E265C-E305C

SAFETY INFORMATION

S1 - 2

OPERATING

Do not run the engine in closed buildings without

proper ventilation capable to remove harmful exhaust

gases which concentrate in the air.

Keep the operator’s compartment free of foreign

objects, especially if not firmly secured. Never use

the machine to transport objects, unless proper

securing points are provided.

Do not carry riders on the machine. Study and

familiarise with escape routes alternative to normal

exit routes. For your personal safety, do not climb on

or off the machine while it is in motion.

Make sure that bystanders are clear of the machine

operating range before starting the engine and

operating the attachment. Sound the horn.

Obey all hand signals, safety indications and signs.

When backing, always look to where the machine is

to be moved.

Be alert of the position of bystanders. Should

someone enter the work area, stop the machine.

Maintain a safe distance from other machines or

obstacles to ensure required visibility conditions.

Always give way to loaded machines.

Maintain a clear vision of the surroundings of the

travel or work area at all times. Keep cab windows

clean and repaired.

When pulling loads or towing through a cable or

chain, do not start suddenly at full throttle. Take-up

slack carefully. Avoid kinking or twisting chains or

cables.

Carefully inspect the towing items for flaws or

problems before proceeding. Do not pull through a

kinked chain or cable as the high anomalous stresses

existing in this condition may induce failures in the

kinked portion.

Always wear heavy gloves when handling chains or

cables.

Chains and cables should be securely anchored

using suitable hooks. Anchor points should be strong

enough to withstand the expected load.

Keep anyone clear of anchor points and cables or

chains.

Do not pull or tow unless the operator’s

compartments of the machines involved are properly

protected against possible backlash in case of cable

or chain failure or detachment.

Be alert of soft ground conditions close to newly

constructed walls. The fill material and machine

weight may cause the wall to collapse under the

machine.

In darkness, check area of operation carefully before

moving in with the machine. Use all lights provided.

Do not move into low visibility areas.

If the engine tends to slow down and stall for

whatever reason under load or at idle, immediately

report this problem to the maintenance managers for

proper action.

Do not operate the machine until this condition is

corrected. Regularly check all exhaust system

components, as exhaust fumes are toxic for the

operator.

Operators must know the performance of the

machine they are driving. When working on slopes or

near sudden level drops in the terrain, pay attention

not to lose adherence and avoid loose soft ground

since overturn or loss of machine control could result.

If noise level is high and exceeds 90 dB (A) over 8

hours at the operator’s ear, wear approved ear

protection in compliance with local regulations.

Do not operate the machine if you are extremely tired

or feel ill. Be especially careful towards the end of the

working shift.

Where removable counterweights are provided, do

not operate the machine if they have been removed.

When operating the machine, keep in mind height

limits of overhead doors, arches, overhead cables

and lines as well as width limits of corridors, roads

and narrow passages.

Also, get to know load limits of the ground and

paving type of the ramps you are to work on.

Beware of fog, smoke or dust that obscure visibility.

Always inspect the working area to identify potential

risks such as: inclines, overhangs, trees, demolition

rubble, fires, ravines, steep slopes, rough terrain,

ditches, crowns, ridge trenches,diggings in traffic

areas, crowded parking lots, crowded service areas,

fenced zones. In such conditions, proceed with

extreme care.

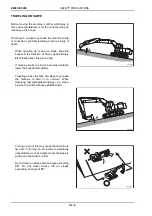

Whenever possible, avoid crossing over obstacles

such as very rough terrain, rocks, logs, steps,

ditches, railroad tracks.

When obstructions must be crossed, do so with

extreme care and at a square angle, if possible. Slow

down.

Ease up to the break-over point, pass the balance

point slowly and ease down the other side also using

the attachment, if necessary.

To overcome deep trenches or sinking ground, place

the machine perpendicular to the obstacle, drastically

reduce ground speed and start crossing using also

the attachment if necessary, only after assessing that

ground conditions allow the traverse safely and

without risks.

The gradient you may attempt to overcome is limited

by factors such as ground conditions, load being

handled, machine type and speed, and visibility.

There is no substitute for good judgement and

experience when working on slopes.

Avoid operating the attachment too close to an

overhang or high wall, either above or below the

machine. Beware of caving edges, falling objects

and landslides. Remember that such hazards are