-6-

TYPES OF COMBUSTION AIR FOR WOOD HEATING

Unlike older airtight heating appliances, low emission furnaces have more than one location and control for

supplying combustion air into the firebox. These additional air inlets allow for near complete combustion of wood

gases and particulates. It is important to understand how these three different air supplies work.

PRIMARY AIR

Starts the fire and controls the burn rate. Opening or closing this air supply regulates how hot the furnace will

burn. Primary air is supplied by the following: an adjustable slide plate to vary the burn rate and sliding the plate

to the light is a hotter fire. Use the Primary Air Control (PAC) slide plate knob on the right side of draft fan to

control the burn rate. Always start the fire with the PAC set on high and leave it on high until the secondary flames

continue to burn at the rear of the firebox below the baffle, then adjust the PAC to a lower setting (to the left).

Adjust the PAC accordingly when refueling. An established hot coal bed requires less primary air to restart a

fresh load of firewood. The (PAC) also called combustion air is normally set in the center between maximum and

minimum. The thermostat also controls the amount of primary air entering the unit by turning on the draft fan and

adjustment of slide plate (A). Turn up the thermostat for 10 to 20 minutes after reloading for a good start, then turn

down to desired temperature. It is very important to keep the secondary flames burning to maximize heat output

and minimize air pollution, so some experimentation will be necessary because each installation is different.

Wood moisture content will also affect the amount of time that a unit will need to burn on high after each reload.

SECONDARY AIR SLIDE

Is located below the firedoor. Secondary air allows the furnace to burn clean. This preheated air enters the

upper firebox just below the baffle plate. This superheated air mixed with the wood gases and flames ignites,

reaching temperatures in the 1100F to 1600F range. Without secondary air these volatile gases would exit the

furnace unburned as creosote, smoke, particulates, and high levels of Carbon Monoxide, increasing pollution

and greatly decreasing efficiency. Heat comes from burning the wood gases, not the wood, which itself turns

into black charcoal after the gases are all released and then to gray ashes. Secondary air increases a furnaces

efficiency by approximately 40% greatly reducing the amount of wood required for a heating season (up to 1/3

less wood).

CAUTION:

Never attempt to burn your furnace with the secondary air slider closed or your furnace will burn

dirty, produce creosote and be less efficient. The SAC must be left in the open position to burn optimally.

WARNING:

WATCH YOUR CHIMNEY – If you cannot see any visible smoke coming out you are operating

your stove correctly. If you can see smoke, then adjust for additional primary air until the smoke disappears.

Remember, smoke equals lost heat!

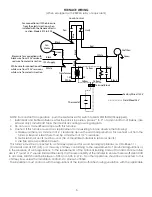

(A) PAC, PRIMARY AIR CONTROL (B) SAC, SECONDARY AIR CONTROL

B

A

Summary of Contents for WFA-85

Page 21: ...21 Notes...