16

NEXCOBOT Co., Ltd.

www.nexcobot.com

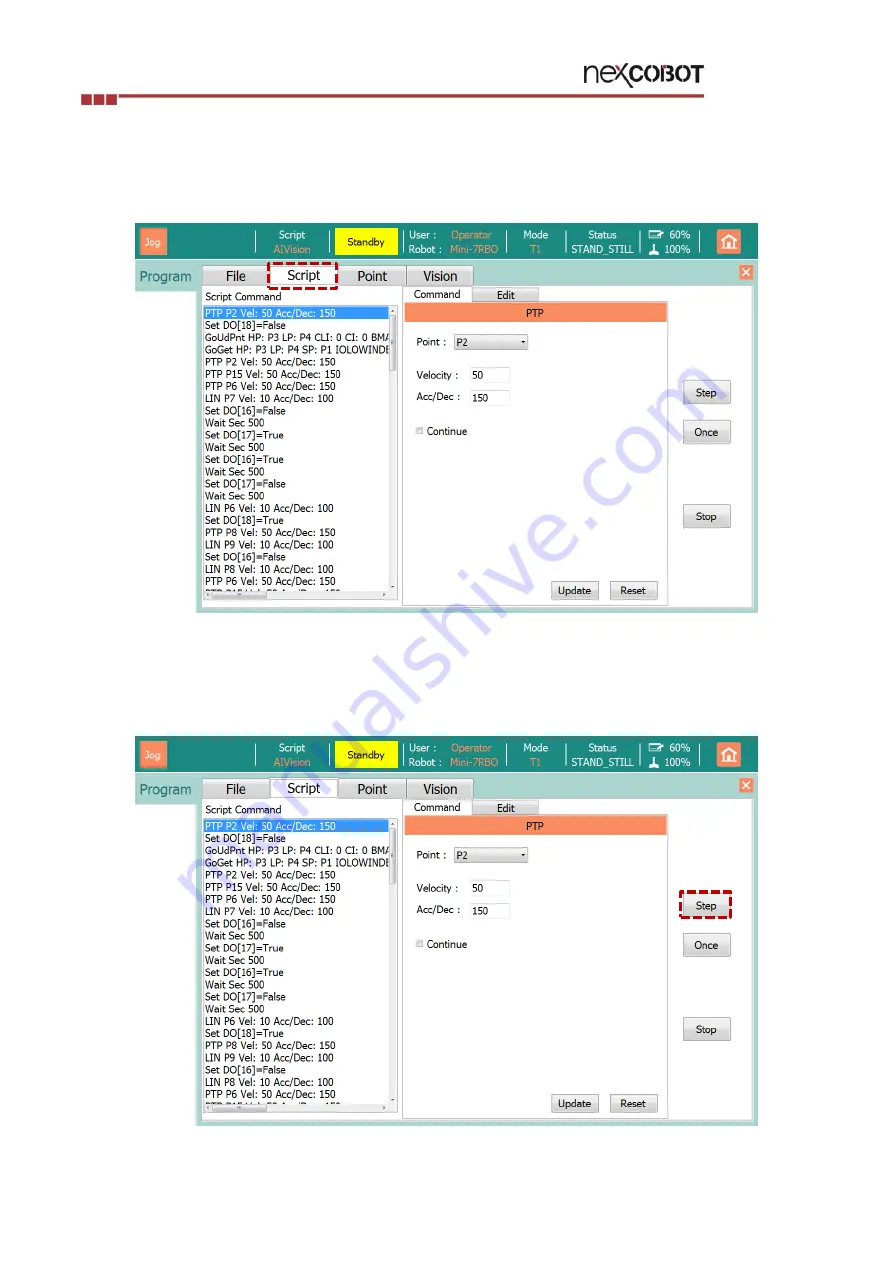

Script Page: User can write a robot script to ask robot to move to desire

target by desire movement. While writing a robot script, user need to use

command page to select desire command for robot script, and user also

need to set the desire parameters for selected command.

For example if user want to control robot to move to P2 point, first step is

selecting

『

PTP P2 Vel:50 ACC/Dec 150

』

from Script Command and

keep pressing

『

Step

』

button, and then robot will move to P2 position.

Summary of Contents for MiniBot

Page 1: ...NEXCOBOT Co Ltd www nexcobot com MiniBot 7 Axis User Manual Version 1 0 Date 2018 10 31 ...

Page 3: ...iii NEXCOBOT Co Ltd www nexcobot com Document Version Version Release 1 0 First released ...

Page 7: ...3 NEXCOBOT Co Ltd www nexcobot com ...

Page 16: ...12 NEXCOBOT Co Ltd www nexcobot com Status User can choose which robot to use ...

Page 28: ...24 NEXCOBOT Co Ltd www nexcobot com Configuration Tool Information ...

Page 32: ...28 NEXCOBOT Co Ltd www nexcobot com Axis 5 Axis 6 Axis 7 ...