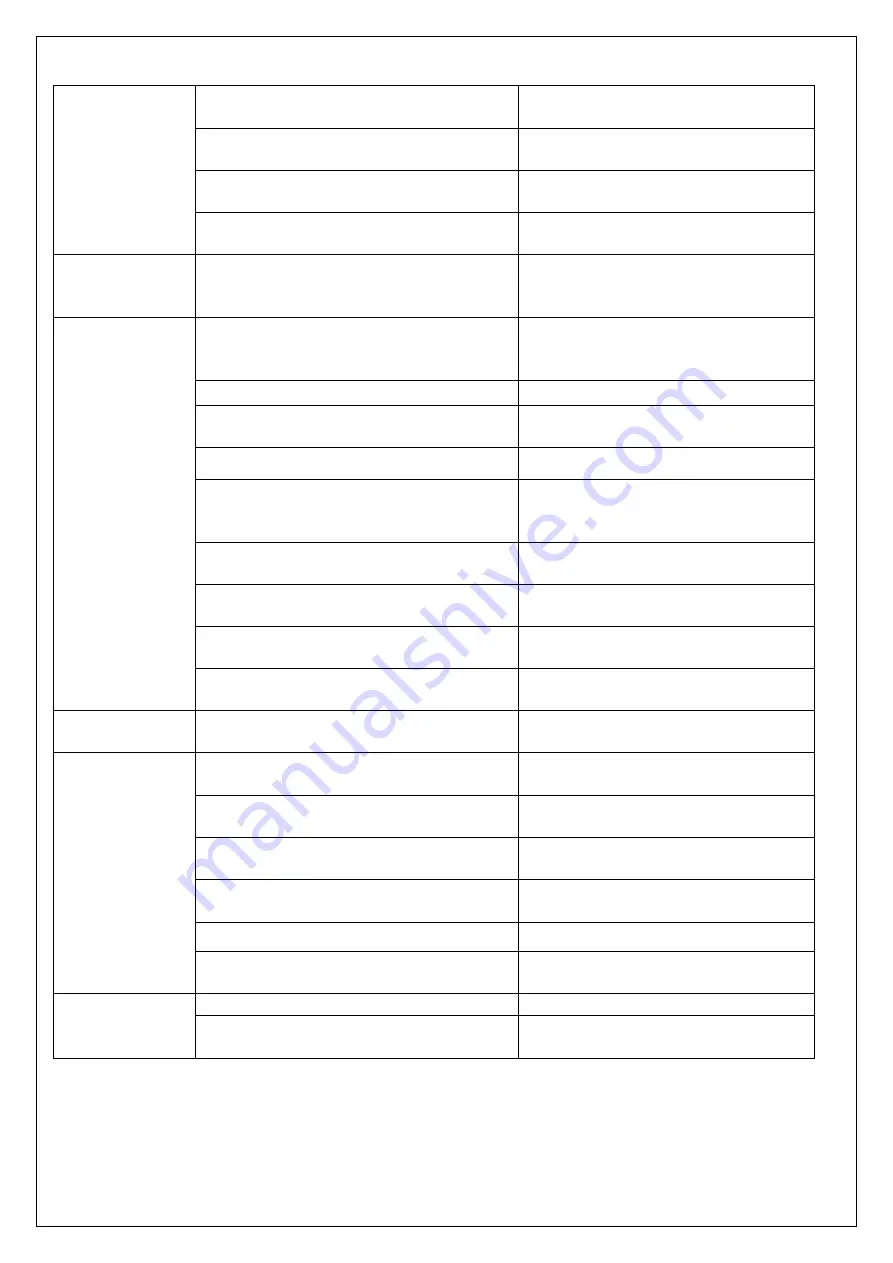

Oil leakage

Repair the hoses and/or the

sealing of the cylinder

Lifting stops at

71”

Move the protective arms into the

downside position

Lifting stops at

71”

Check the sensor for the protective

arm

Height sensor for 71” height defect

Check the height sensor on the

mast

Oil leakage

from air

breathing

Excessive quantity of oil. Reduce

oil

quantity.

Stacker not

starts operating

Battery is charging

Charge the battery completely and

then remove the main power plug

form the electrical socket.

Battery not connected

Connect the battery correctly

The fuse is faulty

Check and eventually replace

fuses

Battery discharged

Charge the battery

Combined emergency switch is

activated

De-activate the combined

emergency switch by insert and

pull the knob.

Tiller in the operating zone

Move the tiller firstly to the braking

zone.

Protective arms in the upright position,

platform folded upright

Move the protective arms into the

downside position

Foldable platform or protective arms in

one of the allowed positions

Check the proximate sensors for

the arms and platform

Foldable platform or protective arms

not in one of the allowed positions

Check the correct function of the

arms and/or platform

Only travelling

in one direction

The accelerator and the connections

are damaged.

Check the accelerator and the

connections.

The stacker

only travels

very slowly

The battery is discharged.

Check the battery status at the

discharge indicator

The electromagnetic brake is

engaged.

Check the electromagnetic brake

The relating tiller cables are

disconnected or damaged

Check the tiller cables and

connections.

Defective height sensor for reduced

speed at

12” height

Check the sensor

Electric system overheated

Stop using and cool down the truck

Defective heat sensor

Check and if necessary replace the

heat sensor

The stacker

starts up

suddenly

The controller is damaged.

Replace the controller.

The accelerator not moves back to its

neutral position.

Repair or replace the accelerator.

If the truck has malfunctions and can’t be operated out of the working zone, jack the truck up and go with

a load handler under the truck and safe the truck securely. Then move the truck out of the aisle.