Use and Maintenance Manual model “A10V - A10C PLUS QUADRA”

11

ENGLISH

ENGLISH

4

MAINTENANCE

The maintenance operations, excluding routine

cleaning (explained in the relevant paragraph), must

be carried out by authorised, technical

staff. Remember, before carrying out any

maintenance operation, implement the following

precautions:

• all parts of the product must be “cold”;

• ensure there is no form whatsoever of

combustion (for example ash still hot);

• use of safety devices as per the directive;

• remove the plug from the electrical socket;

• having terminated maintenance, reset the prod

-

uct paying attention to re-activate all the safety

devices.

4.1 SMOKE SYSTEM MAINTENANCE

The chimney flue must always be cleaned,

since deposits of soot or fuel residue reduce the

section blocking its draught, compromising good

operation of the product and, if in large quantities,

can catch fire. It is compulsory to have a qualified

chimney sweep clean and check the chimney flue

and the stack at least once a year or after pro-

longed stoppage due to non-use of the appliance.

At the end of the control/maintenance, ask for a

report to be issued stating the system is safe.

Lack of cleaning prejudices safety

of the system.

It is compulsory for the system to be grounded and

have a differential switch in compliance with legis-

lation in force. Furthermore, ensure the socket is

compatible with the type of plug on the power

cable used.

4.2 PRODUCT MAINTENANCE

Carry out at least once a year or on each “Service

Hours” signalling (signal that appears on screen

when the working hours have been exceeded, over

which

excellent product operation is not guaranteed). In

this phase, the authorised technician should:

• completely and accurately clean the

smoke pipes;

• check the sealing status of all the gaskets;

• remove broken pellet residue inside

the pellet tank;

• re-assemble all parts of the appliance;

• check correct operation and good quality

combustion

5.1 PRODUCT DATA SHEET

5.2 TECHNICAL FEATURES

* this value can vary based on the type of energy

class of the home and the type of pellet used.

The data outlined are approximate and non-binding

and can vary based on the type of pellet

used. The manufacturer reserves the right

to make changes for the purpose of

improving product performance.

5

TECHNICAL DATA OF THE PRODUCT

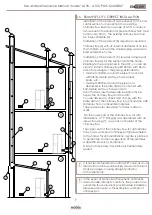

This chapter issues to the end user all the information

relating to the technical data of the product, the

dimensions, the installation measurements, the mini-

mum distance to comply with from walls

and furniture, sofas, etc.

SCHEDA PRODOTTO

EU 2015/1186

Brand

Nobis

Model

A10V - A10C PLUS QUADRA

Energy efficiency class

A+

Direct thermal power (Kw)

10.1

Indirect thermal power (Kw)

9.1

Energy efficiency index

128.3

Useful efficiency (Nominal power %)

90.2

Useful efficiency (Reduced power %)

93.7

Comply with the warnings and instructions for installation

and periodic maintenance of the instructions manual.

Model

A10V - A10C PLUS QUADRA

Reduced

Nominal

Weight of appliance (kg)

163

Ø air inlet (mm)

60

Ø smoke outlet pipe (mm)

80

Vol. max. heating* (m

3

/h)

224

Power introduced (

kW)

3.7

10.1

Yield introduced (

kW)

3.5

9.1

Yield (

%)

93.7

90.2

CO 13% O

2

(

%)

0.013

0.002

Tank capacity (kg)

19

Pellet hourly consumption (

kg/h)

0.77

2.10

Autonomy (

h)

24.5

9.0

Absorbed electrical power (W)

260

Electrical power supply (V-Hz)

230-50

Discharge gas flow (

g/s)

3.63

5.91

Minimum draught (

Pa)

10

12

Smoke temperature (

°C)

85

180