EN

WWW.NAKAYAMATOOLS.COM

16

Transporting /storage

Troubleshooting

WARNING:

When transporting the tiller, turn the fuel valve OFF and keep the tiller level to prevent fuel

spillage. Fuel vapours or spilled fuel may be ignited.

Before storing the unit for an extended period:

1. Be sure the storage area is free of excessive humidity and dust.

2. Drain the fuel.

WARNING:

Gasoline is highly flammable and explosive under certain conditions. Do not smoke or

allow flames or sparks in the area.

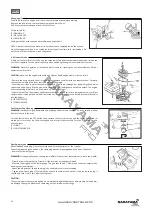

- With the fuel valve turned OFF, remove and empty the fuel strainer cup.

- Turn the fuel valve ON and drain the gasoline in the fuel tank into a suitable container.

- Replace the fuel strainer cup and tighten securely.

- Drain the carburettor by loosening the drain knob. Drain the gasoline into a suitable container.

3. Pull the starter grip until resistance is felt. Continue pulling until the notch on the starter puller aligns

with the hole on the recoil starter.

At this point, the intake and exhaust valves are closed and this will help to protect the engine from

internal corrosion.

4. Change engine oil.

5. Cover tiller with plastic sheet.

Do not place the tiller with the handlebars on the ground. It will cause the oil entering the cylinder or

the fuel spillage.

(1) O-RING

(2) FUEL STRAINER CUP

(3) DRAIN KNOB

(1) Align the notch on the starter pulley with the

hole at the top of recoil starter .

When the engine will not start:

·Is there enough fuel?

·Is the fuel valve on?

·Is the engine switch ON?

·Is gasoline reaching the carburettor?

- To check, loosen the drain knob with the fuel valve ON. Fuel should flow out freely.

- Retighten drain knob.

WARNING:

If any fuel is spilled, make sure the area is dry before testing the spark plug or starting the

engine. Fuel vapour or spilled fuel may ignite.

(1) Fuel valve

(2) ON

(3) DRAIN KNOB

- Is there a spark at the spark plug?

Remove the spark plug cap. Clean any dirt from around the spark plug base, then remove the spark plug.

Install the spark plug in the plug cap.

Turn the engine switch on.

Grounding the side electrode to any engine ground, pull the recoil starter to see if sparks jump across the gap.

If there is not spark ,replace the plug.

If OK, try to start the engine according to the instructions.

·If the engine still does not start, take the tiller to an authorized dealer.

Summary of Contents for 042808

Page 1: ...en el WWW NAKAYAMATOOLS COM ART NO MB6100 042808...

Page 17: ...EL WWW NAKAYAMATOOLS COM 18 1 2 3 4 1 2 3...

Page 18: ...EL WWW NAKAYAMATOOLS COM 19 4 5 1 2 3 4 5 6 7 8 9 10 11 12 13 14 1 2 3 4 5 6...

Page 20: ...EL WWW NAKAYAMATOOLS COM 21 SAE 20W 50 SAE30 1 2 MAX 3 MIN 1 1 95...

Page 22: ...EL WWW NAKAYAMATOOLS COM 23 1 1 2 3 4 1 2 3...

Page 23: ...EL WWW NAKAYAMATOOLS COM 24 1 2 3 6 8o 300mm 1 2...

Page 25: ...EL WWW NAKAYAMATOOLS COM 26 20 3 50 6 100 300 1 2 2 2 2 1 2...

Page 26: ...EL WWW NAKAYAMATOOLS COM 27 0 6 L 1 2 3 1 2 OFF ring ON 1 O RING 2 0 7 0 8mm 1 2 1 4 1 2...

Page 27: ...EL WWW NAKAYAMATOOLS COM 28 3 8mm 1 2 5 10mm 1 2 3 60 65mm 2 4 2 6 in 1 2 1...

Page 28: ...EL WWW NAKAYAMATOOLS COM 29 1 2 OFF ON 3 4 5 1 O RING 2 3 1 ON OFF ON ON 1 2 ON 3 ON OFF ON...

Page 29: ......