- 16 -

VERTICAL BROACHER BM25

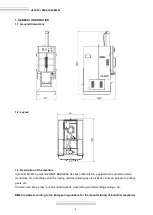

Piston up

Piston down

Piston

2nd operation

1st operation

3rd operation

(A) Bushing

(B) Thick

(C) Broach

(D) Piece

5.3. Samples to make a correct broaching operation

1 - Place the piece in the middle of the table.

2 - Insert the bushing.

3 - Place the broach in the bushing, lubricate abundantly in order to achieve a perfect broaching opeartion,

especially during the first operation.

4 - Get the piston down from 20 to 40 mm until having the broach inserted in the bushing, then slightly raise

up the piston so the broach recovers its vertical position and then repeat the same procedure 2 or 3 times

until the broach overtakes the piece and it could be taken by the down part of the piece.

5 - It will be necessary to gradually insert 1, 2 or 3 thick parts depending on the broachsince these are the

ones that give the exact depth.

6 - Clean up all steel wool from the broach once the broaching operation is finished (it is very important for

the broach not to be broken).

7 - Causes of an incorrect broaching.

- The use of oil in bad conditions.

- Do not place the broach in vertical position.

- Do not intercalate the piston thrust.

Depending on the carve depth, request 6. TABLE OF CHARACTERISTICS OF BRUSHES

Summary of Contents for BM25

Page 2: ...Thank you for choosing our machines www nargesa com...

Page 18: ...18 VERTICAL BROACHER BM25 6 TABLE OF CHARACTERISTICS OF BRUSHES 6 1 Millimeter keyway broaches...

Page 19: ...19 6 2 Inches keyway broaches...

Page 20: ...20 VERTICAL BROACHER BM25...

Page 35: ...A3 VERTICAL BROACHER BM25 A1 List of parts...

Page 36: ...A4...

Page 37: ...A5 VERTICAL BROACHER BM25...

Page 38: ...A6...

Page 39: ...A7 VERTICAL BROACHER BM25...

Page 40: ...A8 A2 Piston assembly...

Page 41: ...A9 VERTICAL BROACHER BM25...

Page 42: ...A10 A3 Hydraulic group...

Page 43: ...A11 VERTICAL BROACHER BM25...

Page 44: ...A12...

Page 45: ...A14 A4 Electric box...

Page 46: ...A15 VERTICAL BROACHER BM25...

Page 47: ...A16...