7

IMO-218 EN - Issue 8/2020

Table 4.

Actuator Model Minimum operating time (seconds) for ATEX compliance

RNP 40

0.02

RNP 50

0.02

RNP 63

0.02

RNP 80

0.03

RNP 90

0.03

RNP 100

0.03

RNP 110

0.04

RNP 125

0.04

RNP 150

0.05

RNP 175

0.06

RNP 200

0.06

RNP 250

0.09

RNP 300

0.07

RNP 350

0.09

WARNING:

Valve on which actuator is installed should be earthed properly to

discharge static charge.

2. TRANSPORTATION AND

STORAGE

Make sure that the actuator and associated equipment have not

been damaged during transportation. Store the actuator carefully

before installation, preferably indoors in a dry place. Do not take

it to the installation site or remove the protective caps of ports for

piping until just before installation.

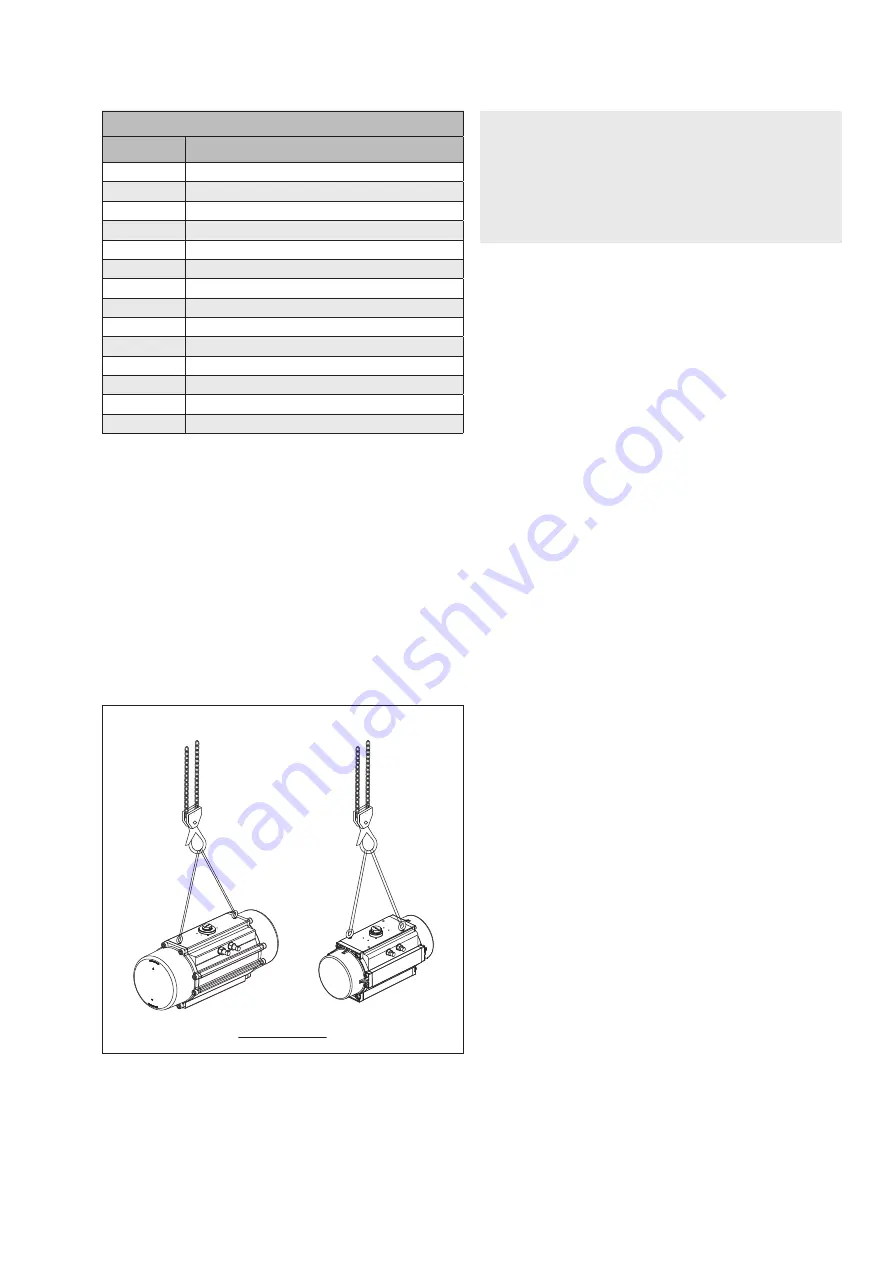

Lift the actuator as shown in Fig. 4: in a horizontal position from the

lifting lugs. Refer to Section 1.4 for weights.

LIFTING ARRANGMENT

RNP 200 / 250

RNP 300 / 350

Figure 4.

Lifting the actuator

Upon receiving the product check the limit actuator and the

accompanying devices for any damage that may have occurred

during transport.

WARNING:

DO NOT USE THE DEVICE IF IT IS DAMAGED DURING

TRANSPORTATION!

IF THE DEVICE HAS SUFFERED DAMAGE DURING

TRANSPORTATION DO NOT INSTALL AND USE IT. IN

CASE OF NOTICING DAMAGE TO THE DEVICE UPON

RECEIVING IT PLEASE CONTACT THE SUPPLIER.

Store the actuator carefully. Storage indoors in a cool, dry place.

Temperature limit for the storing is from 4 °C to 40 °C. The actuator

should be left in its original packing until it is required for the use.

Do not remove protective plugs until installing the actuator.

3. MOUNTING AND

DEMOUNTING

3.1 ACTUATOR GAS SUPPLY

Dry compressed air, nitrogen or natural gas (sweet) can be used

as supply medium, no oil spraying is needed. The air supply

connections are presented in the dimensional drawings in Chapter

9. The maximum supply pressure is depending the selected model.

3.2 INSTALLATION INFORMATION

Before installation please take care of the safety precautions

mentioned in the Section 1.7.

Ensure that the actuator will not be exposed to pressure in excess

to the maximum rating as indicated on the actuator nameplate or

technical documents.

Ensure that throughout the installation that there are no leaks of the

supply media.

The maximum operating temperature for the actuator depends

on individual build of actuator. Refer nameplate for operating

temperature range.

Ensure that the maximum operating temperature as indicated on

the nameplate is not exceeded during operation, transportation or

storage of the actuator.

The environment and surrounding should not affect or limit the

operational safety of the product.

Ensure the product is protected against impact, vibration or any kind

of movement during operation, transportation and storage.

Product should not be installed in hazardous area that is not

compatible with the gas group and temperate class indicated on the

nameplate.

RNP series actuators can be mounted on valve in any desired

position. However it is recommended to align the centerline of the

pneumatic cylinder module along the pipeline.

Ensure proper tightening of fasteners and mounting accessories to

avoid loosening during operation.

All the tubing, fitting and actuation media should be free from

contamination and filtered to the desired level. Quality of media

should be as per ISO 8573-1 [5:3:4]. For additional information

consult Neles.

Ensure proper adjustments of the stopper bolt to desired opening

and closing of the valve.

Summary of Contents for Easyflow RNP Series

Page 27: ...27 IMO 218 EN Issue 8 2020...