Scrub System, Disc

67

Service Manual – SC2000

Removal and Installation

Brush Motor Amperage Check

Warning! This procedure must be

performed by qualified

personnel only.

1.

Drive the machine on a level floor.

2. Remove the brush.

3. Lift the recovery tank assembly and the driver’s

seat.

4. Disassemble the electronic component

compartment cover and the function electronic

board panel.

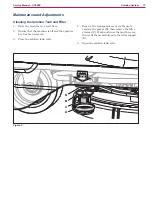

5. Disconnect the drive system connector (A)

(Figure 6) on the function electronic board (B) to

disable machine movement.

6. Insert the operator key in its slot.

7. Press the One-Touch button

to lower the

brush deck.

8. Apply the amp clamp (C) to an electrical cable

(D) of the brush motor.

Note:

Use a jumper wire to disable

the driver’s seat sensor.

9. Activate the brush by pressing the accelerator

pedal, then check that the brush motor

amperage is between 3 and 4A at 20V(*).

10. Deactivate the brush by releasing the

accelerator pedal and raise the brush deck by

pressing the One-Touch button

.

11. Remove the amp clamp (C).

12. If the amperage is higher, perform the following

procedures to detect and correct the abnormal

amperage:

◦

Check the brush motor carbon brushes.

◦

Remove the brush motor then check the con-

dition of its components.

13. If the above-mentioned procedures do not lead to

a correct amperage, it is necessary to replace the

brush motor.

Figure 6

D

B

C

A

(*) Voltage value supplied by the electronic board to the brush gearmotor when the gearmotor amperage is

less than the value of the RPM parameter.