‐

NWG410

‐

25

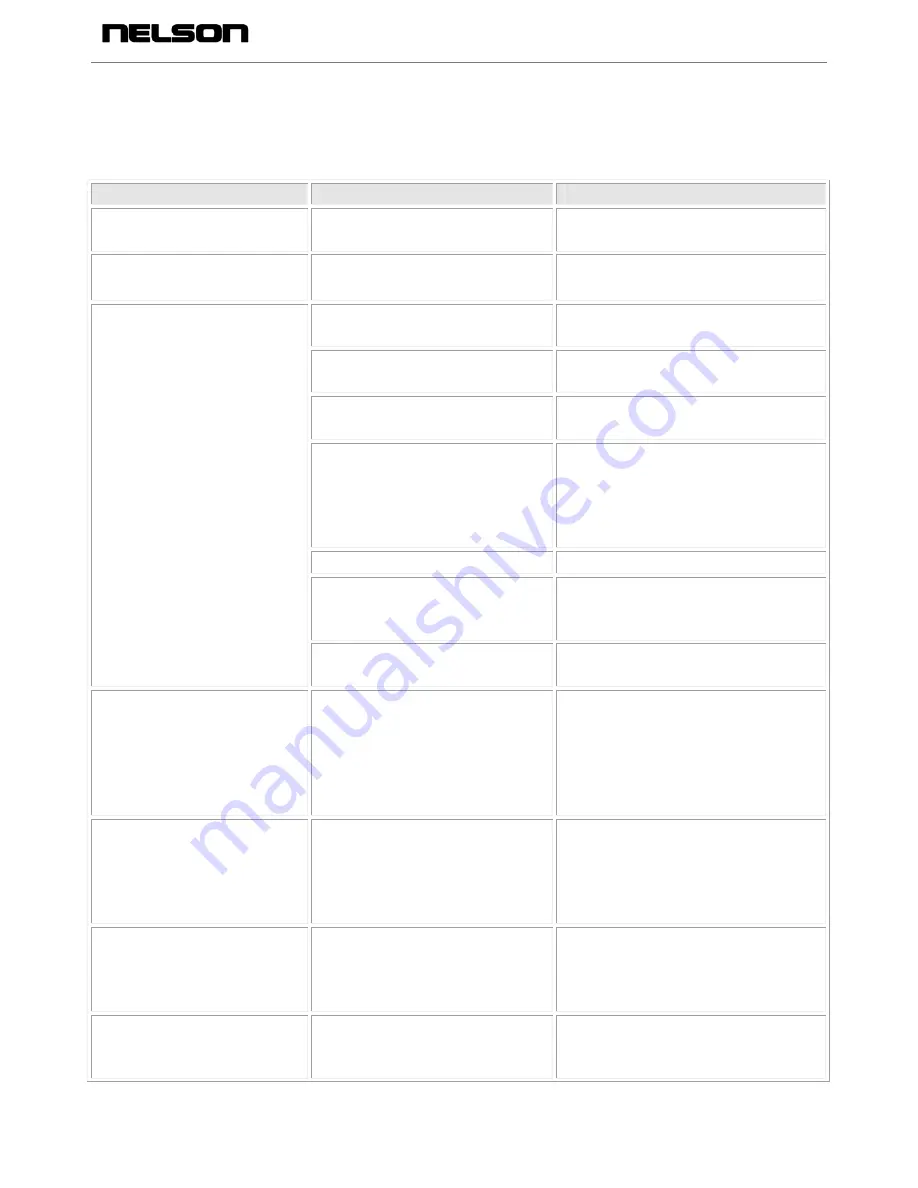

10 TROUBLESHOOTING

How

to

deal

with

any

problems

without

calling

the

after

‐

sales

service

PROBLEM

POSSIBLE

CAUSE

POSSIBLE

REMEDY

LIGHT

L1

DOES

NOT

COME

ON

Mains

power

failure

Check

electrical

mains

connection.

WASHING

PROGRAM

DOES

NOT

START

The

glasswasher

has

not

yet

finished

filling.

Wait

for

the

3

program

lights

to

come

on.

POOR

WASHING

RESULTS

Spray

arm

washing

holes

blocked

by

dirt

or

limescale

Remove

spray

arms

and

clean

them

(9.2

Periodic

checks)

Filter

fouled

See

“Cleaning

the

filter

during

the

day”

Too

little

or

unsuitable

detergent

or

rinse

aid

Check

type

and

quantity

of

detergent.

No

or

not

enough

detergent

or

rinse

aid

being

supplied:

detergent

or

rinse

aid

not

being

taken

from

the

relative

container.

Check

that

the

intake

filter

is

not

fouled.

If

you

are

unable

to

solve

the

problem,

call

the

after

‐

sales

service.

Plates/glasses

badly

arranged

Arrange

plates/glasses

correctly.

Low

washing

temperature

Check

temperature

shown

on

the

display,

call

the

after

‐

sales

service

if

less

than

50°C

Inappropriate

cycle

set

Increase

wash

cycle

duration,

especially

if

dirt

has

dried

on.

INADEQUATE

RINSING

Dynamic

pressure

of

mains

water

insufficient

Spray

arm

nozzles

fouled

Limescale

in

boiler

Check

mains

water

pressure.

Check

that

water

intake

filter

is

not

fouled.

Clean

rinsing

nozzles.

If

you

are

unable

to

solve

the

problem,

call

the

after

‐

sales

service.

STAINS

ON

GLASSES

AND

CUTLERY

Rinse

aid

unsuitable

or

not

being

delivered

correctly.

Water

hardness

above

12°dF

or

large

amounts

of

dissolved

salts

Check

container

of

rinse

aid

and

whether

it

is

suitable

for

the

type

of

mains

water.

If

the

problem

persists,

contact

the

after

‐

sales

service.

WATER

IN

TANK

AFTER

PUMP

‐

OUT

Drain

hose

incorrectly

positioned

or

partially

obstructed.

Check

that

the

glasswasher

drain

hose

and

rain

are

unobstructed

and

the

drain

is

not

too

high

up;

see

connection

diagram.

GLASSES

NOT

PROPERLY

DRIED

Low

rinsing

temperature

due

to

thermostop

OFF

Switch

Thermostop

ON

If

the

problem

persists

call

the

after

‐

sales

service

Summary of Contents for NWG410

Page 1: ...PROFESSIONAL DISHWASHER...