INSTRUCTIONS BOOK FOR FURNACE H1

17

4. HANDLING MANUAL

We have a

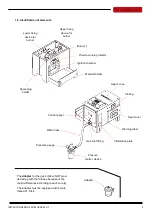

Control panel

which will allow us to control the performance of the furnace H1 and which will

enable us to maintain complete control of the m¡achine in a simple and intuitive way.

4.1. Gas valve

The

Control panel

has got one valve for the opening of the gas entrance to the

Burner

. This valve is marked

with number 1. The operator controls them in order to obtain more on less gas flow.

4.2. Pushbuttons

There are two puhbuttons in the

Control panel:

- The pushbutton for

Electronic switching

is the one that activates the spark plug and generates the spark to

light up the

Burner.

- The

Thermocouple pushbutton

is the one that opens the valve the get the thermocouple activated. This

valve opens the path to the

Gas valve 1

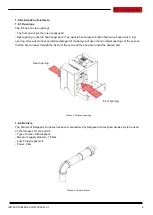

4.3. Pressure regulator and manometer

The

Pressure regulator

allows us to control the working pressure between 0,1 and 1,5 bar, Nargesa suggests

to work at a pressure from 0,2 to 1 bar. The

Manometer

will indicate the pressure value on the furnace circuit.

Thermocouple

pushbutton

Electronic switching

Gas valve 1

Summary of Contents for H1

Page 2: ...Thanks for choosing our brand www nargesa com...

Page 25: ...Tecnichal Annex Horno H1 List of parts Location of components Gas layout...

Page 27: ...INSTRUCTIONS BOOK FOR FURNACE H1 A 3...

Page 28: ...INSTRUCTIONS BOOK FOR FURNACE H1 A 4...

Page 29: ...INSTRUCTIONS BOOK FOR FURNACE H1 A 5...

Page 30: ...INSTRUCTIONS BOOK FOR FURNACE H1 A 6...

Page 31: ...INSTRUCTIONS BOOK FOR FURNACE H1 A 7 Location of components...

Page 32: ...INSTRUCTIONS BOOK FOR FURNACE H1 A 8 Gas layout...