7

5. Technical data

Model

KIMO 24V

Force exerted by thrust (F

N

)

100N

Force exerted by traction (F

N

)

200N

Strokes (S

V

)

70, 125, 170, 210 mm

Power supply voltage (U

N

)

24 V

SELV

Rated absorbed current (I

N

)

0,36A

Power absorbed at nominal load (P

N

)

8,6W

Electrical insulation

Class III

No load speed

5,5 mm/s

Duration of no load stroke

(210 mm)

38 s

Type of service (D

R

)

5 cycles

Operating temperature

- 5 + 65 ºC

Protection index for electrical devices

IP32

Adjustment of connection to window frame

Automatic definition of position

Parallel powering of two or more motors

YES

(max 20 actuators)

Operation with BK-LOCK electromechanical

lock

Yes

Synchronised function

Not foreseen

Holding nominal force

(it can vary according to

the chosen brackets)

1.700N

Stroke-end at opening

Electronic by dip-switch

Stroke-end at closing

At absorption of power

Chain exit

Central

Length of power cable

2 m

Dimensions

29x29x310 mm

Weight

0,720 Kg

The data indicated in these figures is not binding and is subject to variation without notification.

6. Id plate and marking data

The KIMO actuators have CE marking and comply with the Standards listed in the

Declaration of Conformity. They also come with a Declaration of Incorporation, due

to their classification by the Machinery Directive as “partly completed machines”.

Both declarations are included in the final pages of this manual.

The plate data is displayed on an adhesive label placed on the outside of the casing,

which must remain intact and visible.

The main information it displays includes: manufacturer's address, product name -

model number, technical characteristics, production date and serial number.

In the event of a complaint, please indicate the serial number (SN) displayed on the

label.

An explanation of the symbols used on the label to abbreviate the technical

characteristics is given in the table in the chapter on “TECHNICAL DATA”.

8

7. Electric power supply

The KIMO actuator is powered with a voltage of 24V

SELV. The power supply

cable has three conductors: the first conductor

R

ED

“1”

that should be connected to

the + (positive) C

LOSES

the window; the second conductor

B

LACK

“2”

that should be

connected to the + (positive) O

PENS

the window; the third conductor

G

REEN

“3”

is

the conductor used for the BK-LOCK control communication signal

.

The 24V

low-voltage actuators can be powered using a station with emergency

batteries or a security power supply unit with an output voltage of 24V

(min. 20.4V,

max. 28,8V

), that is to say, sized based on the number of actuators connected.

7.1.

Selecting the cross-section of the power supply cables

It is necessary to check the cross-section of the cable, which should be calculated

based on the length of the cable itself. The table below specifies the maximum length

of the cables for connection of a motor.

CABLE SECTION

Actuator fed at

24V

0.50 mmq

~40 m

0.75 mmq

~60 m

1.00 mmq

~80 m

1.50 mmq

~120 m

2.50 mmq

~200 m

4.00 mmq

~320 m

6.00 mmq

~480m

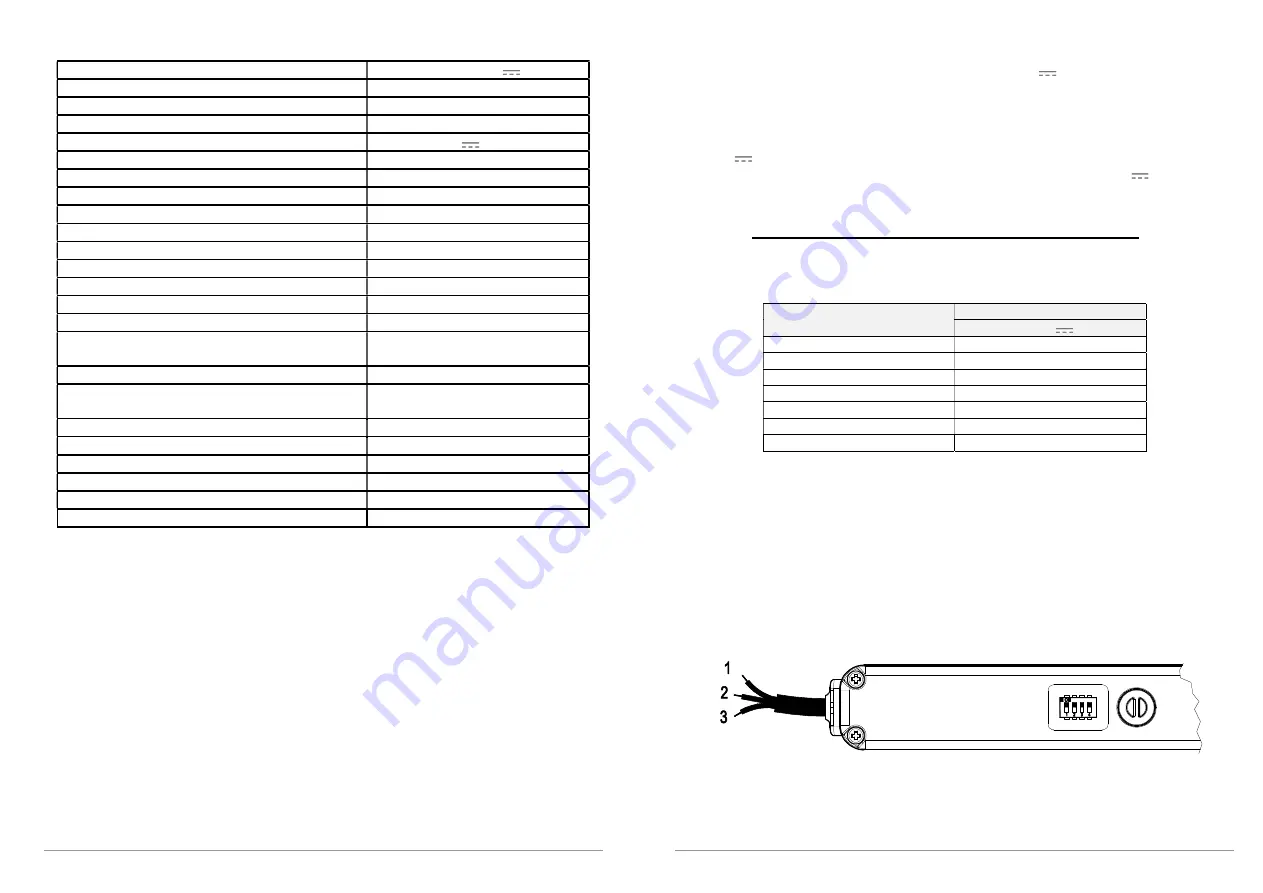

8. Electrical connection

The machines are equipped with a power supply cable constructed in compliance

with safety standards and restrictions on radio-frequency interference.

The power supply cable - with conductors having a cross-section of 0.5 mm² - is 2

meters long with different colored conductors, as follows

1

–

R

ED

-coloured conductor;

2

–

B

LACK

-coloured conductor;

3

–

G

REEN

-coloured conductor:

For harness, please follow this diagram: