BTR-S

ERIES

O

PERATION

& M

AINTENANCE

M

ANUAL

12838 Stainless Drive, Holland, MI 49424

Phone: 616/399-5600 Fax 616/399-3084

Copyright 2018 BRAWN Mixer

www.BRAWNMIXER.com

Page 6 of 9

11/27/2018

ELECTRIC MOTORS, Cont.

INSULATION RESISTANCE

Check insulation resistance periodically. Any approved

method of measuring insulation resistance may be used,

provided the voltage across the insulation is at a safe

value for the type and condition of the insulation. A hand

crank megger of not over 500 volts is the most

convenient and safest method. Standards of the Institute

of Electrical and Electronics Engineers, Inc., recommend

that the insulation resistance of the stator windings at 75°

C, measured at 500 volts dc, after one minute should not

be less than:

Rated Voltage of M 1000

=

Insulation Resistance

1000

in Megohms

This formula is satisfactory for most checks. For more

information, see IEEE Standard No. 43 “Recommended

Practice for Insulation Resistance Testing of AC Rotating

Machinery.”

CLEANING

WARNING

Do not attempt to clean the motor while it is operating.

Contact with rotating parts can cause severe personal

injury or property damage. Stop the motor and lock out

switch before cleaning.

The motor exterior must be kept free of oil, dust, water,

and chemicals. For fan cooled motors, it is particularly

important to keep the air intake openings free of foreign

material. Do not block air outlet or inlet.

On non-explosion-proof TEFC motors, a removable plug

in the bottom center of the motor frame or housing

permits removal of accumulated moisture. Drain

regularly.

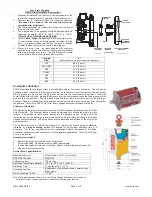

MAINTENANCE / LUBRICATION

Gear units should have the oil changed every 10,000

hours or 2 years. If synthetic lubricant is used, it should

be changed every 20,000 hours or 4 years. For adverse

operating conditions, the interval should be shorter.

DO

NOT MIX SYNTHETIC AND MINERAL BASE OILS.

Units should be checked periodically for increased noise,

surface temperature, vibration, shaft movement and

amperage draw. Units with inspection covers should not

be operated with the inspection cover removed.

CAUTION

Oil should be changed more often if reducer is used in a

severe environment. (i.e. dusty, humid)

All reducers are shipped from the factory properly filled

with lubricant and all plugs are installed according to the

mounting position given on the reducer nametag.

Acceptable oil level is within ½ inch of the bottom of the

fill plug threads. Consult the sticker adjacent to the fill

plug to determine the type of lubricant installed at the

factory. Standard lubricant is ISO VG220 mineral-based

oil. However, some units have special lubricants

designed to operate in certain environments or to extend

the service life of the lubricant. If in doubt about which

lubricant is needed, contact Brawn.

TABLES 2 and 3

offer suggestions on the viscosity and

manufacturers of recommended lubricants.

CAUTION

In the Food and Drug Industry (including animal food),

consult the lubrication supplier for recommendation of

lubricants which are acceptable to the Food and Drug

Administration and/or other authoritative bodies having

jurisdiction. Factory supplied oil is not suitable for these

applications or this industry.

Summary of Contents for BTR Series

Page 2: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 4: ......

Page 27: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 28: ......