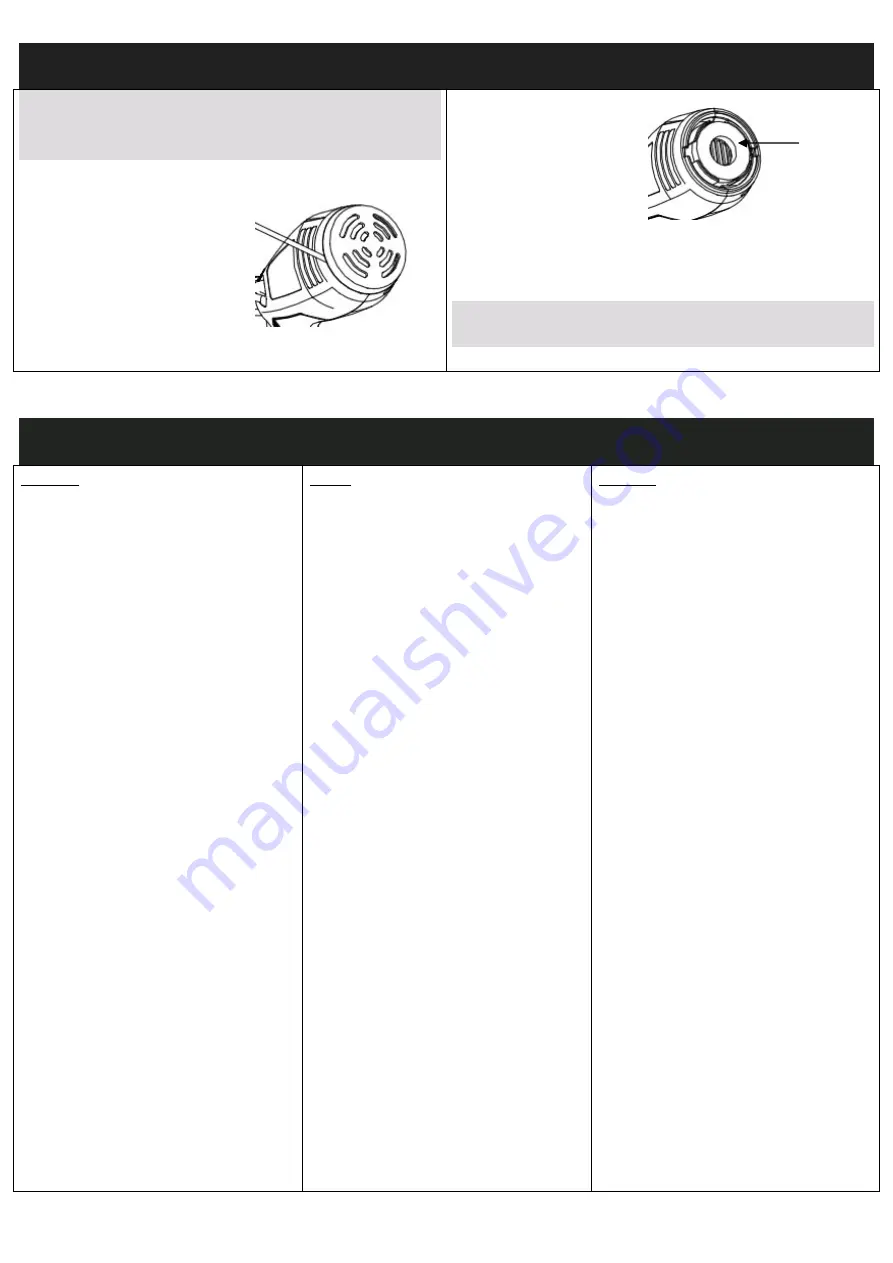

Maintenance

You

should

inspect

the

air

filter

in

the

Air

Compressor

Assembly

to

see

if

it

is

excessively

dirty.

If

it

is

dirty,

follow

the

steps

below

to

replace

it.

1.

Unplug

the

spray

gun.

Remove

the

filter

cover

with

a

tool

(such

as

a

flat

screw

driver)

2.

Remove

the

dirty

filters

and

replace

with

new

ones.

3.

Secure

the

cover

back

onto

the

turbine.

Never

operate

your

unit

without

the

air

filters.

Dirt

could

be

sucked

in

and

interfere

with

the

function

of

the

unit.

Troubleshooting

Problem

A.

Little

or

no

material

flow

B.

Material

leaking

C.

Atomization

is

too

coarse

D.

Spray

jet

pulsates

E.

Pattern

runs

or

sags

F.

Too

much

overspray

G.

Pattern

is

very

light

and

splotchy.

Cause

1.

Nozzle

clogged.

2.

Suction

tube

clogged.

3.

Material

volume

setting

turned

too

low(

‐

).

4.

Suction

tube

loose.

5.

No

pressure

build

up

in

container.

6.

Air

filter

clogged.

1.

Nozzle

loose.

2.

Nozzle

worn.

3.

Nozzle

seal

worn.

4.

Material

build

‐

up

on

air

cap

and

nozzle

1.

Viscosity

of

material

too

high.

2.

Material

volume

too

large.

3.

Material

volume

setting

too

high

(+).

4.

Nozzle

clogged.

5.

Air

filter

clogged.

6.

Too

little

pressure

build

‐

up

in

container.

1.

Material

in

container

running

out.

2.

Air

filter

clogged.

1.

Applying

too

much

material.

1.

Gun

too

far

from

spray

object.

2.

Too

much

material

applied.

1.

Moving

the

spray

gun

too

fast

Solution

1.

Clean.

2.

Clean.

3.

Increase

volume

setting

(+).

4.

Insert.

5.

Tighten

container.

6.

Change.

1.

Tighten.

2.

Replace.

3.

Replace.

4.

Clean.

1.

Thin.

2.

Decrease

volume

setting

(

‐

).

3.

Decrease

volume

setting

(

‐

).

4.

Clean.

5.

Change.

6.

Tighten

container.

1.

Refill.

2.

Change.

1.

Adjust

material

flow

or

increase

movement

of

spray

gun.

1.

Reduce

distance.

2.

Decrease

volume

setting

(

‐

).

1.

Adjust

material

flow

or

decrease

movement

of

spray

gun.

7

filters